A kind of preparation method of latex product not easy to bloom and stick

A product and latex technology, applied in the field of latex product preparation, can solve problems such as waste, difficulty in meeting product performance requirements for compounding agents, and molecular chain breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 A kind of preparation method of the latex product that is not easy to bloom and stick

[0042] Include the following steps:

[0043] (1) Preparation of primary natural latex products

[0044] Using natural rubber latex imported from Thailand as raw materials, first grind 0.9phr of sulfur, 1.4phr of accelerator ZDC, and 1phr of anti-aging agent 264 into a 50% dispersion, and add it to 100phr of 60% natural latex raw rubber in proportion, and then Add 0.6phr casein and 0.3phr potassium hydroxide (KOH) as stabilizers, heat up the compounded latex to 60°C within a certain period of time for pre-vulcanization, and let it stand for 15 hours to mature, and the pre-vulcanized product can be obtained. of natural rubber latex;

[0045] Add 1.2phr active agent zinc oxide (ZnO) and 2phr thickener sodium polyacrylate to the pre-vulcanized latex;

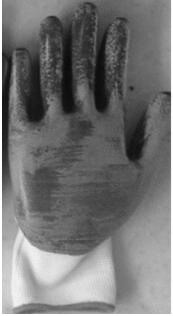

[0046] Finally, the glove mold can be used to impregnate the coagulant, dip, form, and vulcanize to obtain the natural late...

Embodiment 2

[0054] Embodiment 2 A kind of preparation method of the latex product that is not easy to bloom and stick

[0055] Include the following steps:

[0056] (1) Preparation of primary natural latex products

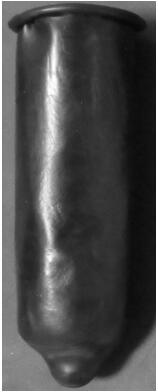

[0057] Using natural rubber latex imported from Thailand as raw materials, first grind 1.6phr of sulfur, 0.7phr of accelerator ZDC, 0.8phr of active agent ZnO, and 1phr of anti-aging agent 264 into a 50% dispersion, and add it to 60% of 100phr in proportion Add 0.3 phr of potassium hydroxide (KOH) to natural latex raw rubber as a stabilizer, heat up the compounded latex to 60°C within a certain period of time for pre-vulcanization, and let it stand for 17 hours to mature. Vulcanized natural rubber latex; then the condom mold can be used to soak the coagulant, dip, mold and vulcanize to obtain the natural rubber latex condom product.

[0058] (2) Hypochlorite treatment

[0059] Put the product in 5% calcium hypochlorite for 5 minutes.

[0060] (3) Acetic acid treatment

...

Embodiment 3

[0064] Embodiment 3 A kind of preparation method of the latex product that is not easy to bloom and stick

[0065] The technological process is the same as that in Example 1, except that the concentration of the calcium hypochlorite solution is changed to 10%, and the treatment time is 1 min. Finally, a natural rubber latex glove product that is left for one year without frosting or sticking is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com