Cutting chip breaking device with active power

A power and chip breaking technology, applied in auxiliary devices, turning equipment, manufacturing tools, etc., can solve the problems of tool damage, low chip breaking efficiency, and easy damage to machine tools, so as to improve efficiency and reliability, and achieve good chip breaking effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

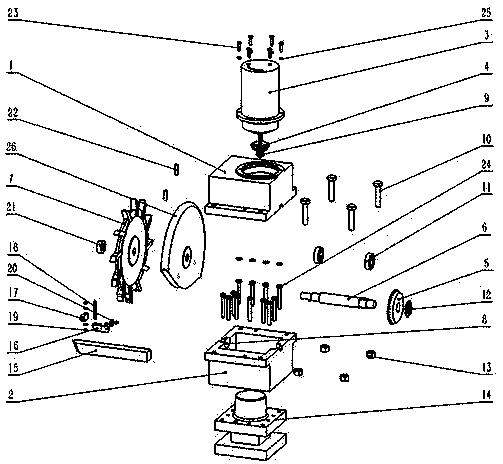

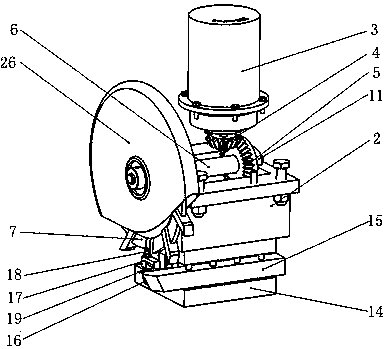

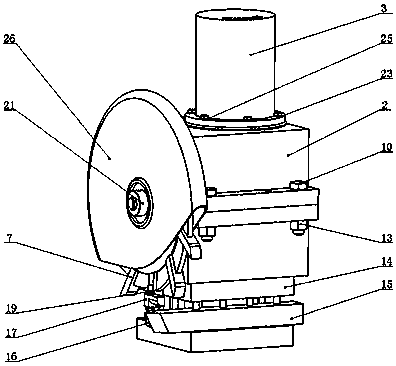

[0029] like Figure 1-7 As shown, a cutting chip breaking device with active power includes an upper casing 1, a lower casing 2, a DC speed regulating motor 3, a small bevel gear 4, a large bevel gear 5, an output shaft 6, and a three-sided edge milling cutter 7. Bearing 11, protective cover 26, base 16, "L" type block 17, guide stud 18; wherein DC speed regulating motor 3 is the power source of the whole chip breaking device with active power; output shaft 6 is The power is provided by the rotation of the side and side milling cutter.

[0030] A bearing seat hole 8 is processed on both sides of the upper and lower shells, and two bearings 11 are respectively installed in the two bearing seat holes 8; the output shaft 8 is supported by two bearings 11, and a three-side milling cutter 7 is installed on one end, and the middle part The large bevel gear 5 is installed; the small bevel gear 4 is installed at the output end of the DC speed regulating motor;

[0031] There are 8 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com