Nut tightening machine

A technology for tightening machines and nuts, which is applied in metal processing, metal processing equipment, manufacturing tools, etc. It can solve problems such as laborious, slow fastening, and difficult fastening, so as to speed up fastening time, increase productivity, and improve fastening efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

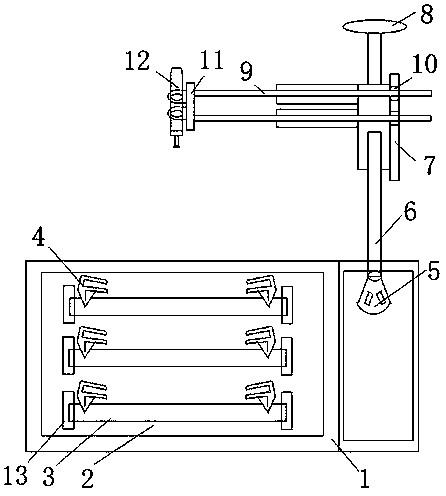

[0011] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0012] A nut tightening machine, which includes a chassis 1, a working panel 2, a chute 3, a sliding clamp 4, a rotating base 5, a lifting rod 6, a fixing plate 7, a handle 8, a connecting rod 9, a buckle 10, and a fixing frame 11 and nut tightener 12, the chassis 1 is a rectangular plate surface, the left side of the surface of the chassis 1 is equipped with a working panel 2 and the right side is equipped with a rotating base 5, the rotating base 5 is connected with the lifting rod 6, and an ellipse is installed on the top of the lifting rod 6 shaped handle 8, the fixed plate 7 is installed in the center of the lifting rod 6, the fixed plate 7 is equipped with buckles 10, the connecting rod 9 is connected with the fixed frame 11, and the connecting rod 9 is inserted through the telescop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com