Spinning machine crank inspection tool

A crank and spinning machine technology, applied in the direction of angle/taper measurement, etc., can solve the problems of large detection error, different crank 1001, and long time measurement, etc., and achieve the effect of convenient use, simple detection and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

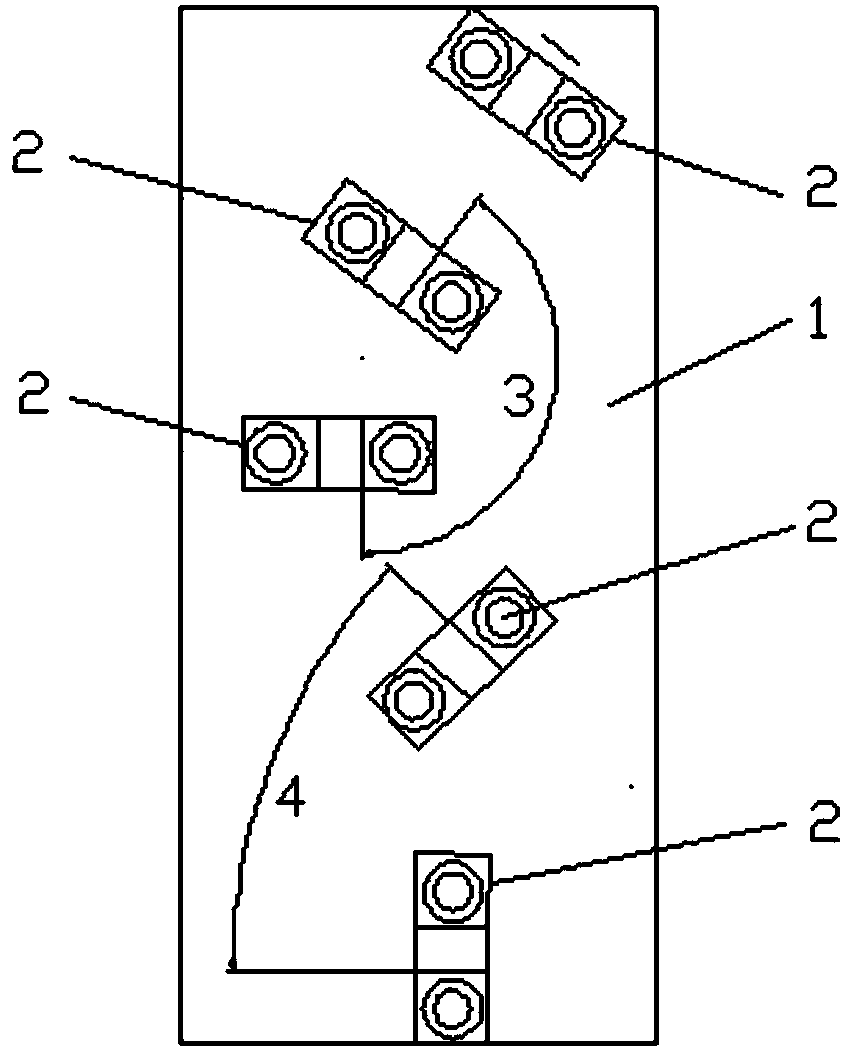

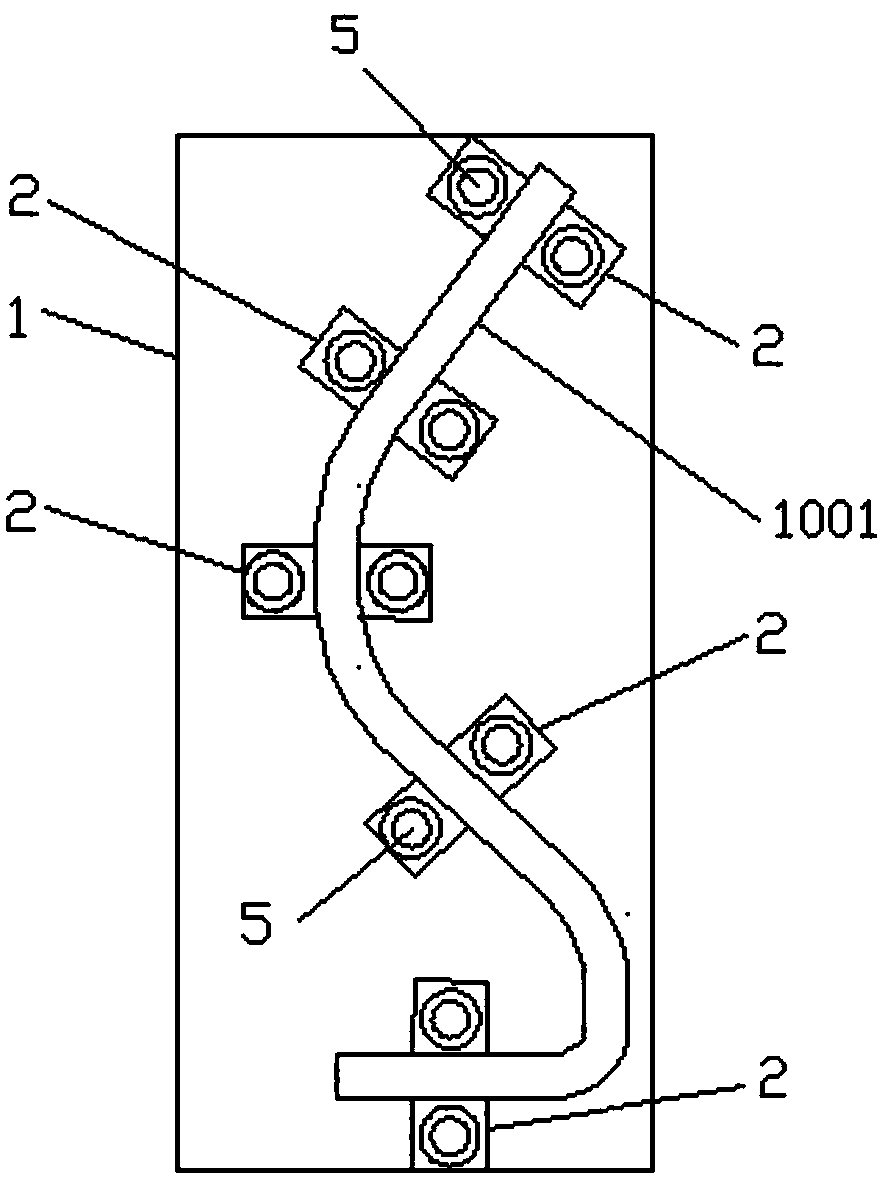

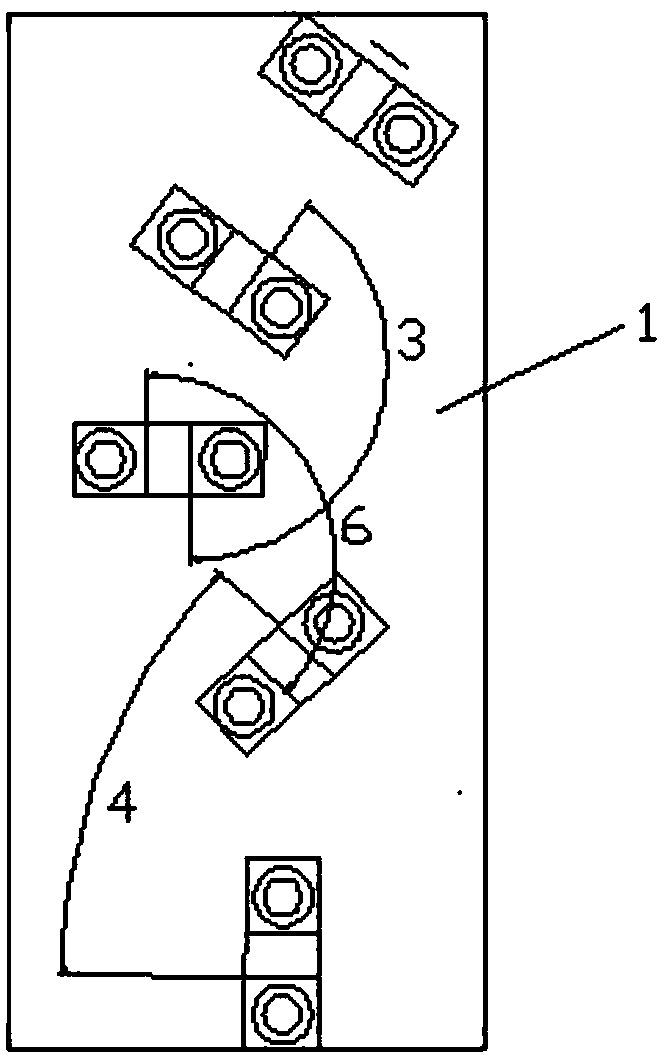

[0015] like Figure 1 to Figure 5 As shown, the textile machine crank inspection tool includes a flat plate 1, a deck 2, and a fixing screw 5. The flat plate 1 is provided with several decks 2 from top to bottom, and a slot 201 is arranged in the middle of the deck 2. A through hole 202 is provided on the side, and a counterbore 203 is provided at the upper end of the through hole 202. The fixing screw 5 penetrates through the through hole 202 and the counterbore 203 is connected with the screw hole of the plate 1. Each slot of the present invention is distributed with the crank bending technology. The same angle is required. When the crank is bent, as long as the relevant parts of the crank are put into the slot, it will be detected that the bending of the crank meets the technical requirements. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com