Heat-pump water heater and control method thereof

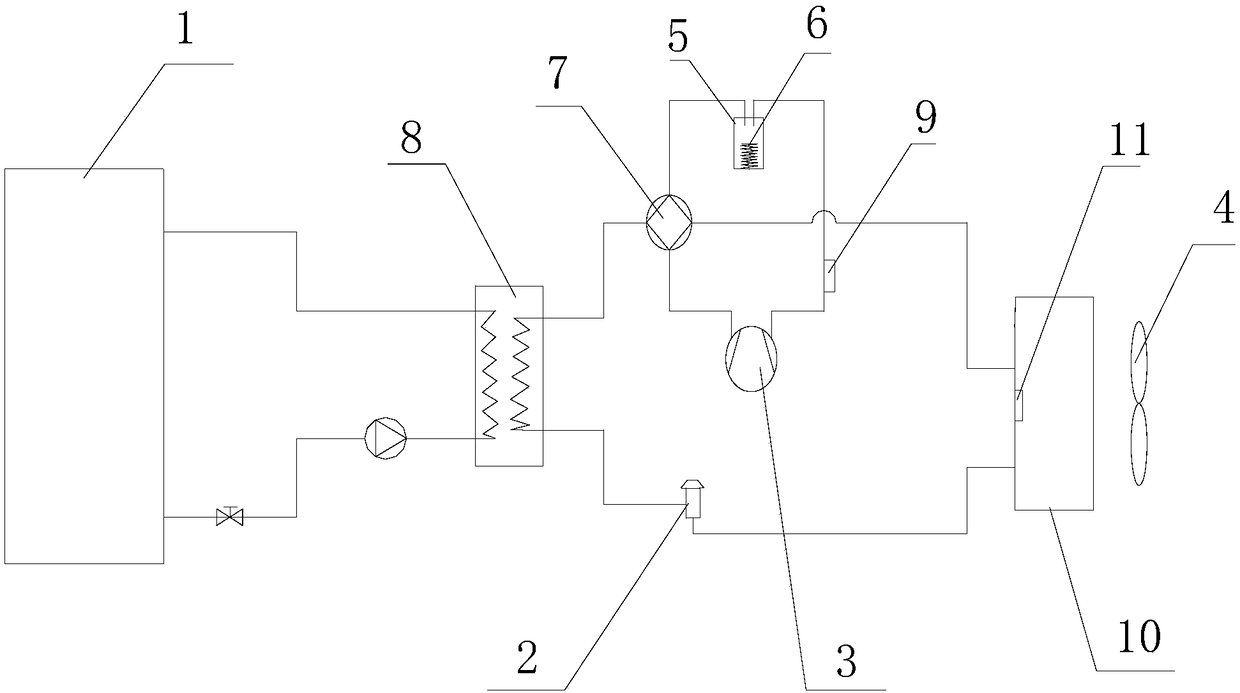

A technology of heat pump water heater and control method, applied in the directions of fluid heater, lighting and heating equipment, etc., can solve the problems of liquid hammer, liquid refrigerant entering gas-liquid separator, affecting the service life of compressor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment provides a control method for a heat pump water heater, which includes obtaining the steam temperature at the inlet end of the compressor, and judging whether the gas-liquid separator meets the conditions for vaporizing the cold medium. If not, the heating device heats the gas-liquid separator to reach the cold medium vaporization conditions.

[0055] Wherein, the condition for determining whether the gas-liquid separator reaches medium vaporization is:

[0056] Judging whether the suction superheat degree of the compressor reaches the target suction superheat degree, if the judgment result is yes, then the gas-liquid separator meets the condition of cold medium vaporization, if the judgment result is no, then the gas-liquid separator does not meet the condition of medium vaporization . Wherein, the compressor target suction superheat degree is the corresponding compressor suction superheat degree when the gas-liquid separator can reach the vaporization...

Embodiment 2

[0066] In the second embodiment, the heating device includes an electric heater with adjustable power, and the controller determines the output power of the electric heater according to the suction superheat of the compressor. When the suction superheat of the compressor increases, the electric heater is reduced. output power of the heater.

[0067] Further, the compressor suction superheat degree is set to a plurality of suction superheat degree gears, and the electric heater has a plurality of corresponding heating power gears, wherein the compressor suction air superheat degree gear is higher The higher, the lower the heating power gear corresponding to the electric heater. In the above solution, the electric heater is used for heating, which has the advantages of flexible application and fast adjustment speed, and can ensure that the refrigerant sucked by the compressor is a gaseous refrigerant. Of course, the output power of the electric heater can also be determined acc...

