SMA-Wire-actuated (shape memory alloy wire-actuated) ultrahigh-load unlocking device

A technology of super large load and unlocking device, which is applied in the docking device of aerospace vehicles, motor vehicles, transportation and packaging, etc. It can solve the problems of inability to release super large loads, poor anti-vibration and shock performance without redundant design, and achieve Prevents heat loss, shortens heating and deformation time, and releases large loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings.

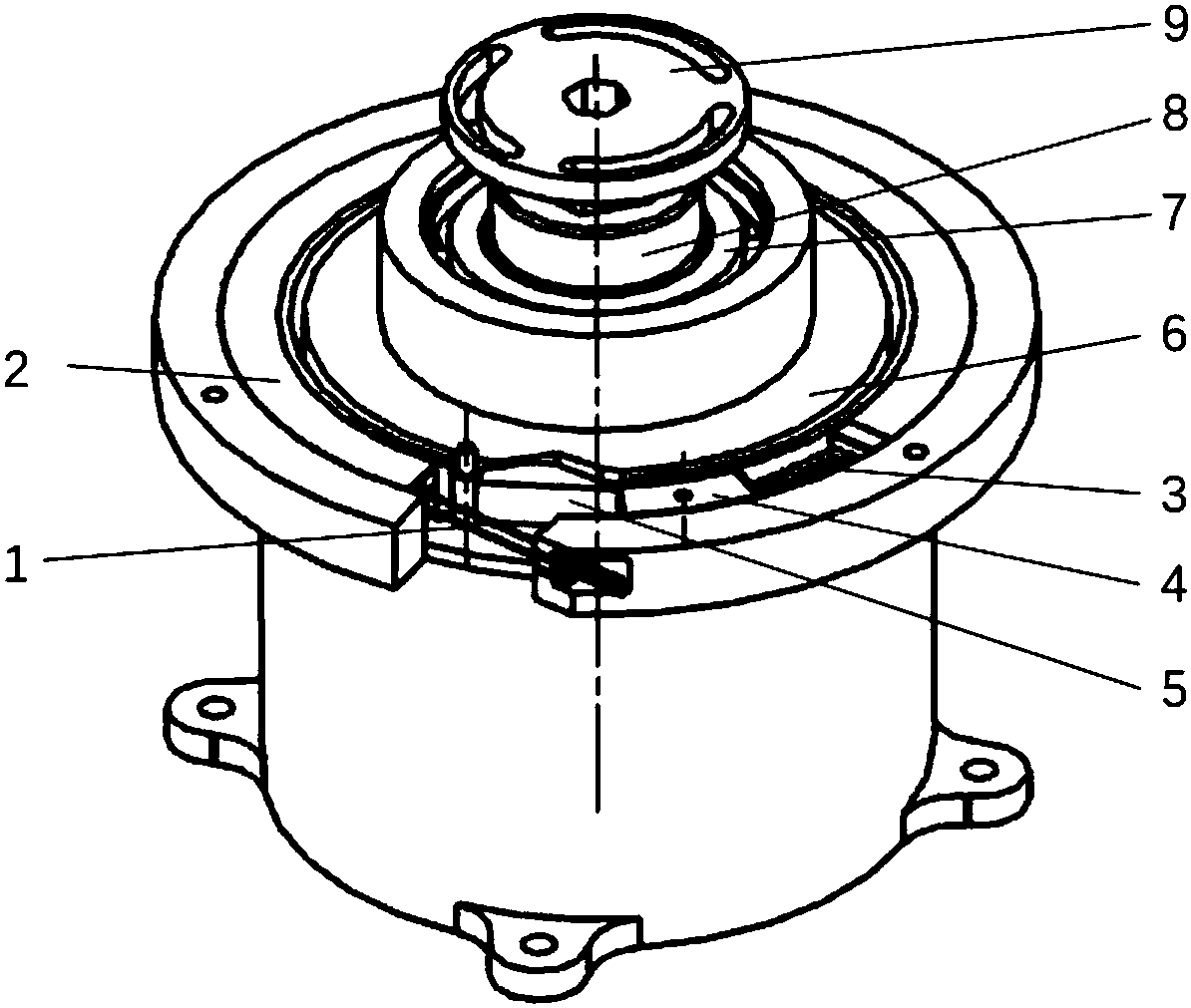

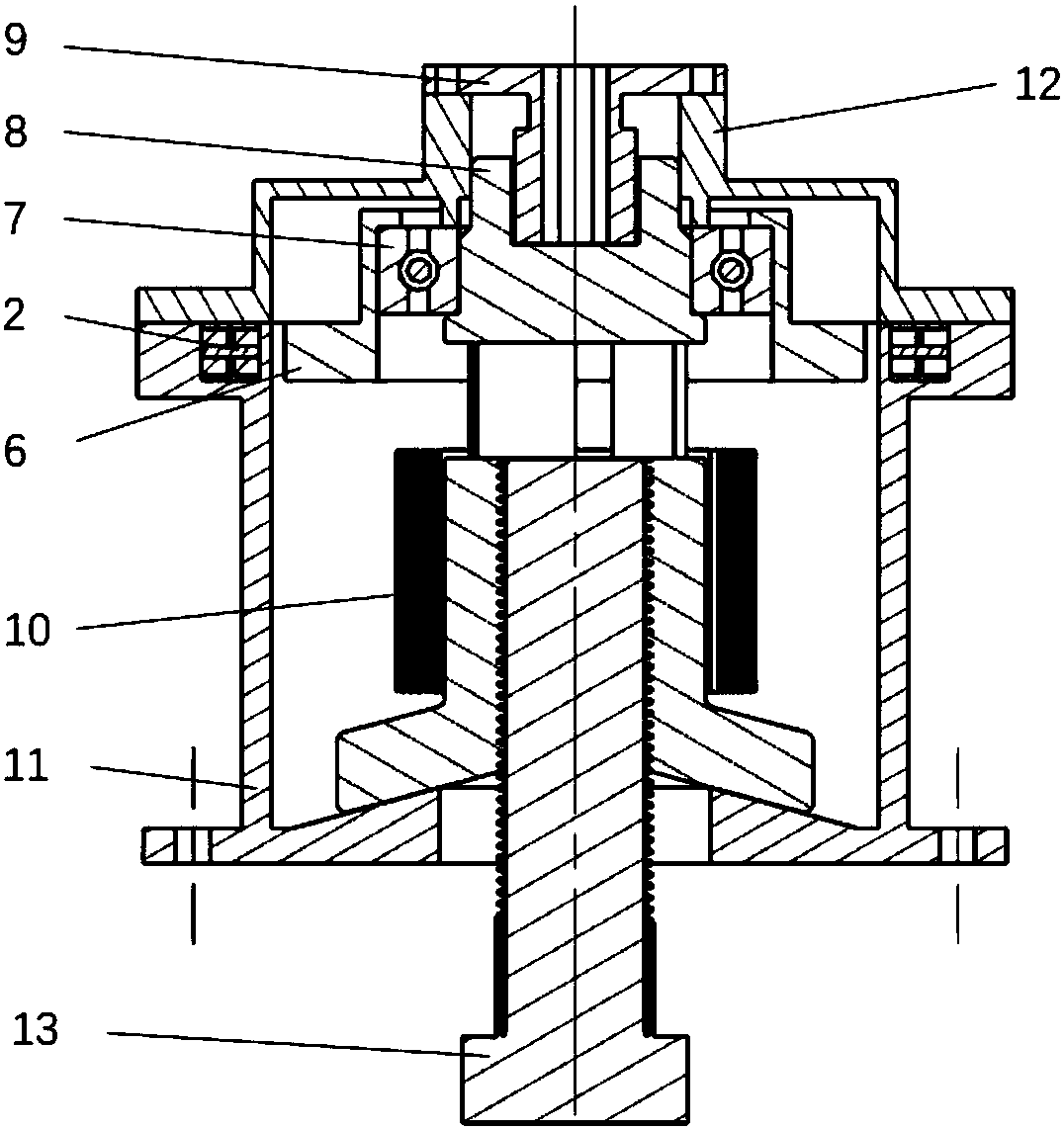

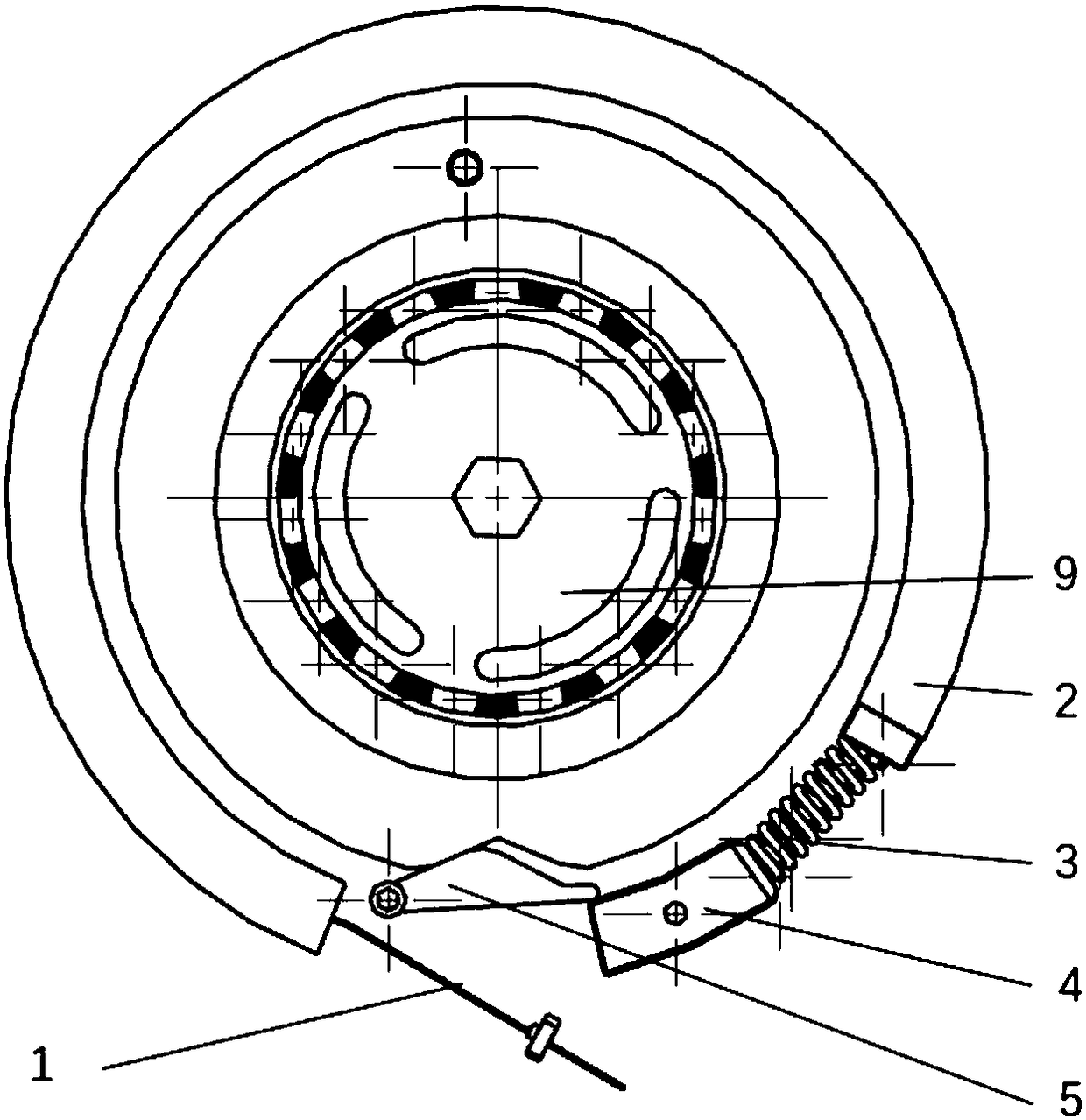

[0041] The invention provides an SMA wire-driven super-large load unlocking device, the structure of which is as follows: Figure 1 ~ Figure 3 shown. The lower cover 11 is connected to the fixed structure, the large bolt 13 is connected to the separation structure, the large bolt 13 and the split nut 8 are connected by a thread pair, and the split nut 8 locks the large bolt 13 under the wrapping of the scroll spring 10, thereby realizing Connection function; the inner end of the scroll spring 10 is fixed on the split nut 8, and the outer end is connected with the frame 6 through a pin, and the split nut 8 and the frame 6 cooperate with the inner ring and the outer ring of the bearing 7 respectively; The head is fixed on the upper cover 12, and the lower part is inserted into the hexagonal hole on the top surface of the split nut 8; one end of the SMA wire 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com