High-rotating-speed type spiral oil press

An oil press, high-speed technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of increasing the output per hour, unable to increase the speed of rotation, etc., and achieve the effects of simple structure, improved oil yield, and increased oil yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below with reference to the accompanying drawings in combination with specific embodiments. Those skilled in the art understand that this description is exemplary, and the present invention is not limited to this specific implementation.

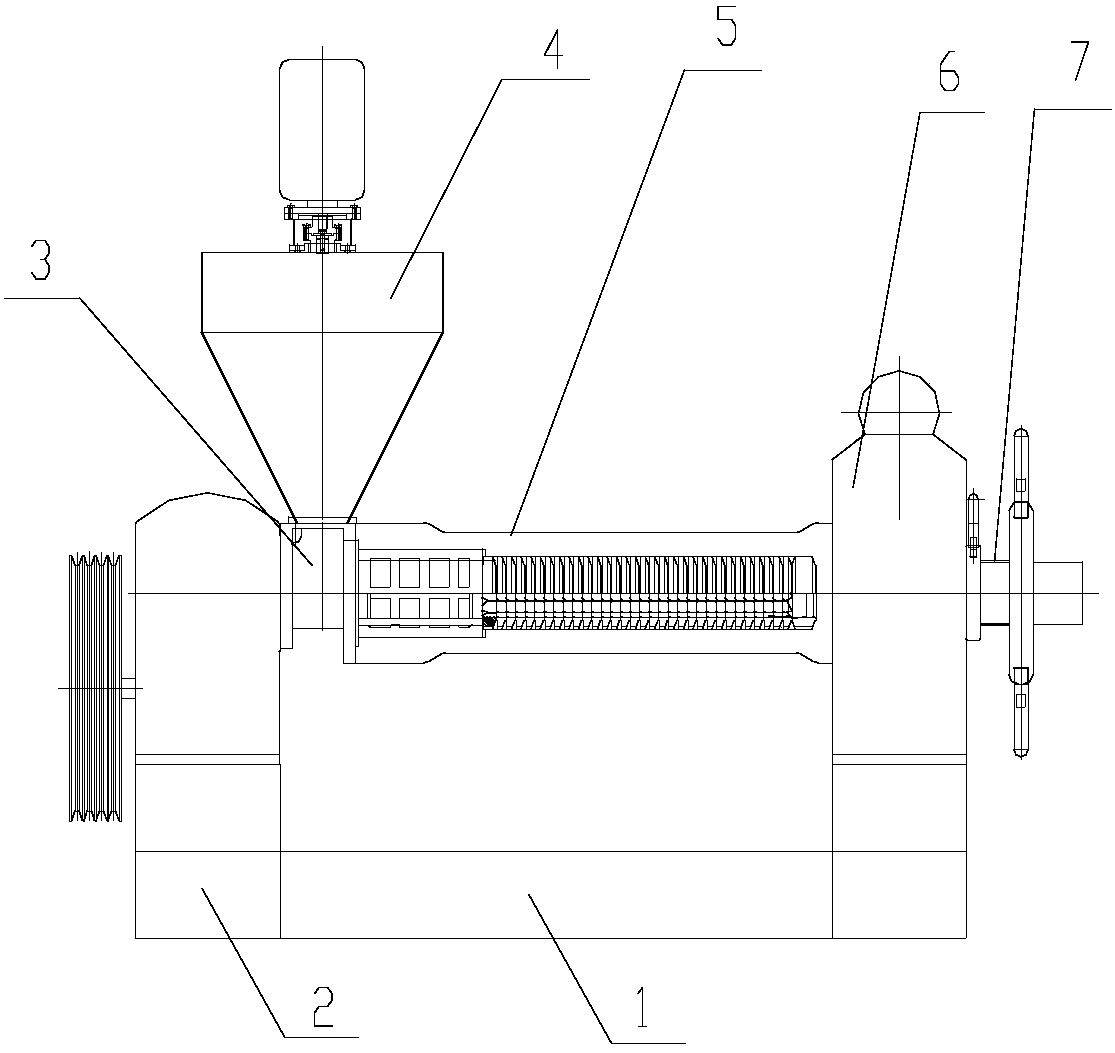

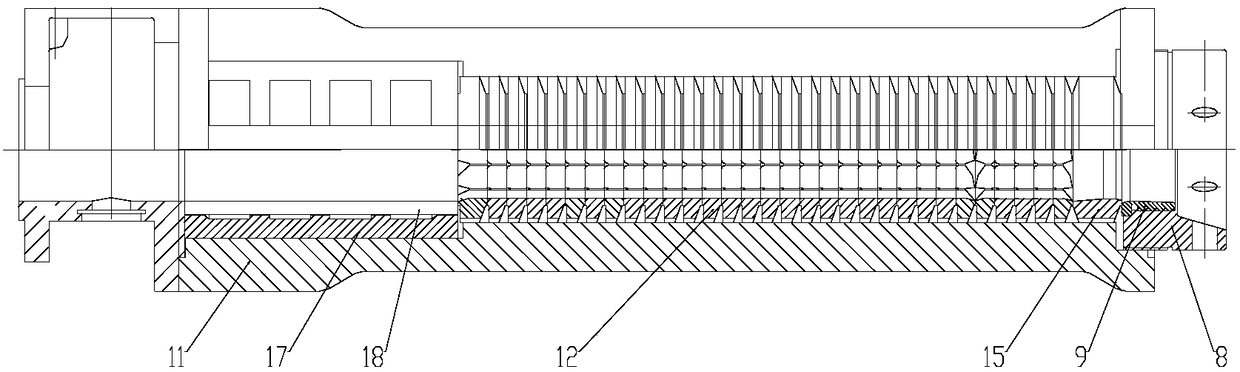

[0035] figure 1 It is a schematic structural diagram of a high-speed screw oil press involved in a specific embodiment of the present invention;

[0036] Such as figure 1As shown, the high-speed screw oil press includes a bottom plate 1, a gear box assembly 2 and a frame 6 are respectively installed on the left and right ends of the bottom plate 1, and the right side of the gear box assembly 2 is connected to the feed nozzle 3, and the feed nozzle Hopper assembly 4 is installed above 3, the right end of feed nozzle 3 is connected to squeeze cage assembly 5, and the right end of squeeze cage assembly 5 is connected to frame 6, and frame 6, squeeze cage assembly 5 and gear box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com