Embodiment 3

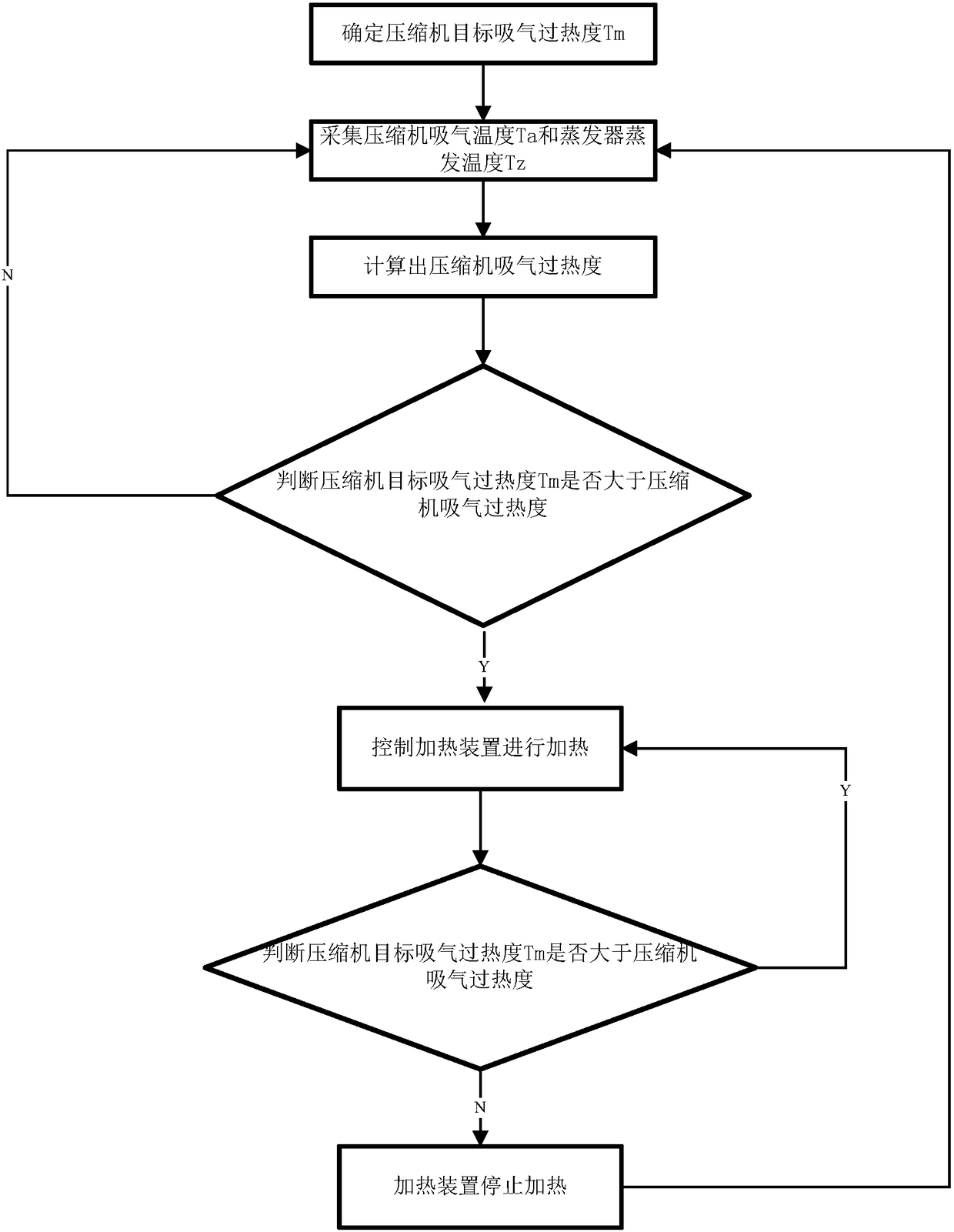

[0069] see figure 2 As shown, the heat pump water heater control method of the present invention includes the following steps:

[0070] S1. The controller determines the target suction superheat Tm;

[0071]Among them, in step S1, the controller determines the target suction superheat of the compressor including three schemes, scheme 1: receiving user input instructions to determine the target suction superheat of the heat pump water heater; scheme 2: the controller determines the compressor target according to the ambient temperature Suction superheat; scheme three: the controller determines the target suction superheat according to the set default value, wherein the default value can be set by the manufacturer according to experience, and the default value ranges from 0 to 15. Preferably, the default value It is 1 to 10, the most preferred, and the default value is 5. Users can choose a plan that suits them, or when the adjustment effect of one of the plans is not good, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com