Children seat and electric leg supporting mechanism thereof

A technology for child seats and leg rests, applied in child seats, child chairs, children's furniture, etc., can solve the problems of insufficient contact area, poor seat cushion riding experience, reduced safety, etc., to achieve easy operation and satisfactory comfort effect of enhancing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the drawings and specific embodiments.

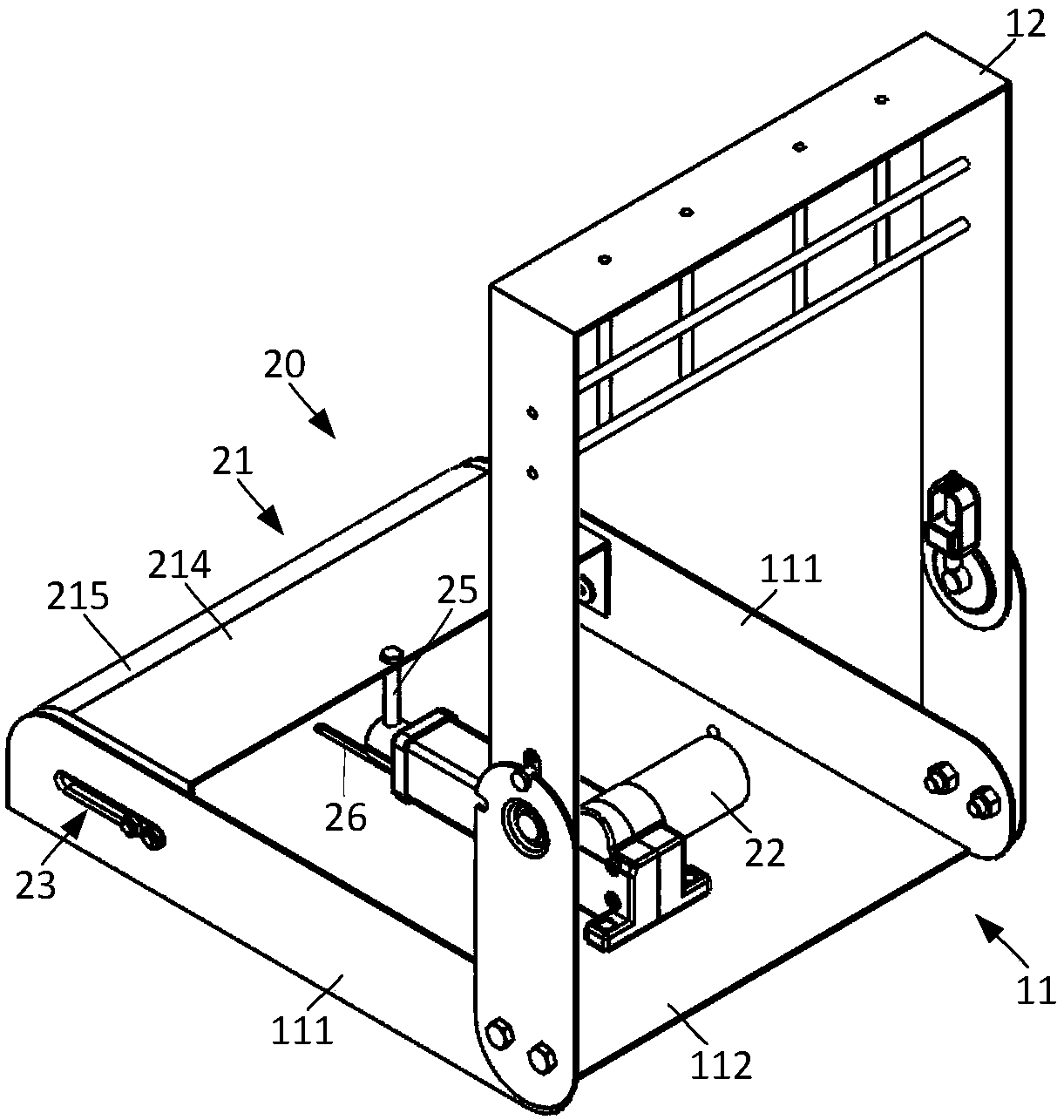

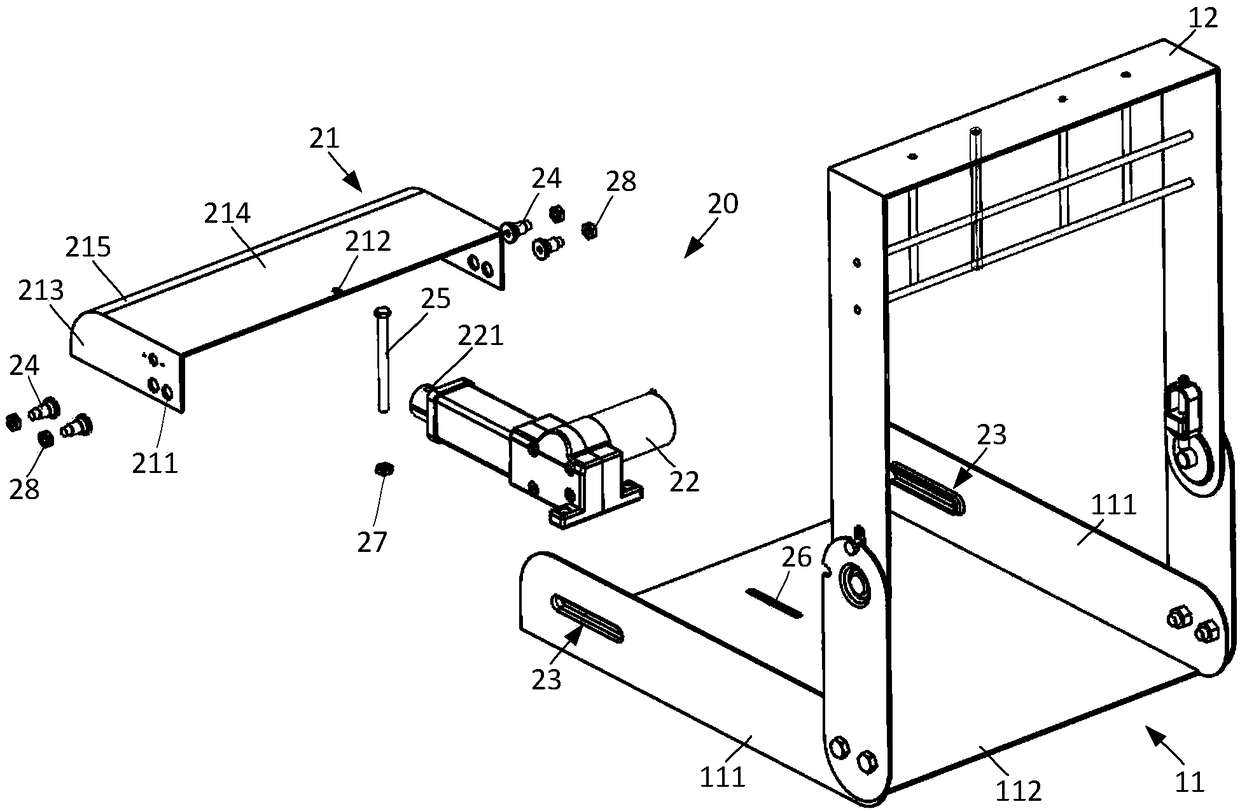

[0028] Refer to figure 1 , The present invention provides a child seat and its electric leg rest mechanism, which utilizes the sliding adjustment of the leg rest mechanism to achieve the purpose of adjusting the length of the seat cushion, and solves the problem that the existing seat cushion length cannot meet the riding needs of children with long legs. On the one hand, the riding experience is poor, and on the other hand, the cushioning contact area of the cushion cannot reach the maximum range, which makes the safety in a collision accident lower. The leg support mechanism of the present invention can not only meet the comfort requirements of the child occupants, but also improve the safety of the child seat. The leg support mechanism is driven to slide by the driving structure, and the position of the leg support plate is locked by leaning on the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com