Steam turbine generator set with direct combustion heating function

A steam turbine generator set and steam turbine technology, which is applied in steam engine installations, machines/engines, mechanical equipment, etc., can solve the problems of impossible to reach the high temperature level of gas turbines, difficult to further increase the steam temperature, etc., and reduce pollutant emissions and carbon dioxide emissions. , cost reduction, thermal efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with specific embodiment, further illustrate the present invention.

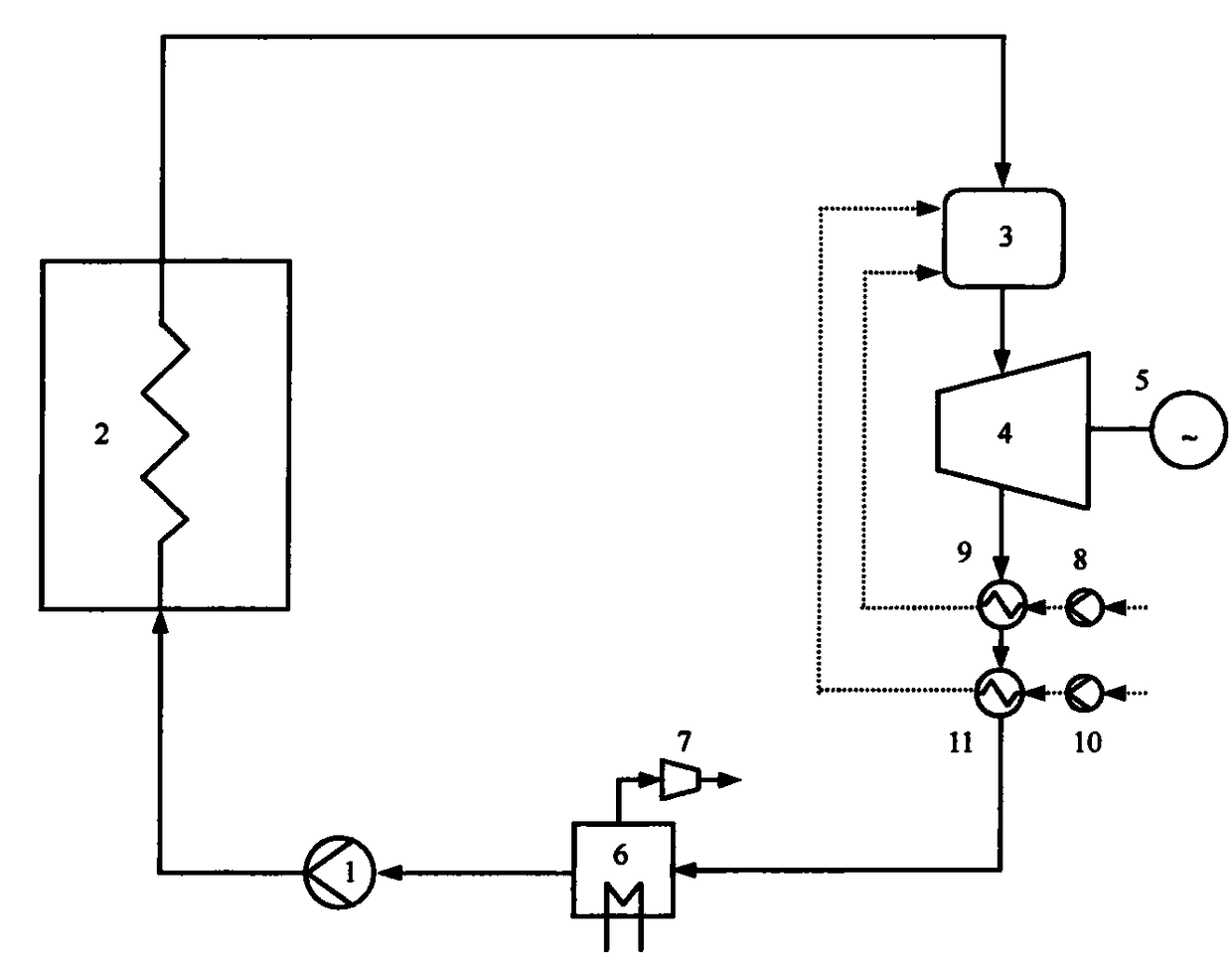

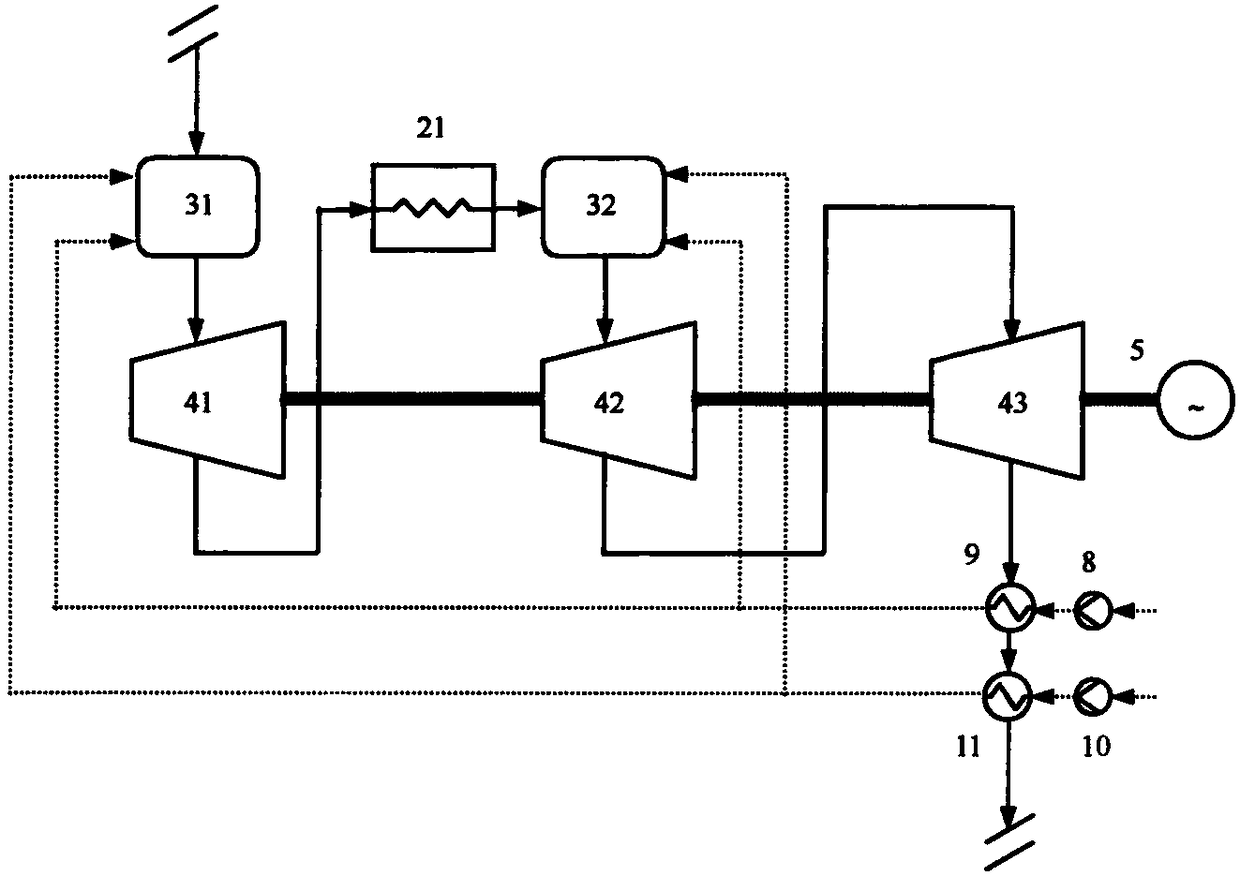

[0024] The steam turbine generator set with direct combustion heating provided by the present invention is to add a combustion chamber to the conventional steam turbine generator set, direct combustion heating, and increase the steam temperature, and the combustion chamber is arranged close to the steam inlet of the steam turbine. For a basic steam Rankine cycle system such as figure 1 As shown, the outlet of circulating water pump 1 is connected to the inlet of boiler 2, the outlet of boiler 2 is connected to the inlet of combustion chamber 3; the outlet of combustion chamber 3 is connected to the steam inlet of steam turbine 4; the steam turbine 4 is connected to generator 5; the exhaust port of steam turbine 4 is connected to fuel preheater 9 High temperature side inlet, fuel preheater 9 high temperature side outlet connected to oxidant preheater 11 high temperature side inlet,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap