A petrochemical factory inspection robot positioning system and method

A technology of inspection robot and positioning method, which is applied in the direction of satellite radio beacon positioning system, radio wave measurement system, instrument, etc., to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

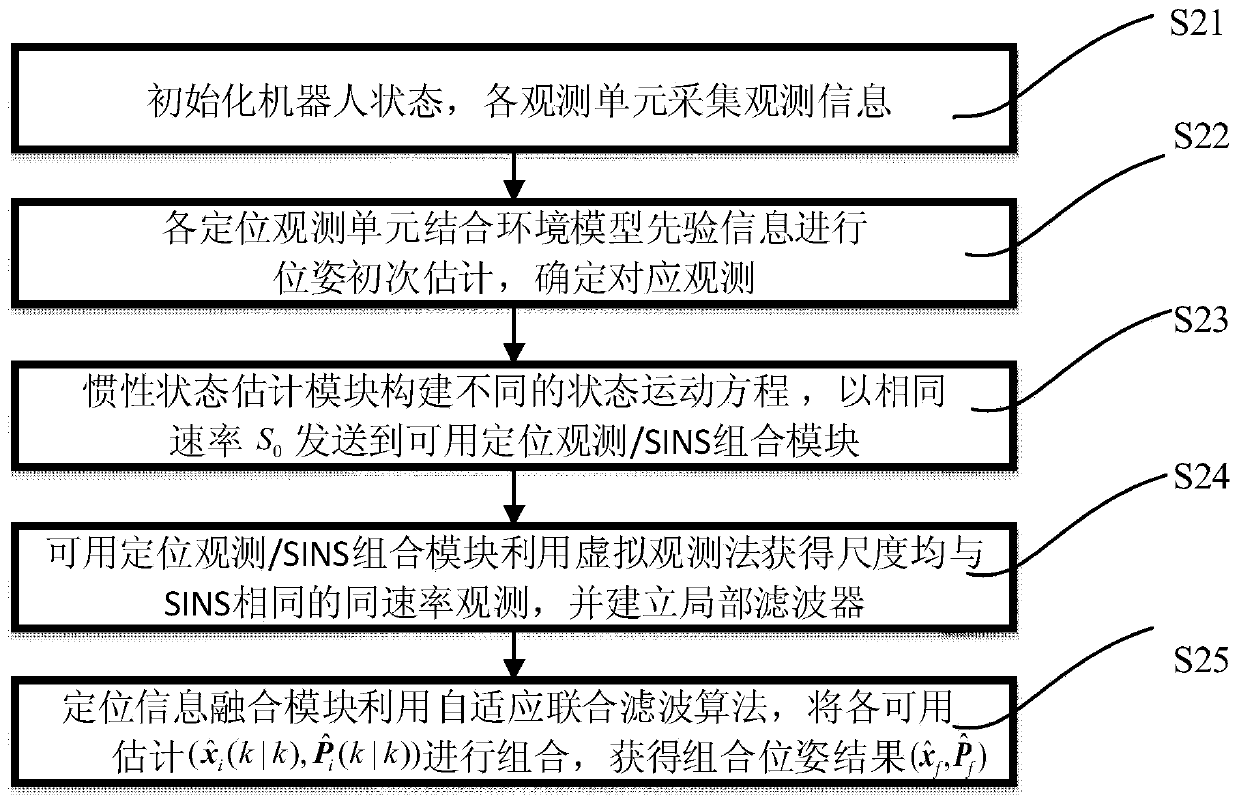

[0049] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

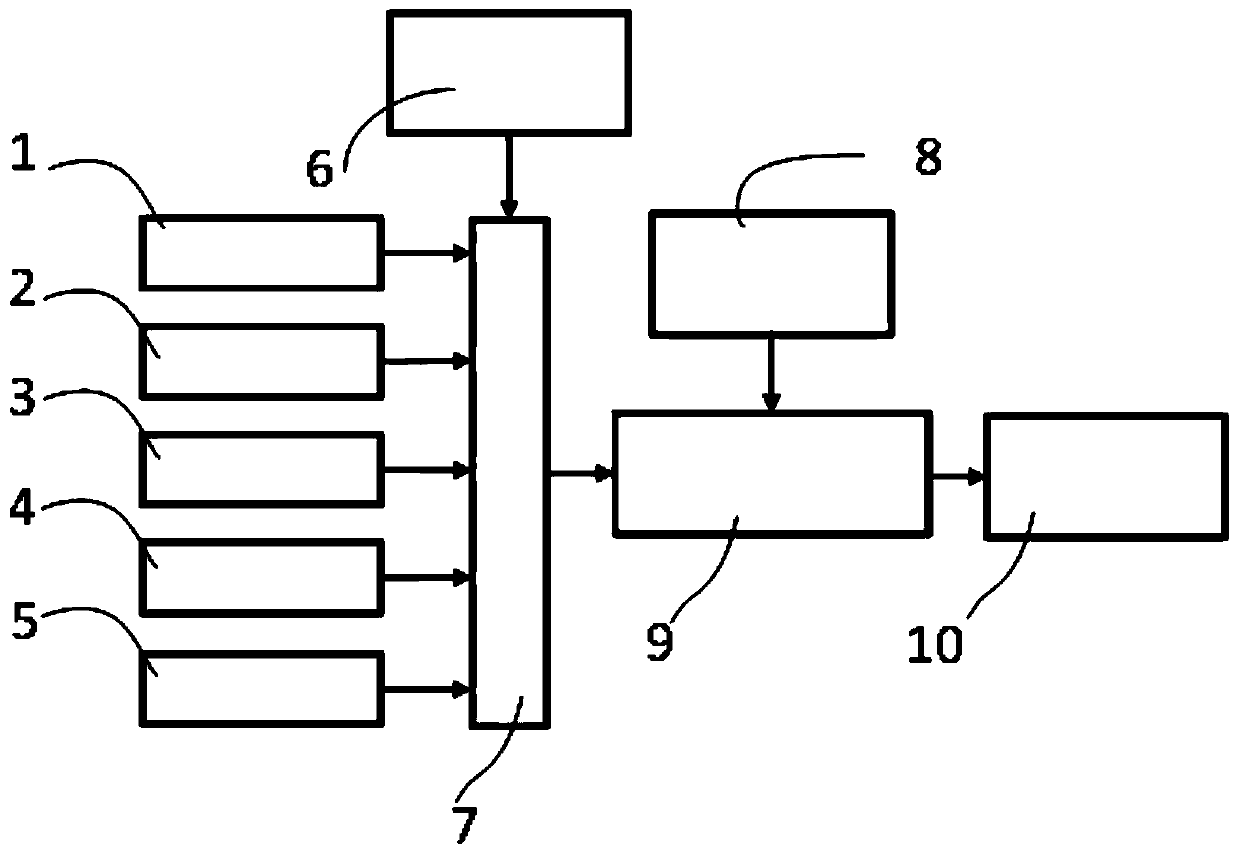

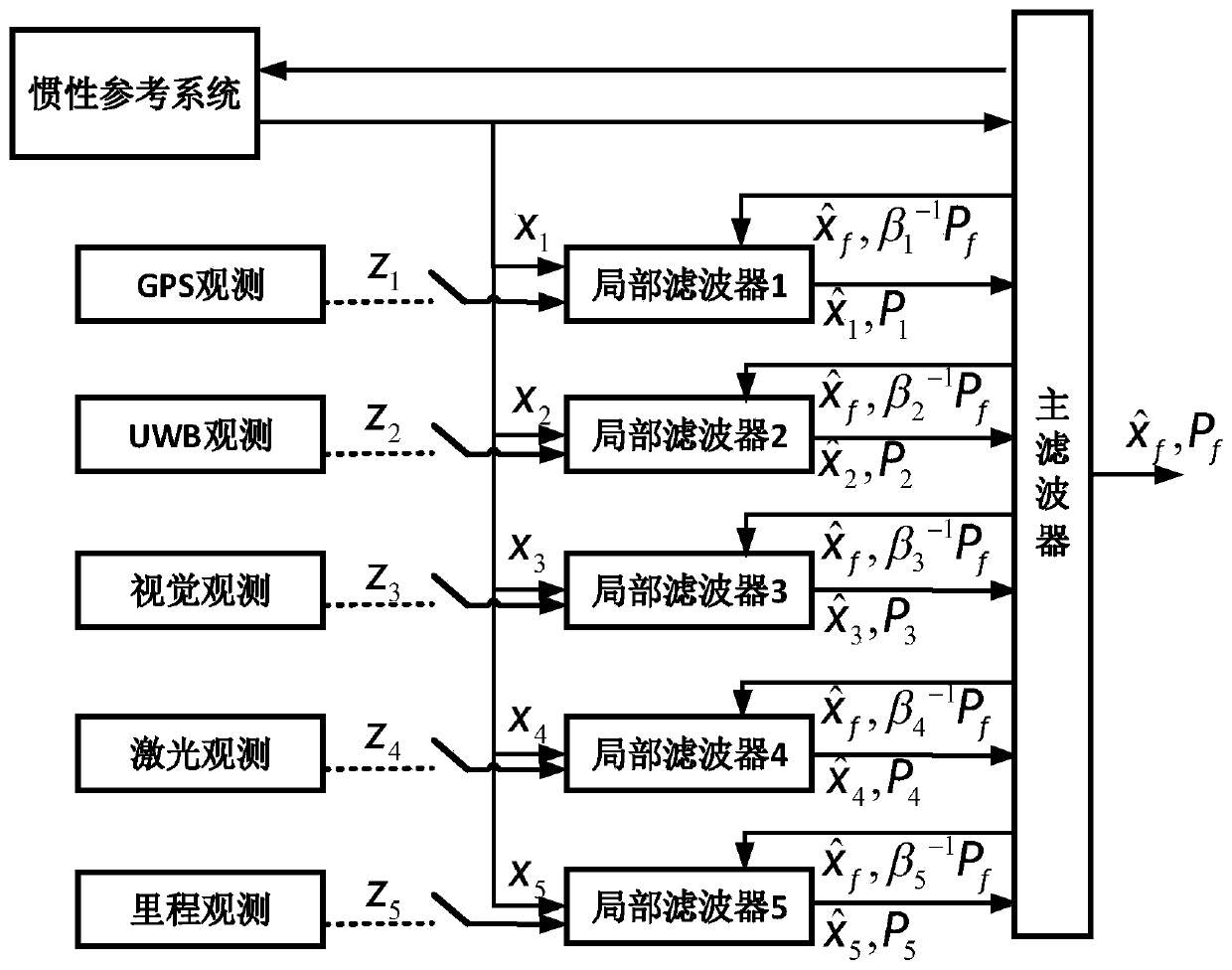

[0050] Such as figure 1 As shown, the petrochemical plant inspection robot positioning system designed by the present invention includes a GPS observation unit 1, a UWB observation unit 2, a visual observation unit 3, a laser observation unit 4, a mileage observation unit 5, an environment model prior information module 6, a combination Decision-making module 7 , inertial state estimation module 8 , available positioning observation / SINS combination module 9 and positioning information fusion module 10 .

[0051] The combined decision-making module 7 receives the environmental map model stored in the environmental model prior information module 6, combines each observation data to perform positioning based on the multi-layer map, judges the available observation type, and sends the available observation data to the available positioning ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com