An oil pipe fastener and method thereof

A technology of fasteners and oil pipes, which is applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of unreliability, labor consumption, reduction of plastic hardness and flexibility, avoid slipping, improve efficiency and reliability, and quickly The effect of tightening and releasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

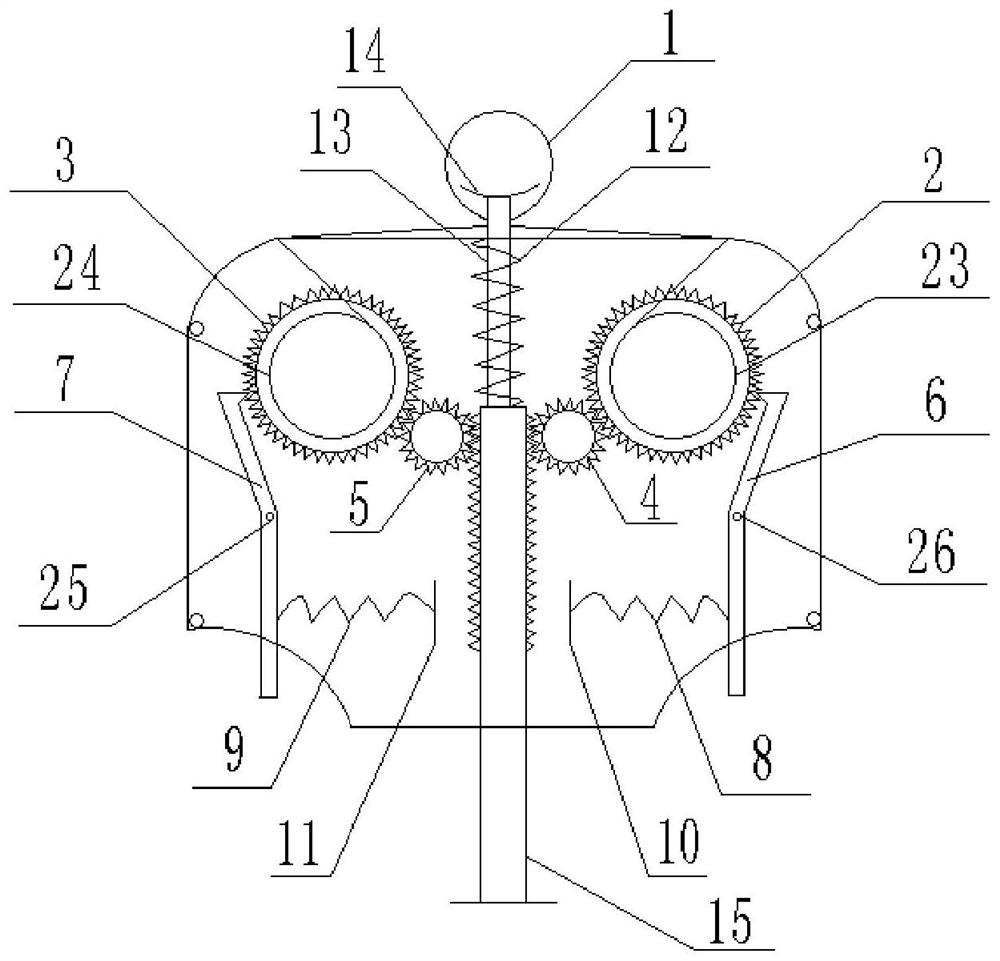

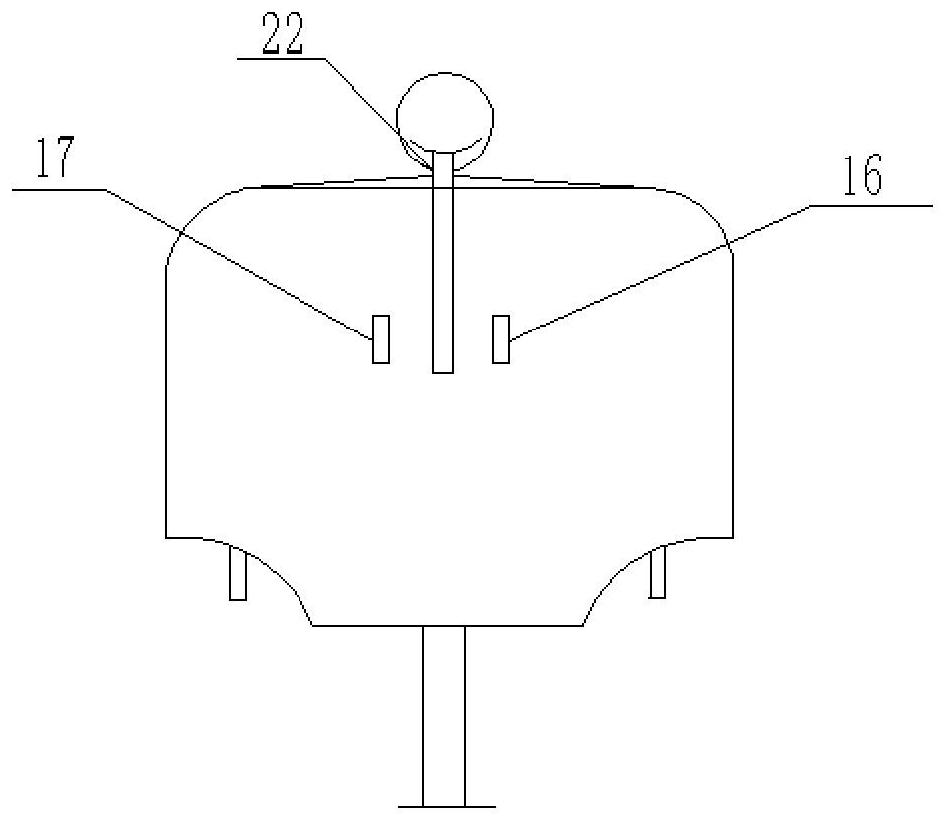

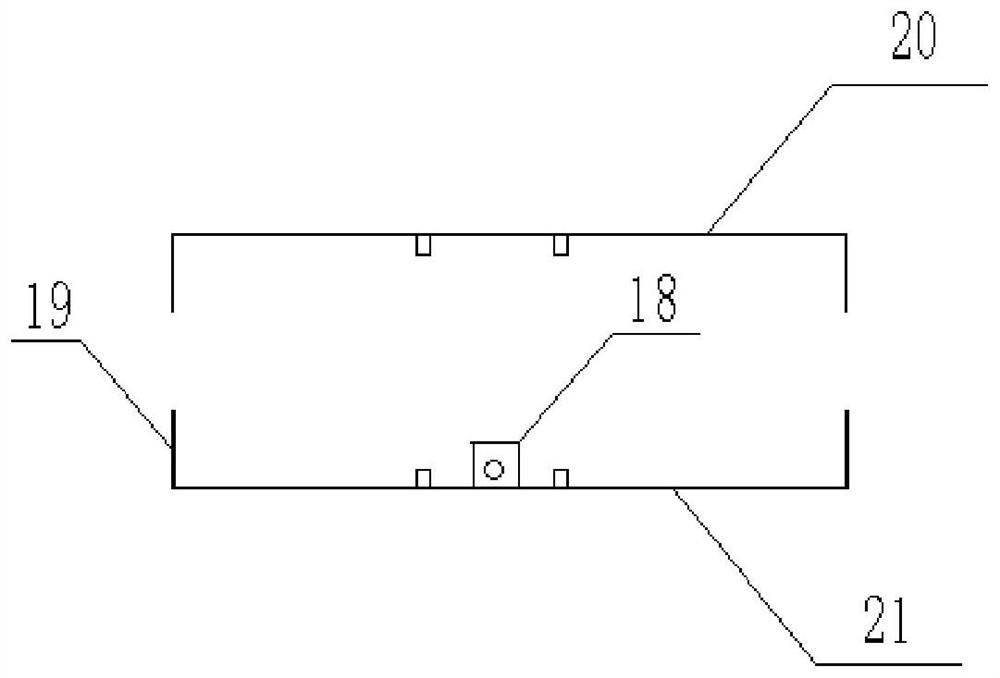

[0049] Such as Figure 1-4 As mentioned above, Embodiment 1 of the present disclosure provides an oil pipe fastener, including a stainless steel wire 1 with a diameter of 0.5 mm, a gear, a toothed push rod 15 and a fastener body, and the toothed push rod 15 is square Plastic push rod, the gears include the first gear 2, the second gear 3, the third gear 4 and the fourth gear 5 arranged inside the fastener body, the first gear 2 is fixed with a first coil 23 , the first gear 2 is fixed with a first reel 23 to rotate coaxially, the second gear 3 is fixed with a second reel 24, and the second gear 3 is fixed with a second reel 24 to rotate coaxially. Both the first gear 2 and the second gear 3 are circular hollow structures, one end of the stainless steel wire 1 is fixedly connected to the first coil 23 through the first through hole on the fastener body, and the other end is passed through the fastening The second through hole on the device body is fixedly connected with the se...

Embodiment 2

[0066] Such as Figure 5 As shown, Embodiment 2 of the present disclosure provides a method for fastening an oil pipe, and the steps are as follows:

[0067] Put the oil pipe into the steel traveler, put the oil pipe on the oil outlet, adjust the fastener steel wire to the proper position of the oil pipe, hold the fastener with your hand, push the toothed push rod, and the first spring is compressed;

[0068] The pushing process of the toothed push rod drives the third gear and the fourth gear to rotate, thereby driving the first gear and the second gear to rotate, and the steel wire is coiled by the first and second coils.

[0069] After the toothed push rod is fully pressed, release the toothed push rod, the first spring rebounds from the compression, driving the toothed push rod to reset, the third gear and the fourth gear slide along the first slide rail and the second slide rail respectively , separated from the first gear and the third gear, the toothed push rod is rese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com