Double-tab rectification implementing method

A realization method, bipolar lug technology, applied in the direction of electrode manufacturing, electrochemical generator, electrical components, etc., can solve the problems that affect the product accuracy, easy to sag, and the tabs cannot sag in the same range, so as to achieve good precision and intelligence high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

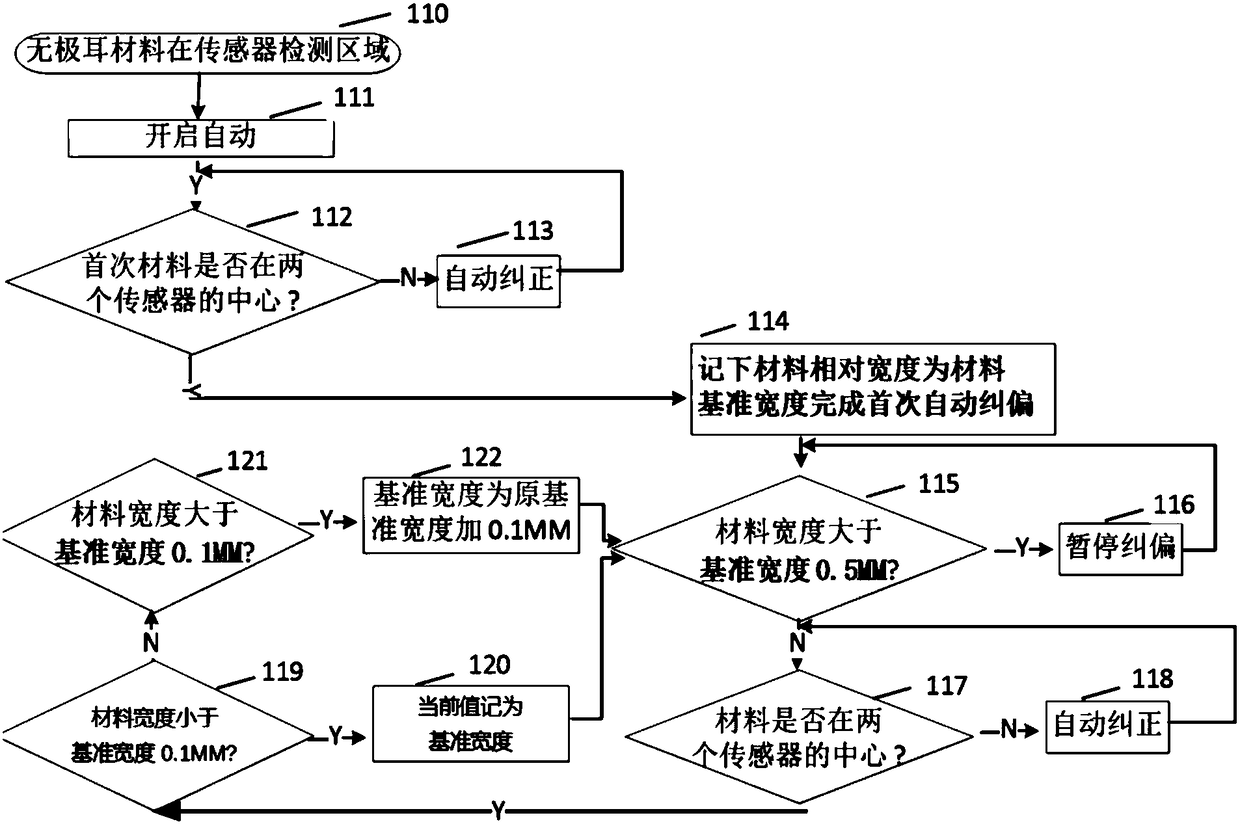

[0018] Such as figure 1 As shown, a bipolar ear deviation correction implementation method includes the following steps:

[0019] Step 1. Before the automatic deviation correction, the non-tab material is in the sensor detection area. At this time, the automatic deviation is turned on. After confirming the automatic deviation correction, the material completes the first automatic deviation correction at the center of the two sensors, and the relative width of the material is recorded as the material reference width;

[0020] Step 2. If the lug enters the detection range of the sensor, judge whether the material width is greater than the material reference width. If the material width is greater than the material reference width during deviation correction, suspend deviation correction, otherwise continue deviation correction until the material is in the center of the two sensors;

[0021] Step 3. Query whether the actual width of the material becomes smaller. If it becomes sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com