Testing platform mechanism of high-speed horizontal type stripping force testing machine

A test platform and peel force technology, applied in the direction of measuring devices, measuring fluid pressure, instruments, etc., can solve the problems of inability to adjust the angle, narrow test range, rigid operation, etc., to achieve convenient operation, strong market competitiveness, and accurate angle adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

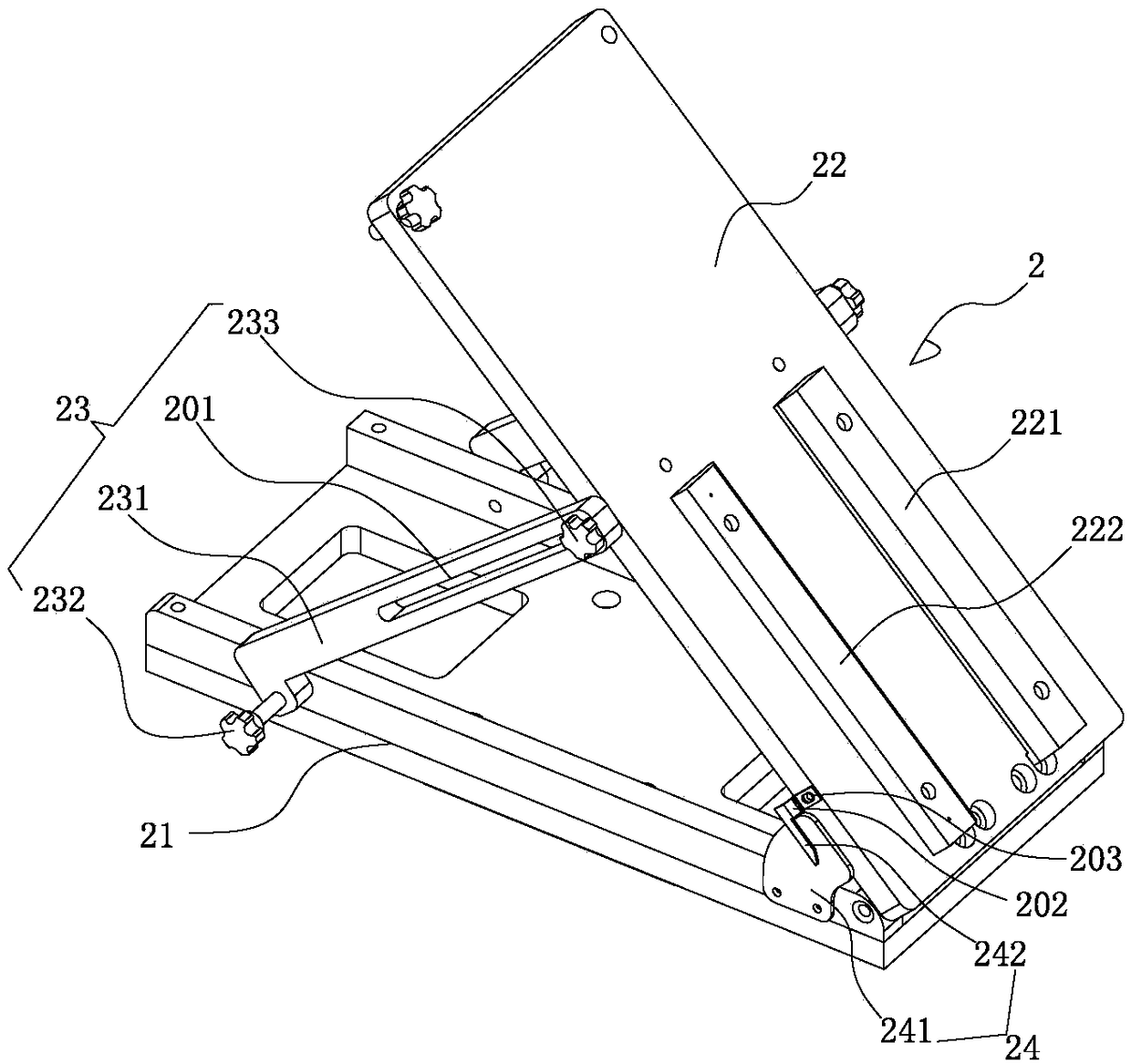

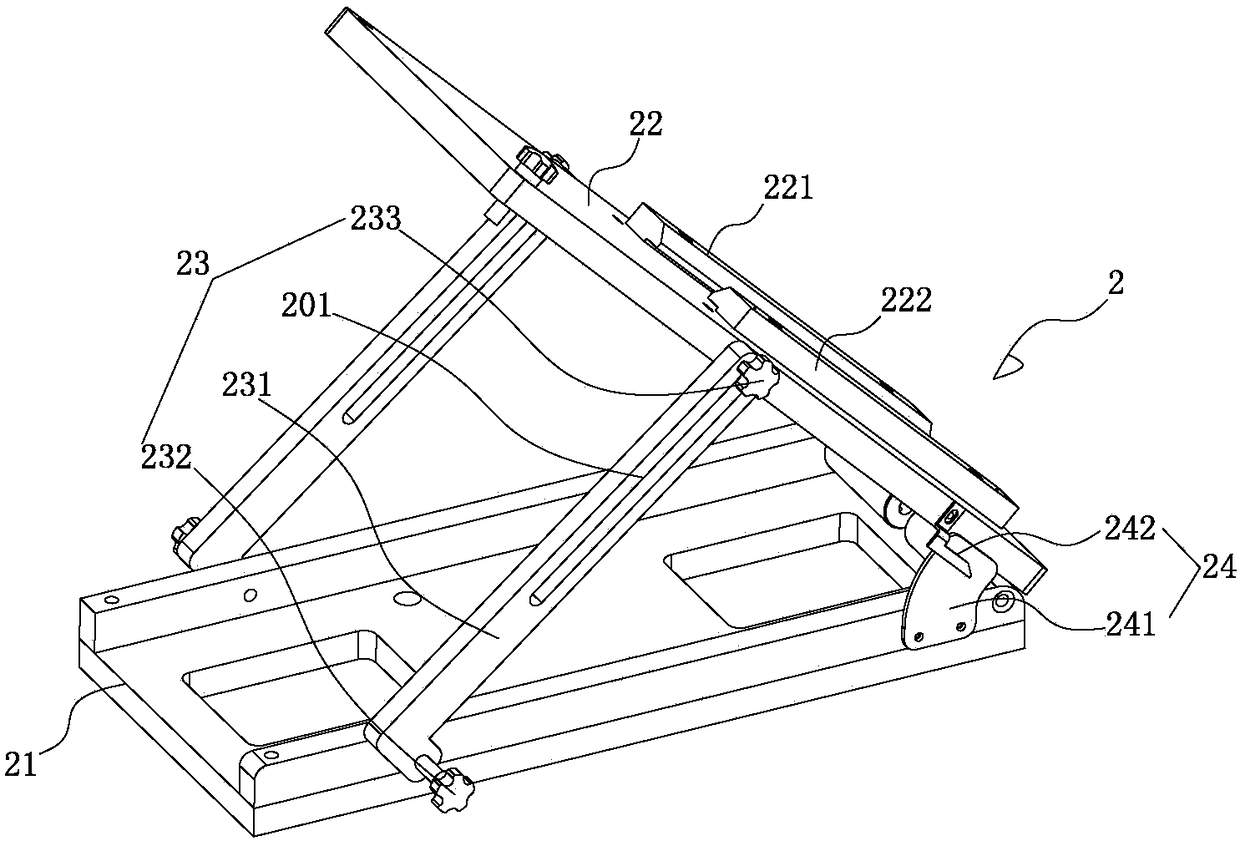

[0018] See figure 1 , 2 As shown, it is a test platform mechanism of a high-speed horizontal peel force testing machine, the test platform mechanism 2 includes a first base 21, a test platform 22 hinged at one end of the first base 21 and located above the first base 21 1. Installed between the first base 21 and the test platform 22 and used to support the angle adjustment module 23 of the positioning test platform 22 and the angle display module 24 arranged at the hinge of the first base 21 and the test platform 22, the first base 21 is installed on the servo motor drive mechanism 3, and exposed on the upper end surface of the machine base 1; on the table of the test platform 22, there are first and second pressure plates 221 for clamping the steel plate for sticking the product to be tested , 222, the test platform 22 adjusts the angle relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com