Electric welding device

A welding device and electric welding machine technology, which is applied to welding accessories and other directions, can solve the problems of power supply line damage, inconvenient power supply line retraction, induced electric shock, etc., to prevent electric shock accidents, reduce manual cable collection, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

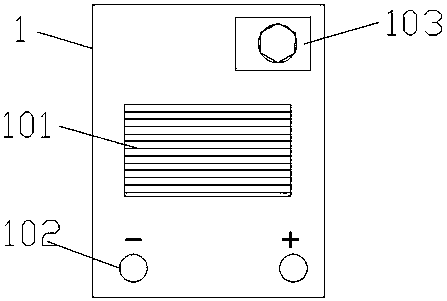

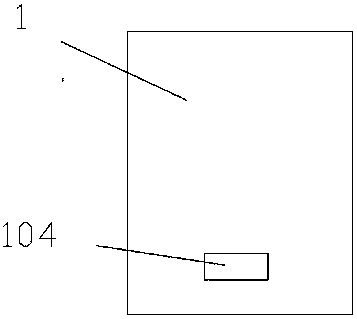

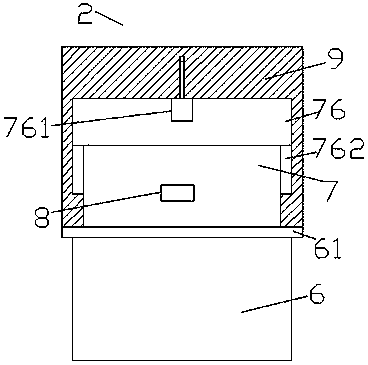

[0025] Such as Figure 1-Figure 9 As shown, an electric welding device of the present invention includes an electric welding machine 1 and a connecting piece 2, and the connecting piece 2 consists of a vertical pole 6, a container 7 fixed on the top of the vertical pole 6, and a 7 top outer casing 9 is combined, a first cavity 71 is provided in the container 7, a second cavity 72 is provided in the container 7 on the right side of the first cavity 71, the The first sliding cavity 73 is provided in the container 7 above the left side of the first cavity 71, and the second sliding cavity 74 is provided in the container 7 below the second cavity 72. The cavity 71 is provided with a rotating shaft 710 extending to the left and right sides. The extended section on the right side of the rotating shaft 710 penetrates the inner wall of the container 7 and penetrates into the second cavity 72 and is connected in operation. The rotating shaft 710 in the first cavity 71 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com