Crane span structure with multiple slots

A bridge and wire trough technology, applied in the field of fire bridges, can solve problems such as confusion and great harm, and achieve the effect of easy management, easy discharge, and possibility of reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

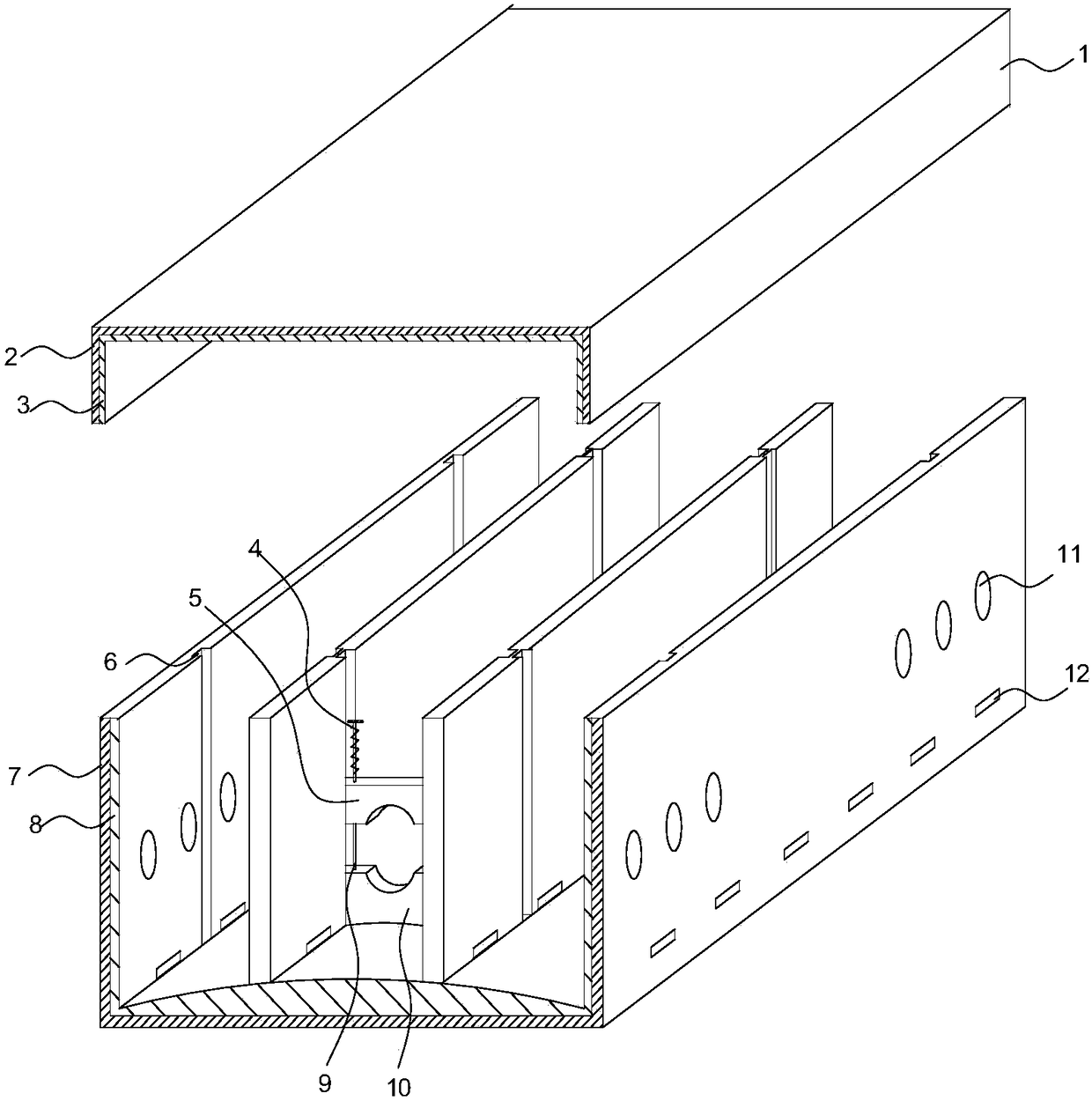

[0018] like figure 1 As shown, the present invention provides a fireproof bridge with multi-wire slots, including a cover and a slot, the cover and the slot are used in conjunction, and the cover is closed on the slot, and the wall of the cover and the slot The walls of the body all include an outer metal layer and an inner fire-proof and heat-insulating layer. The inside of the tank is divided into three sub-slots by fire-proof and heat-insulated panels arranged parallel to the side walls. There are sliding grooves corresponding to the positions, the lower end of the sliding groove is fixed or non-fixedly provided with a lower support block, and an upper pressing block used in conjunction with it is arranged above it, and the two ends of the upper pressing block are respectively slidingly connected with the sliding groove, The upper pressing block and the lower supporting block are respectively provided with symmetrically arranged arc-shaped grooves, and the cables pass throu...

