A container cleaning device

A technology for cleaning equipment and containers, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low cleaning efficiency, labor-intensive, and difficulty in cleaning the inner wall of containers, and achieve convenient operation and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

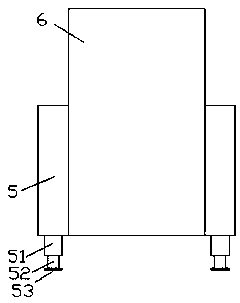

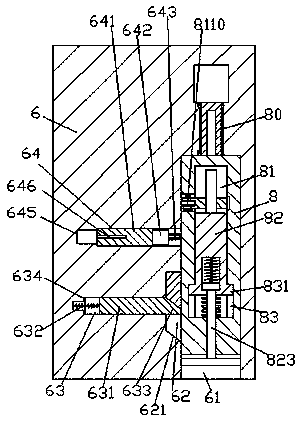

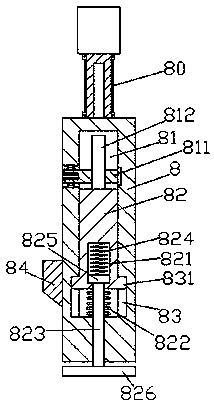

[0016] Such as Figure 1-Figure 4 As shown, a container cleaning device of the present invention includes a housing 6 fixedly installed in the main frame 5, a supporting column 51 is fixedly installed on the outer periphery of the bottom end surface of the main frame 5, and the bottom of the supporting column 51 is movable and equipped with up and down movement Rod 52, the base 53 is fixedly installed at the bottom of the up-and-down adjusting rod 52, and a sliding groove 61 is provided on the bottom end surface of the housing 6 to expand upwards, and a sliding frame 8 is smoothly fitted and connected in the sliding groove 61, A fitting groove 62 is provided in the inner wall on the left side of the sliding groove 61, and a fitting block 84 is smoothly fitted and connected with the outer wall body on the left side of the sliding frame 8 in a smooth fit. A hydraulic cylinder member 80 fixedly mounted on the inner top wall of the sliding groove 61 is fixedly connected with the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com