a maintenance technique

A kind of technology, wire rope technology, applied in the field of maintenance, can solve problems such as troublesome, waste of manpower, etc., to achieve the effect of ensuring safety performance, increasing safety, and conveniently applying lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below through specific implementations:

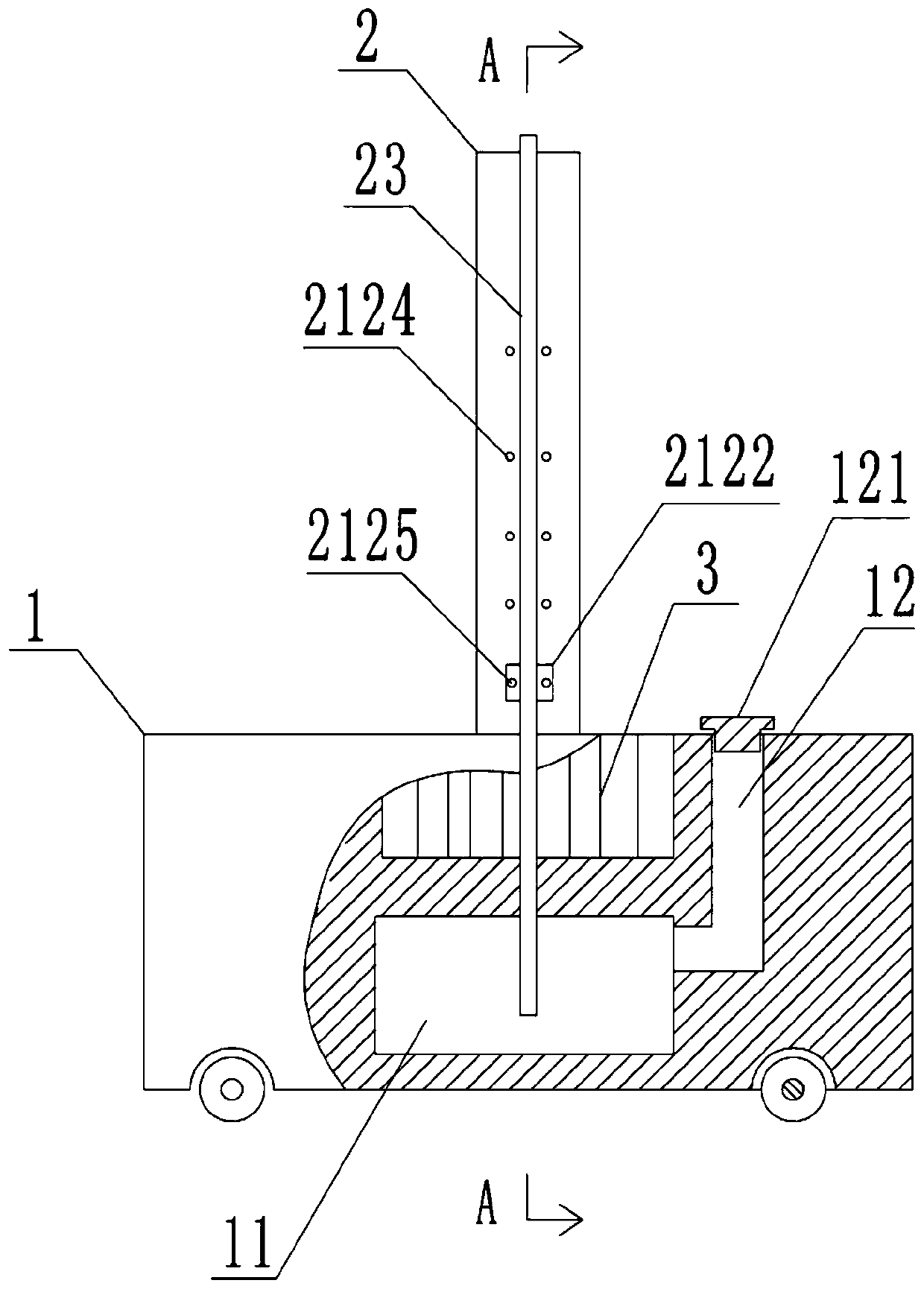

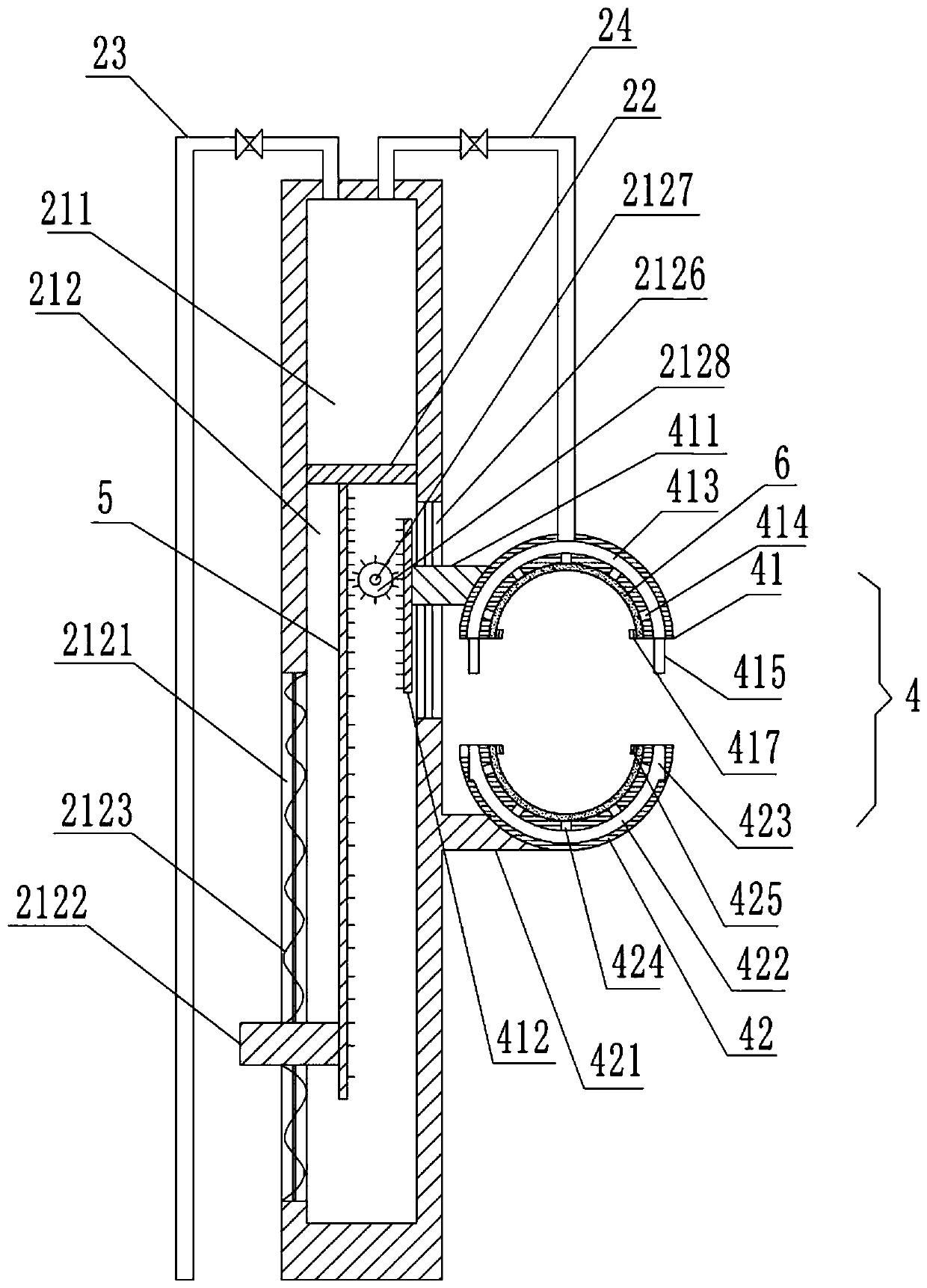

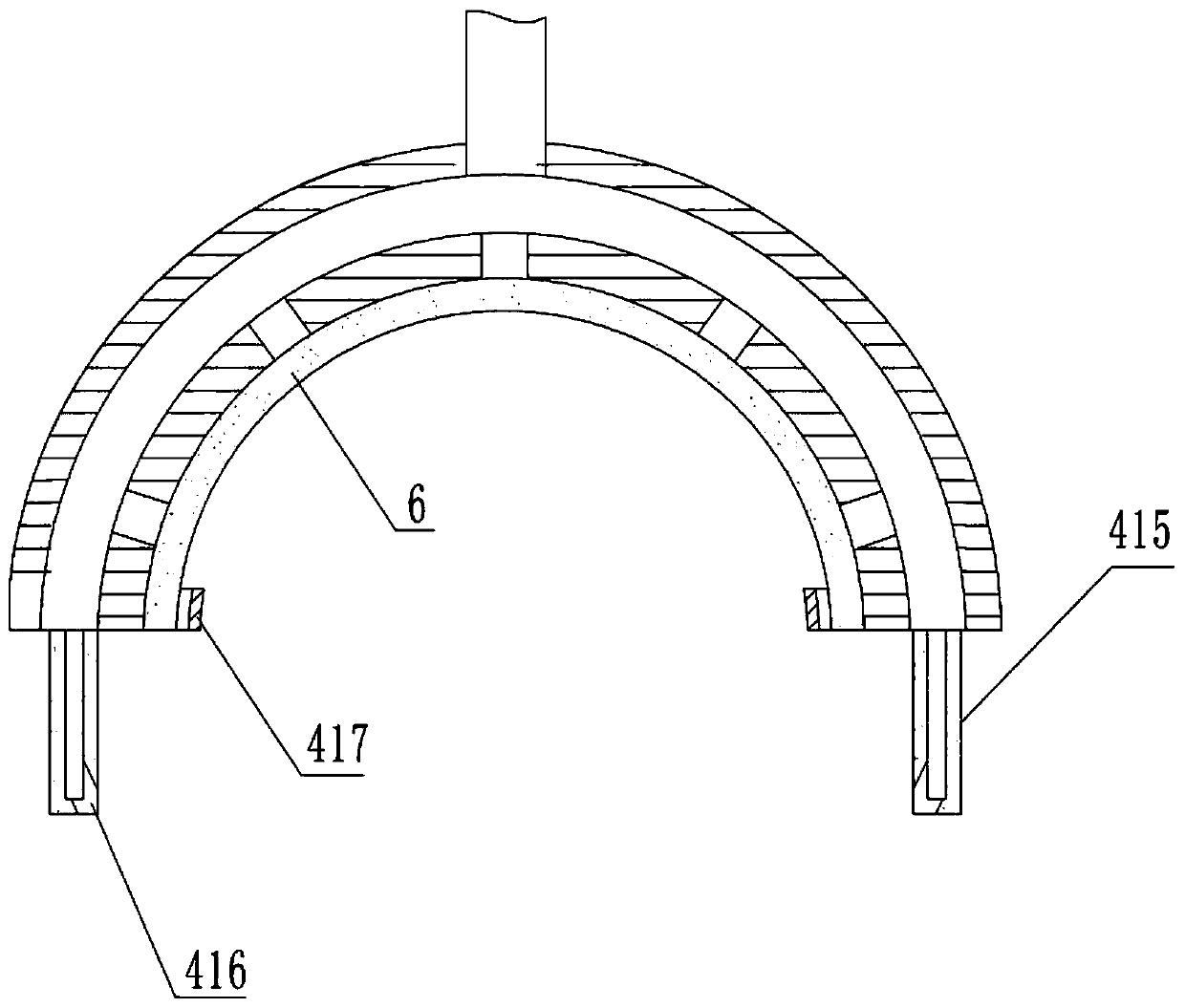

[0028] The reference signs in the drawings of the specification include: car body 1, material cavity 11, feeding channel 12, cover 121, fixed shaft 2, lubrication cavity 211, power cavity 212, strip groove 2121, toggle bar 2122, spring 2123, Positioning hole 2124, screw 2125, sliding groove 2126, rotating shaft 2127, gear 2128, piston 22, feeding telescopic tube 23, discharging telescopic tube 24, hydraulic cylinder 3, clamping part 4, upper clamping ring 41, sliding block 411 , Sliding rack 412, upper cavity 413, through hole 414, drainage rod 415, drainage hole 416, groove 417, lower clamping ring 42, fixed block 421, lower cavity 422, drainage cavity 423, oil supply hole 424, Fixed groove 425, power rack 5, friction layer 6.

[0029] To achieve the above objective, the basic scheme of the present invention is as follows:

[0030] Such as figure 1 , figure 2 with image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com