Drivable rotary steel collar assembly of which inside and outside are both supported by spherical rolling path

A technology of steel rings and components, applied in the field of driveable rotating ring components, can solve problems such as affecting the spinning speed, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

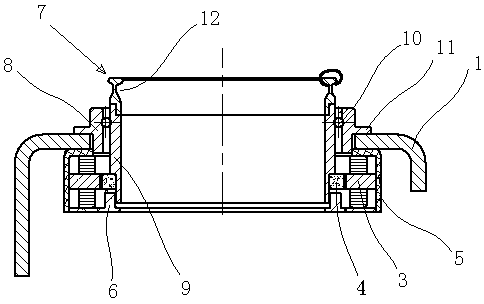

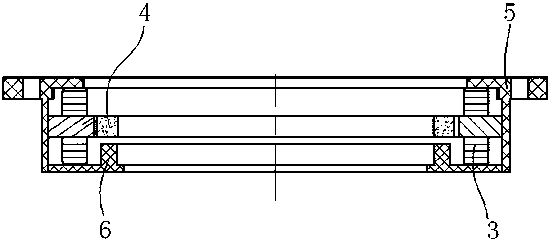

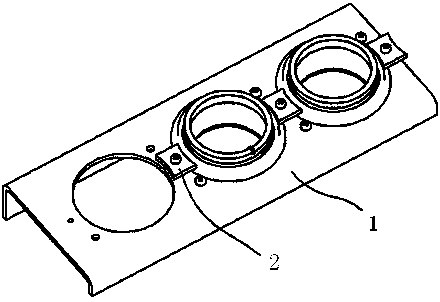

[0014] Such as figure 1 with figure 2 As shown in the figure, a drivable rotating ring assembly supported by spherical raceways inside and outside, it includes a rotating ring assembly and a ring plate 1, and several mounting holes for placing the rotating ring assembly are opened at equal intervals on the ring plate 1 , the rotating ring assembly is set in the installation hole and then crimped on the ring plate 1 through the pressure plate 2, the rotating ring assembly includes the motor assembly and the ring assembly, such as figure 2 , the motor assembly is composed of motor stator 3, motor rotor 4, motor housing 5 and motor cover 6, and the ring assembly is composed of traveler track 7, ring outer ring 8, ring inner ring 9 and balls 10, The steel ring outer ring 8 is set in the installation hole, the steel ring outer ring 8 and the steel ring inner ring 9 are sandwiched with balls 10 to form a steel ring bearing, and the steel ring track 7 is press-fitted on the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com