Embodiment 2

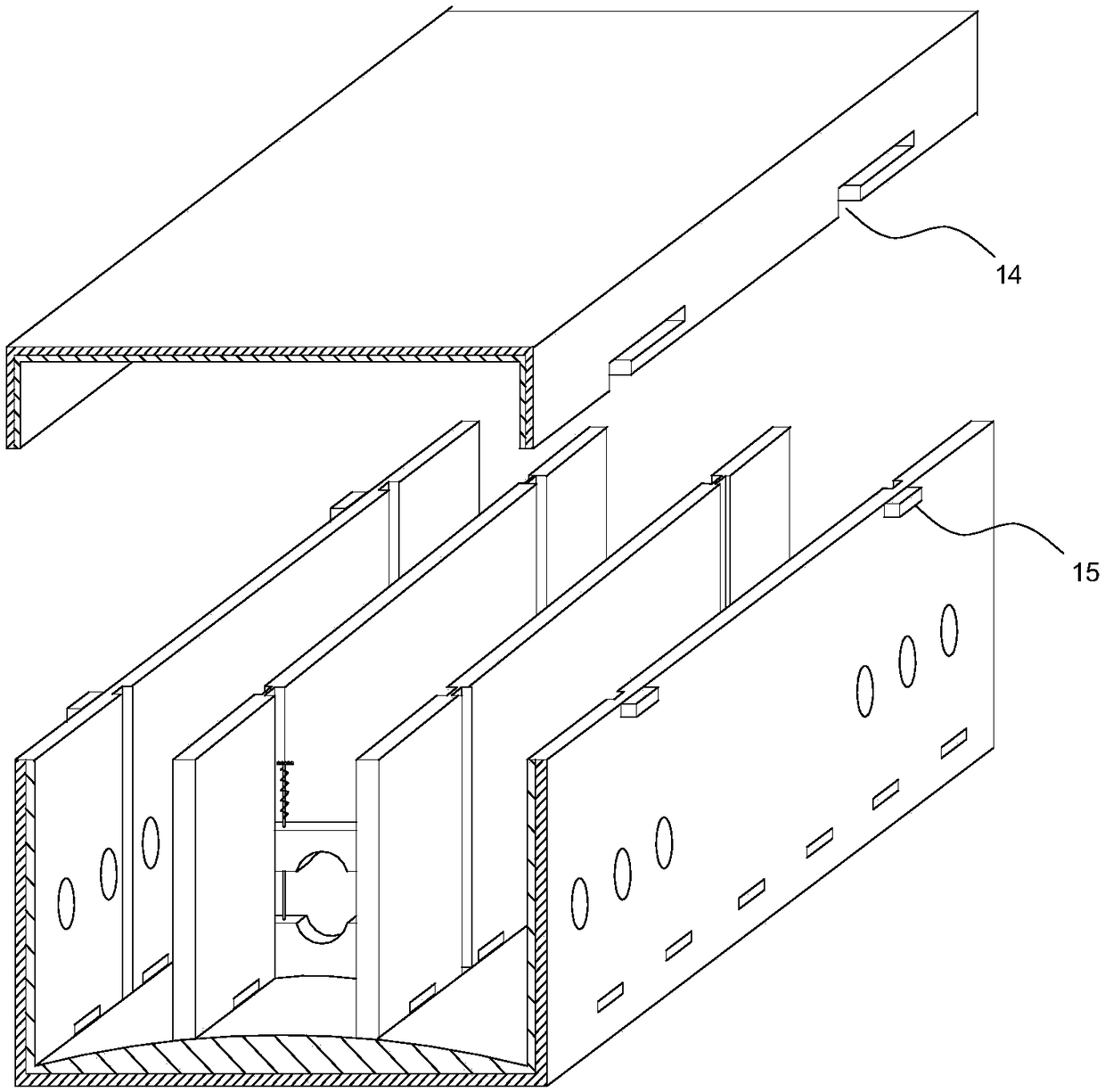

[0025] like Figure 3-Figure 4 As shown, an improvement is made on the basis of Embodiment 1, and a connection structure between the cover and the tank is provided. The two sides of the cover are provided with card slots, and the slots at the corresponding positions are all A clamping block is provided, the clamping block is a square block, the clamping groove is an L-shaped groove, the width of the clamping block is consistent with the width of the longitudinal groove of the L-shaped groove, and the height of the clamping block is the same as that of the L-shaped groove. The height of the transverse grooves is uniform.

[0026] Utilizing the above structure, when the cover body is closed on the tank body, the part of the longitudinal groove of the L-shaped groove corresponds to the block, and moves downward, so that the block enters the L-shaped groove, and after moving in place, When the cover is pushed forward, the locking block is locked in the transverse groove of the L-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com