Gas burner with multiple flame rings for cooking hobs

A gas burner and burner technology, which is applied in the directions of gas fuel burners, burners, combustion types, etc., can solve problems such as the significant overall size of the burner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

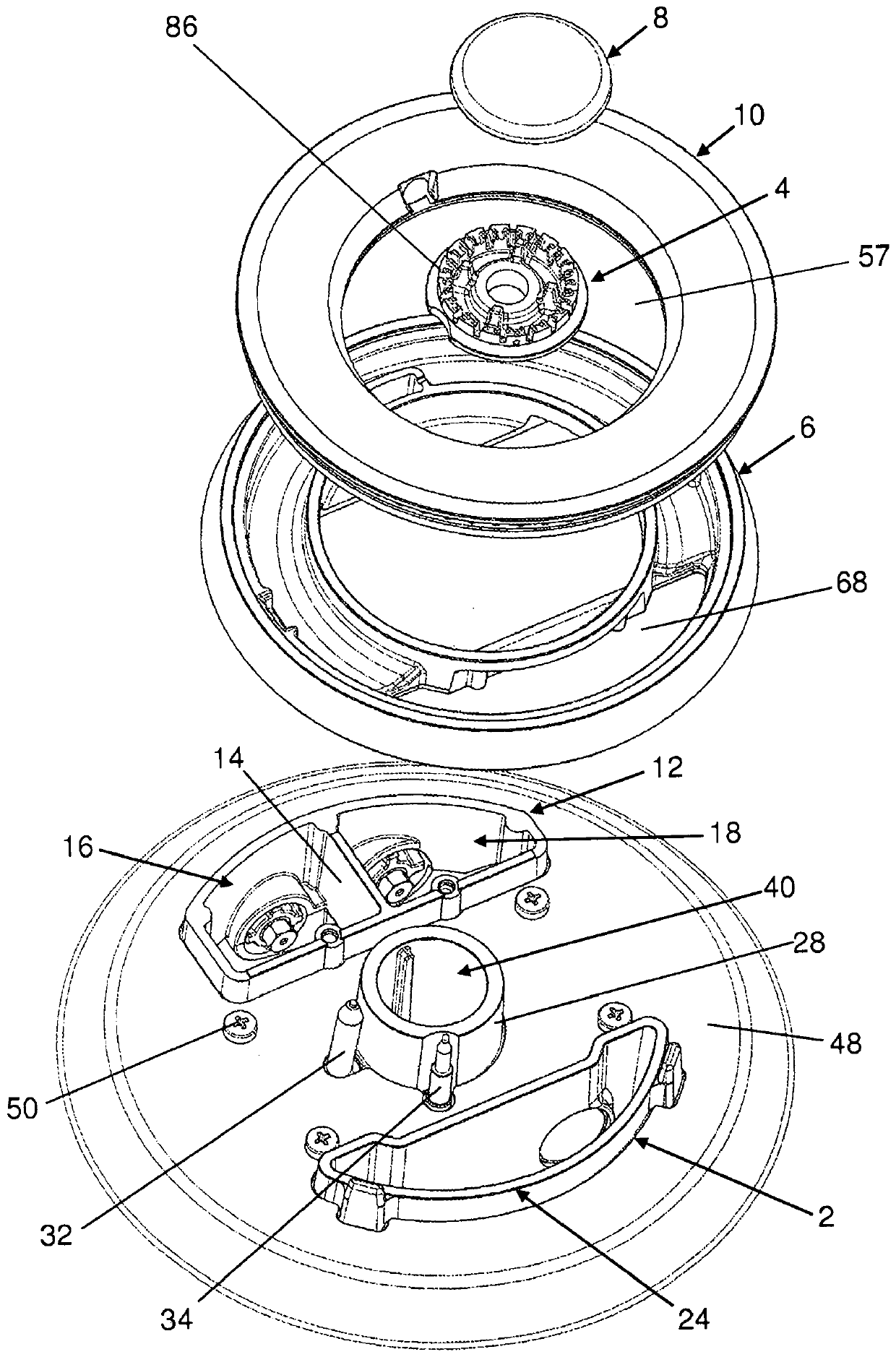

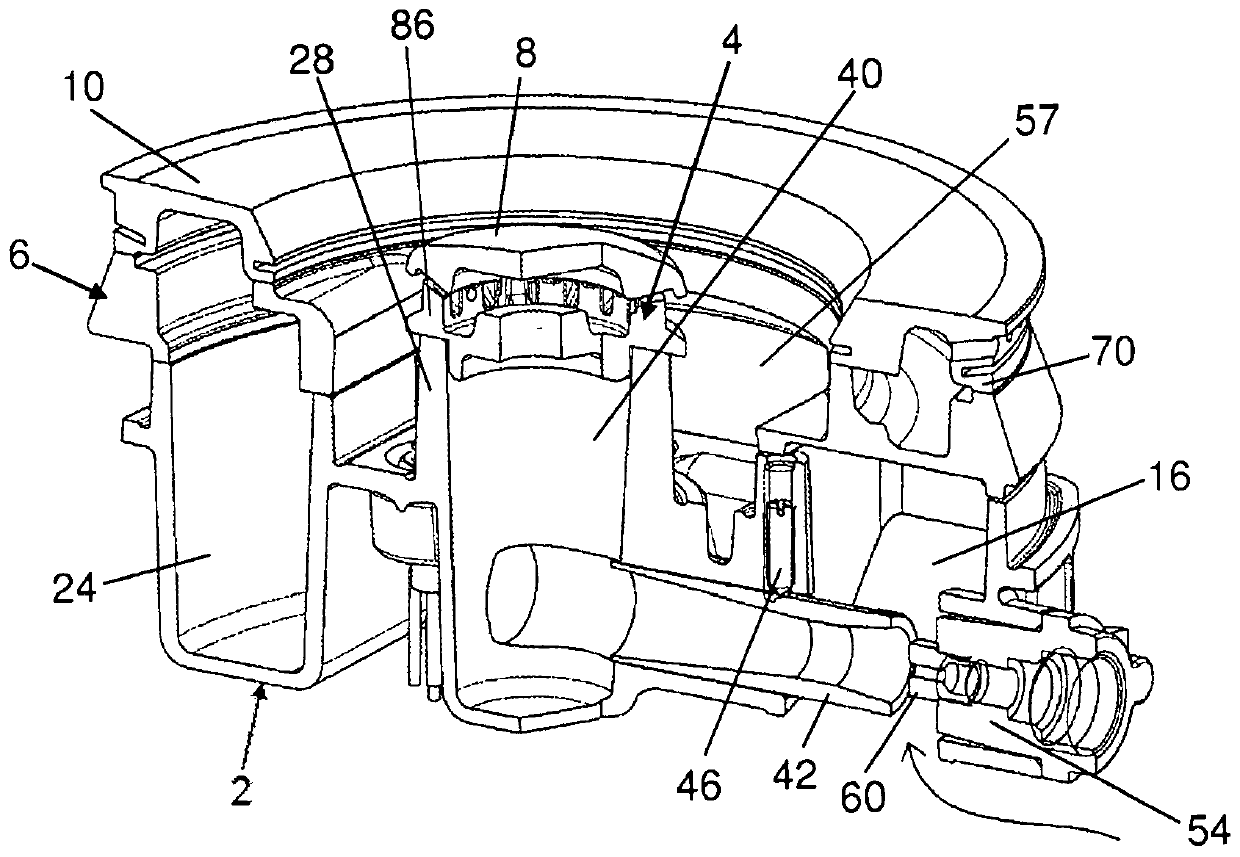

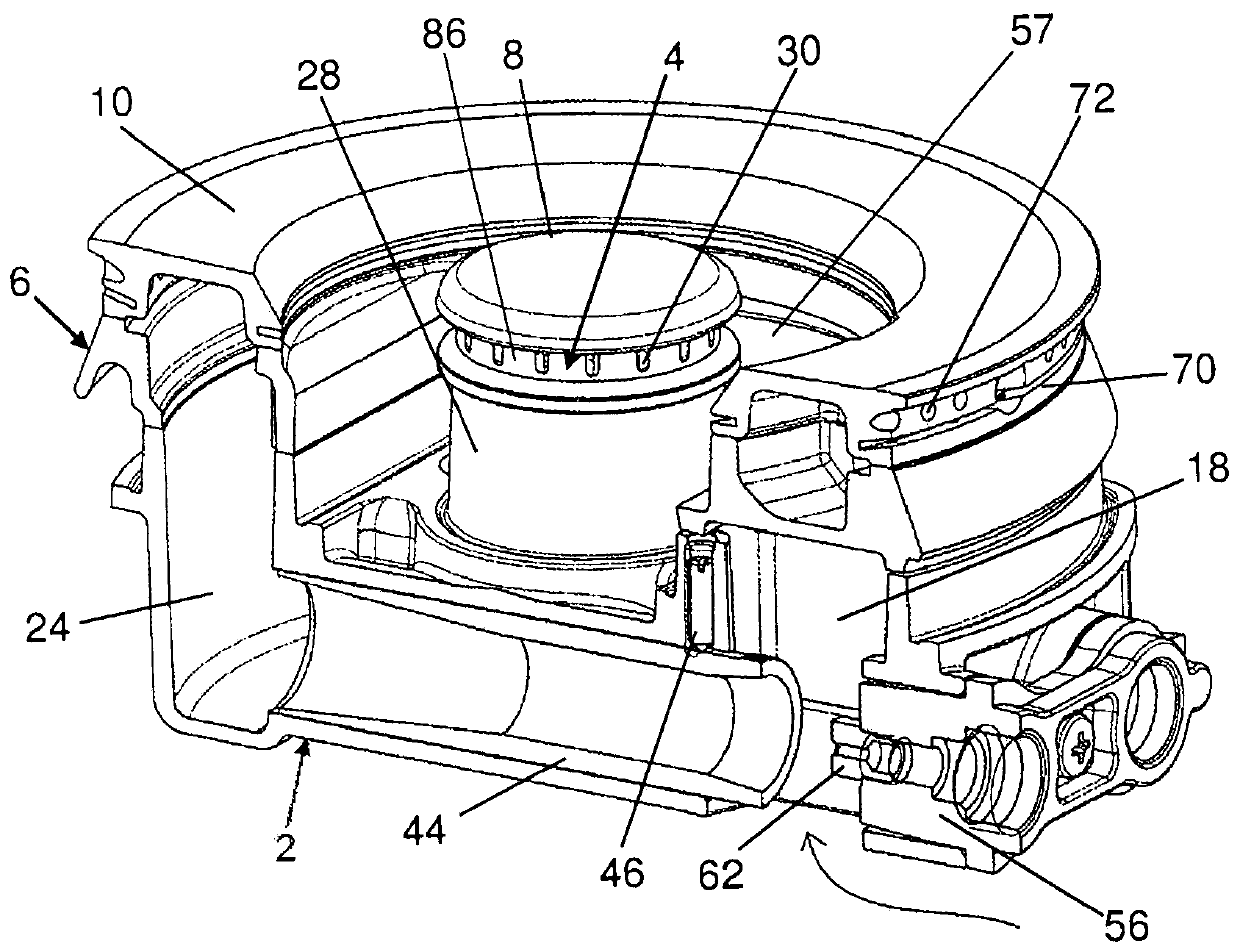

[0044] As shown in the figure, the burner according to the present invention includes:

[0045] - the lower burner body 2 intended to be applied under the metal plate 48 of the cooktop and fixed to said metal plate 48 by eg screws 50,

[0046] - the first burner base 4 for the central flame ring integrated with the lower burner body 2,

[0047] - a second burner base 6 for one or two annular flame rings, conveniently constituted by a separate body from the first burner base 4,

[0048] - round cover 8 for first burner base 4,

[0049] - An annular cover 10 for the second burner base 6 .

[0050] Advantageously, the lower body 2 consists of a single part. Conveniently, it has an irregular shape but preferably has an outer edge inscribed in the circumference. Preferably, the lower body 2 has a shape in plan view that can be conceived to be produced by an almost circular shape but lacks two diametrically opposed circular segments at the edge 7 that reinforces the two opposed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com