Adjustable horse stool system and use method thereof

An adjustable stirrup technology, applied in building maintenance, pillars, on-site preparation of building components, etc., can solve problems such as reducing the reuse rate and service life of horse stools, the height of stirrups cannot be adjusted, and affecting on-site construction operations. Improve the reuse rate, avoid welding to lengthen or truncate the corner posts of the horse bench, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

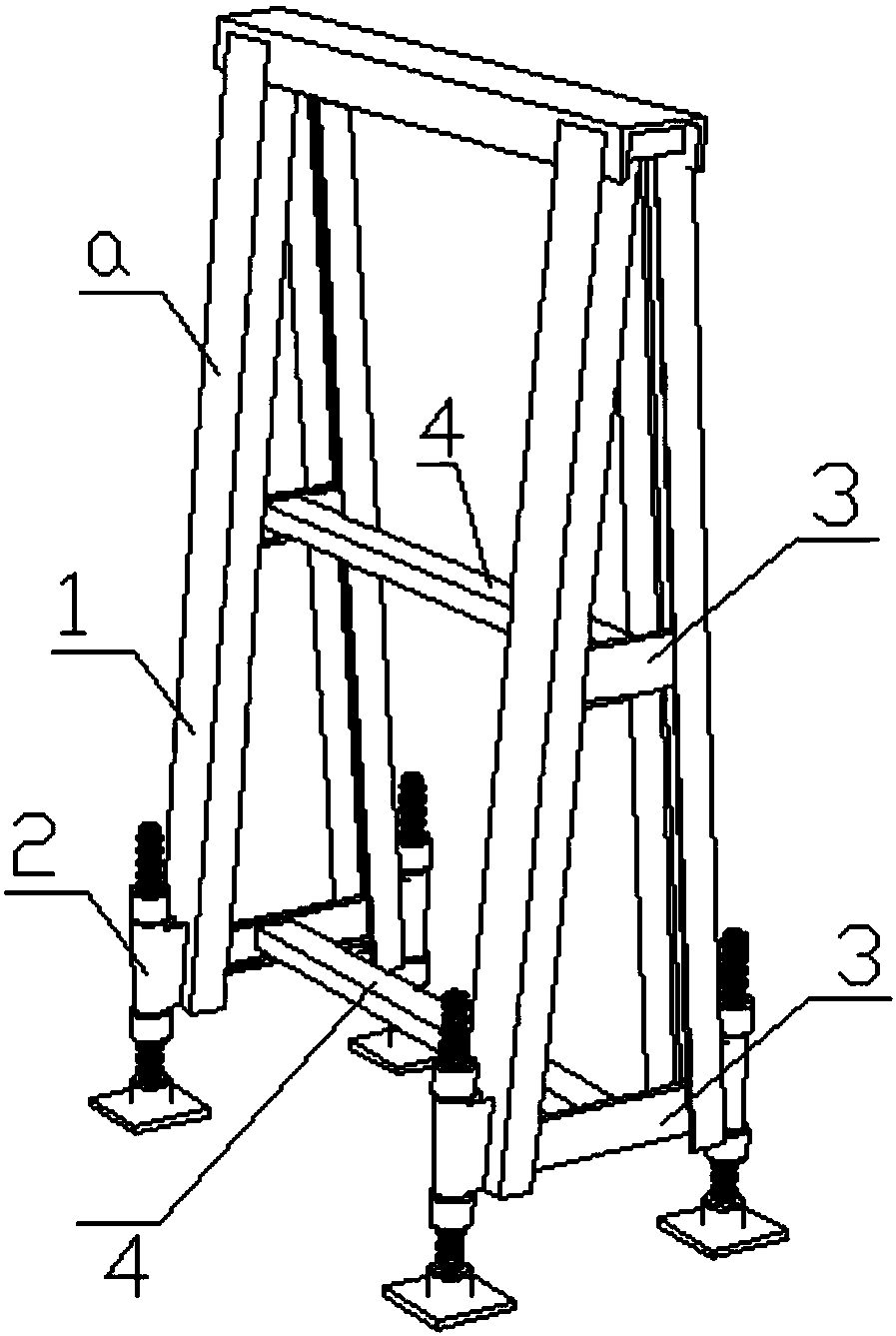

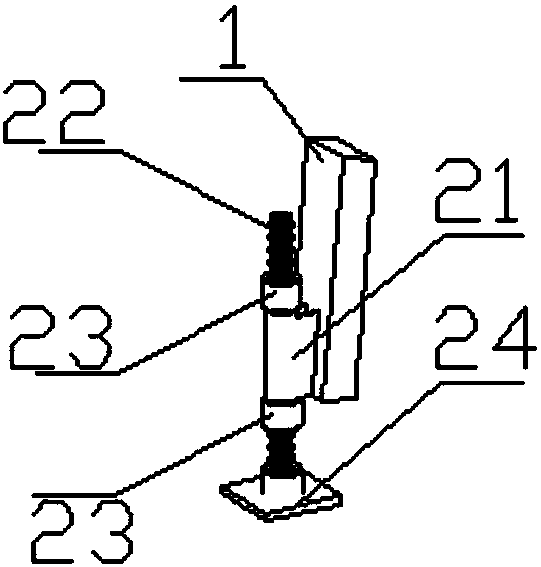

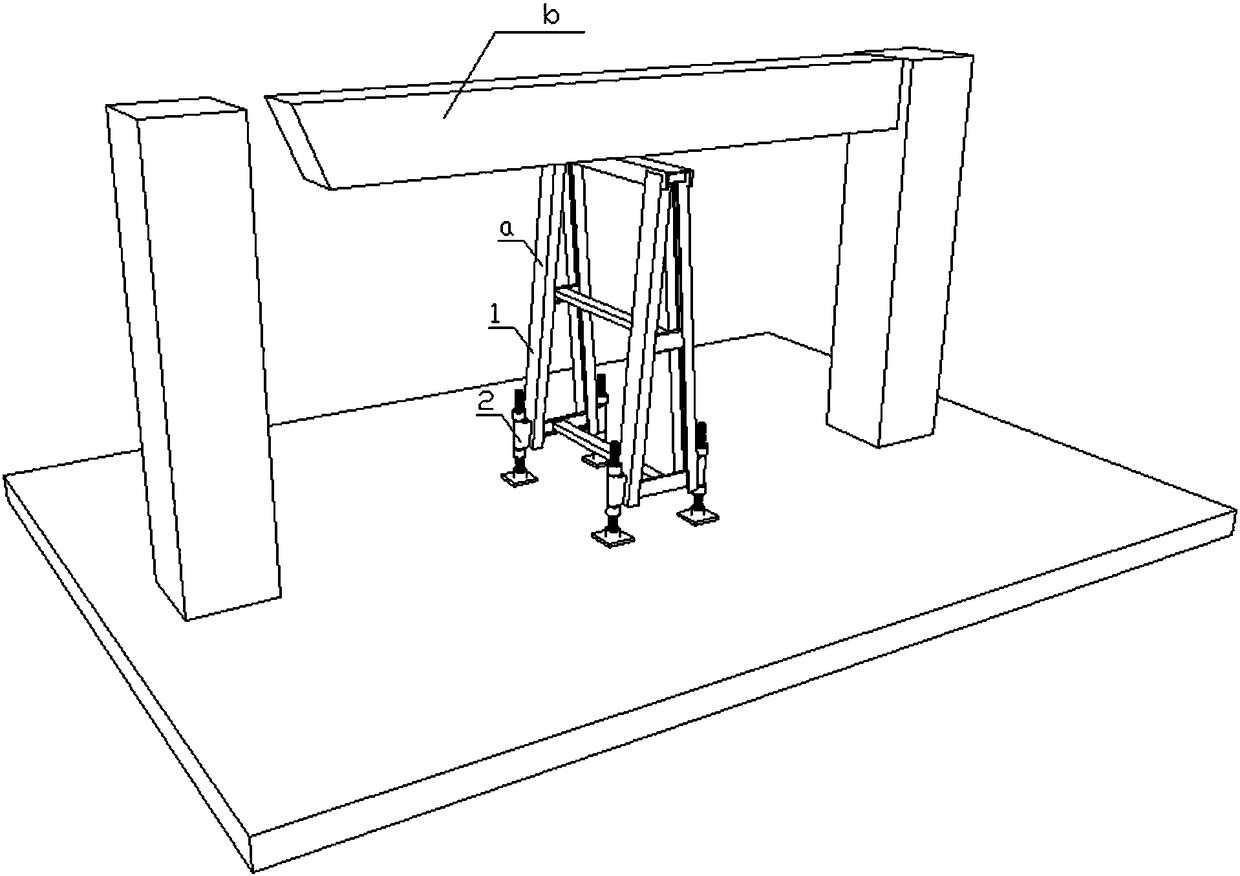

[0026] refer to Figure 1 to Figure 3 , the present embodiment provides an adjustable stirrup system, including a stool frame body a with several support columns 1 at the bottom, and adjustment devices 2 , and the adjustment devices 2 are respectively provided at the bottom ends of the support columns 1 .

[0027] An adjustable stirrup system in this embodiment is suitable for supporting components b to be removed at different heights from the ground. By adjusting the adjustment device 2 at the bottom of each support column 1, the horse stool frame body a can be raised or lowered as required, thereby solving the problem that the height of the existing horse stool cannot be adjusted, and avoiding the need for on-site welding to lengthen or cut off the horse stool The corner post improves the reuse rate of the horse stool and prolongs the service life of the horse stool.

[0028] As a preferred embodiment, in the adjustable stirrup system of this embodiment, specifically, the a...

Embodiment 2

[0032] This embodiment provides a method for using the adjustable stirrup system described in Embodiment 1.

[0033] The technical solution of a method of using an adjustable stirrup system in this embodiment is as follows, including the following steps:

[0034] In the first step, the adjustable stirrup system is placed under the component b to be removed, leaving a gap between the adjustable stirrup system and the component b to be removed;

[0035] The second step is to adjust the adjustment device 2 at the bottom end of each support column 1, so that the upper part of the adjustable stirrup system is connected to the member b to be removed;

[0036] The third step is to lock the adjustment device 2 to ensure that the adjustable stirrup system is stable and firm.

[0037] The use method of the adjustable stirrup system in this embodiment is suitable for supporting components b to be dismantled at different heights from the ground. By adjusting the adjustment device 2 at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com