Display panel of horizontal electric field type, manufacturing method of display panel, and display device

A technology of display panel and horizontal electric field, applied in instrument, nonlinear optics, optics, etc., can solve the problem of light leakage of display panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In-Plane Switching (IPS, In-Plane Switching) and Advanced Super Dimension Switching (ADS, Advanced Super Dimension Switch) modes are commonly used display modes for existing wide-angle LCD panels, also known as horizontal electric field LCD panels.

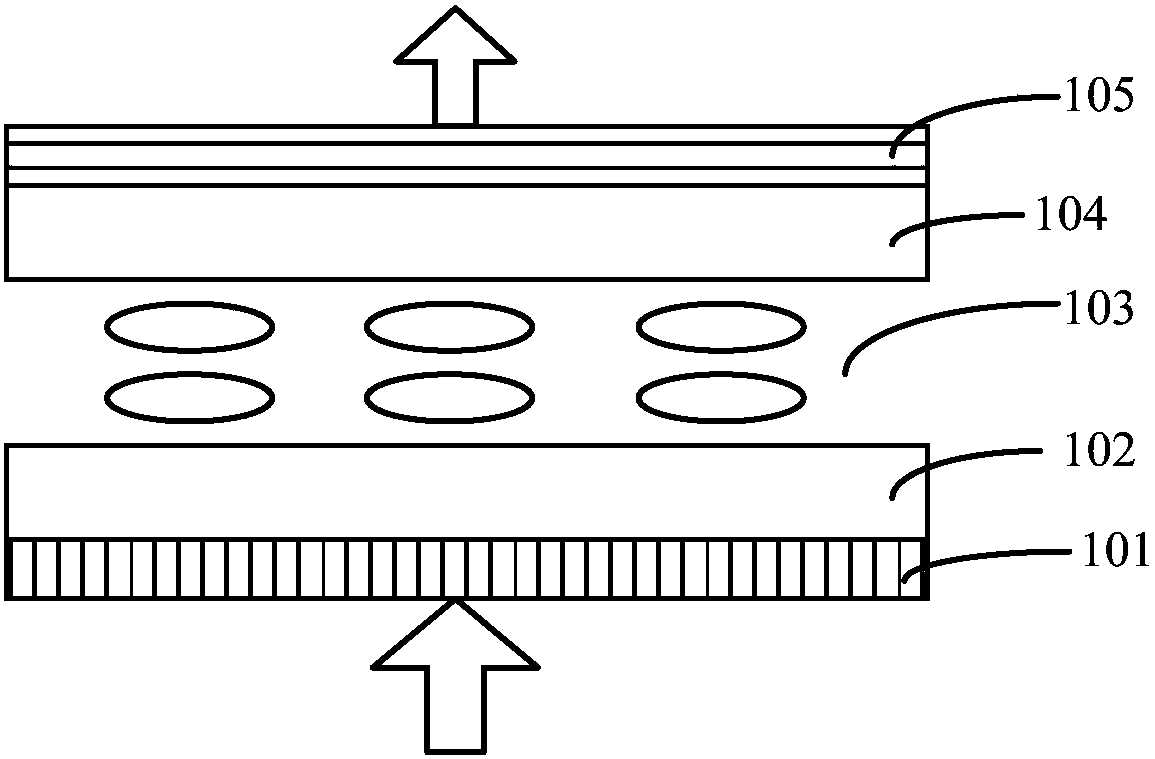

[0049] Take the ADS type LCD as an example for specific description, such as figure 1 As shown, the ADS type LCD includes an opposite substrate 104 and an array substrate 102 , and a liquid crystal layer 103 located between the opposite substrate 104 and the array substrate 102 . In order to ensure normal display, an upper polarizer 105 and a lower polarizer 101 whose light transmission axes are perpendicular to each other are arranged on the outer sides of the opposite substrate 104 and the array substrate 102 respectively. Since the liquid crystal cannot emit light, the liquid crystal display panel also needs to be provided with a backlight ( figure 1not shown). The light emitted by the backlight is emitted through the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com