Automatically-welded adjustable adaptive conducting brush device

An automatic welding and adjustable technology, applied in the direction of circuits, connections, current collectors, etc., can solve problems affecting welding efficiency, improve welding efficiency and quality, avoid winding and interference, and reduce the risk of downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

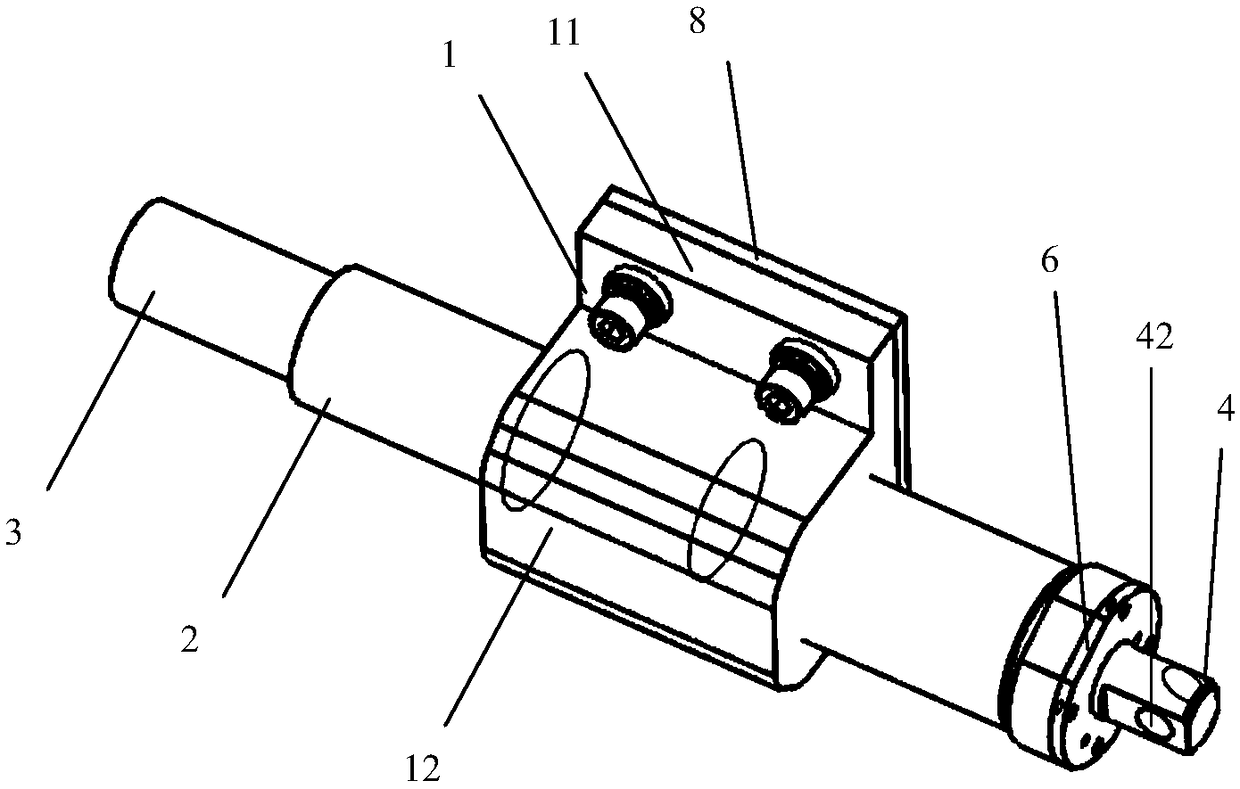

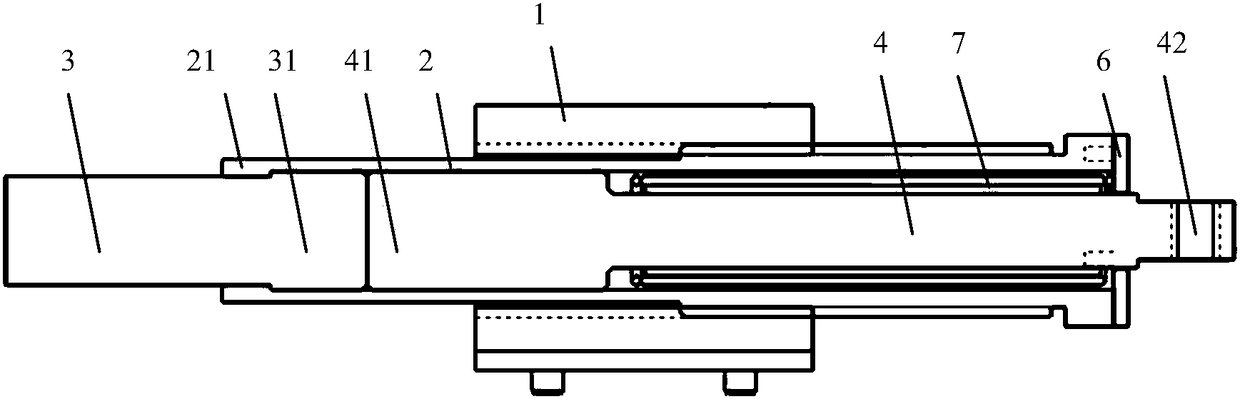

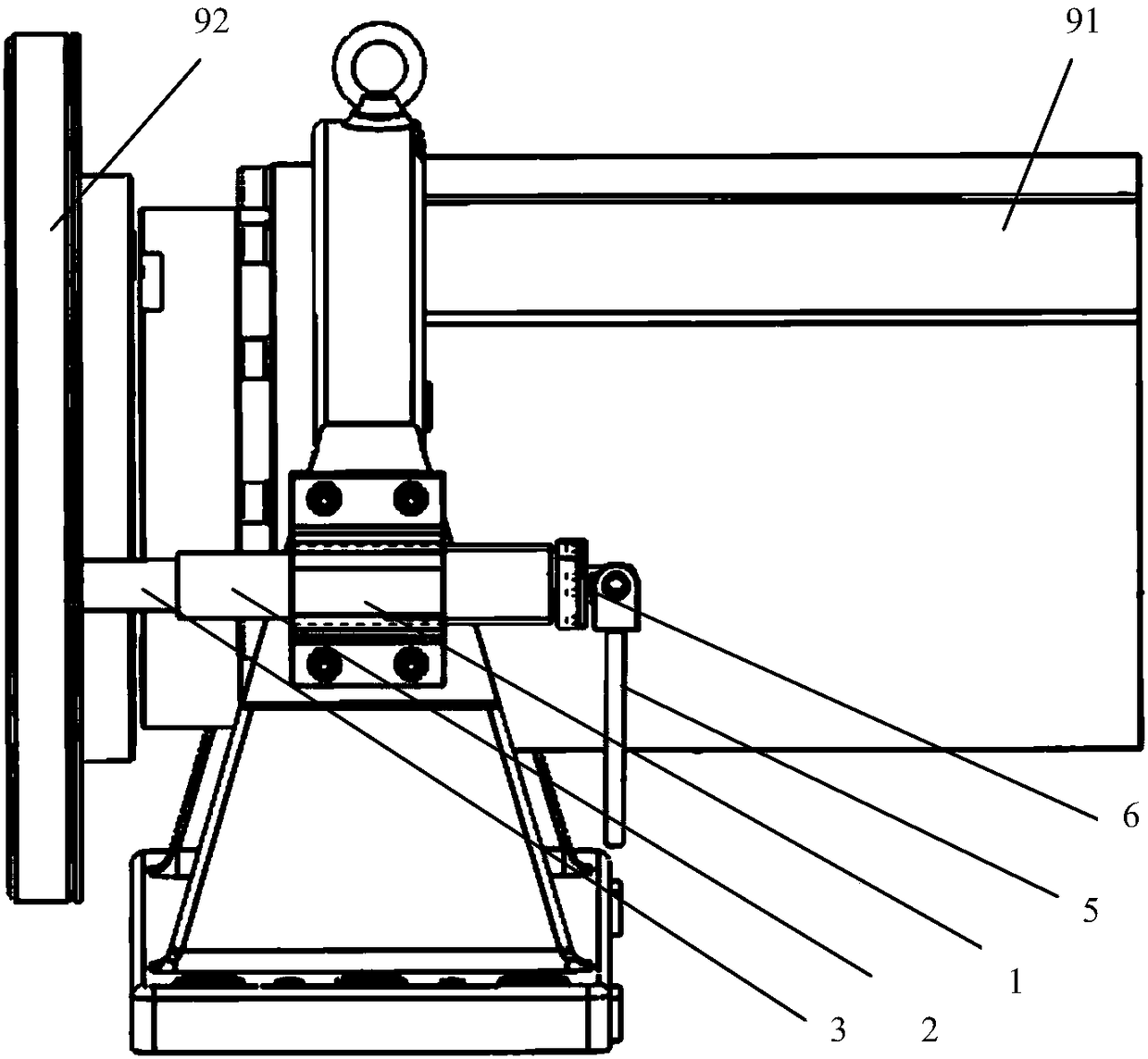

[0029] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 3 As shown, the fixed seat 1 has an integrated structure. The fixed seat 1 includes a columnar adjusting part 11 and a plate-shaped fixing part 12. The side of the adjusting part 11 is connected with the fixing part 12. The screw rod 2 is threadedly connected to the adjusting part 11, and the fixing part 12 is fixedly connected to the housing 91 of the turntable or positioner.

[0030] In a further embodiment of the present invention, the end of the conductive mandrel 4 close to the ground wire 5 is provided with a through hole 42 for fixing the ground wire 5 , and the through hole 42 is opened along the radial direction of the conductive mandrel 4 .

[0031] In a further embodiment of the present invention, an insulating pad 8 is further provided between the fixed seat 1 and the housing of the turntable or positioner. Insulation pad 8 is used for isolating electric current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com