Through hole for reflection type LCD

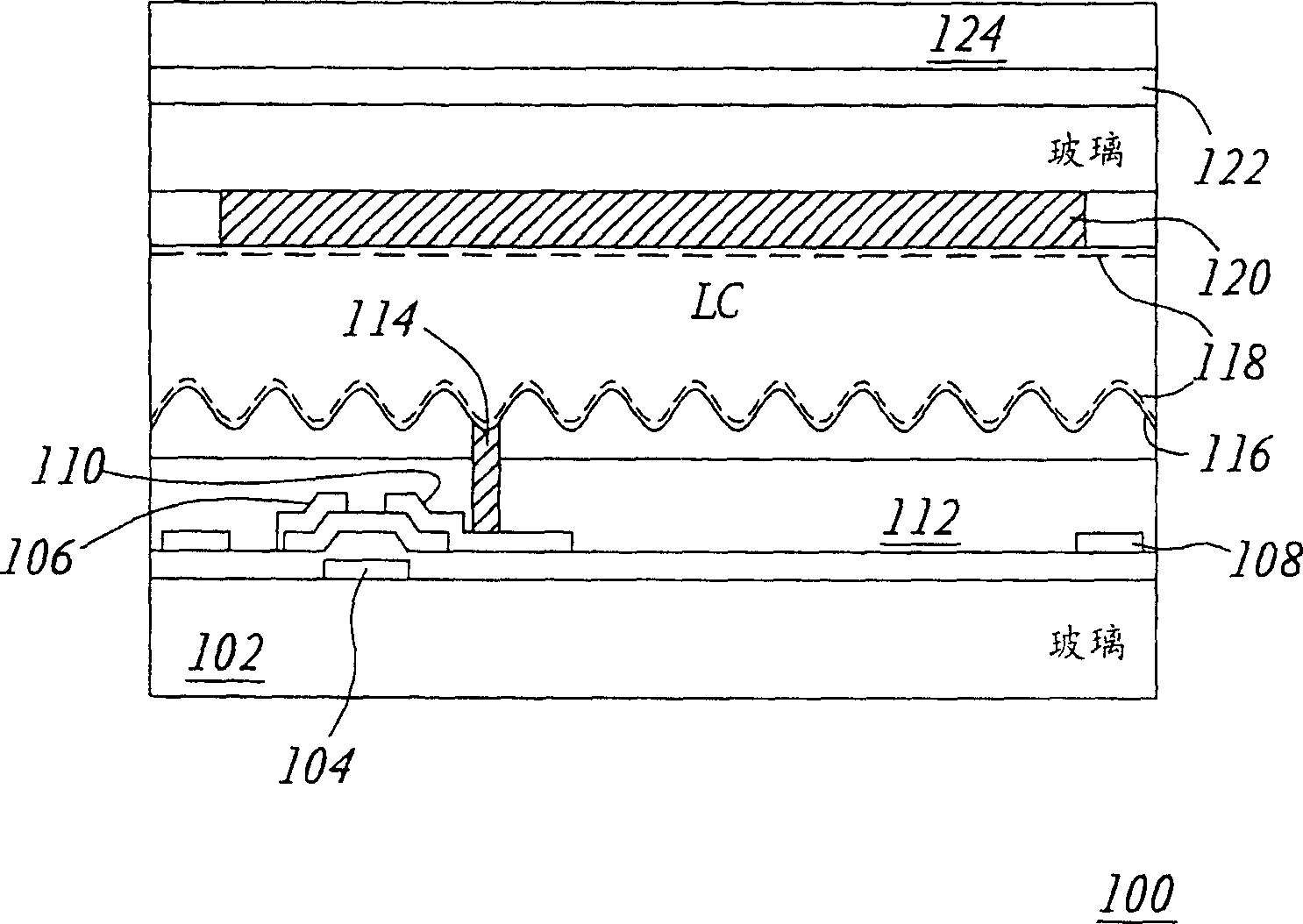

A liquid crystal display, reflective technology, used in static indicators, instruments, optics, etc., to solve problems such as incomplete grinding, light leakage in dark states, and poor alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

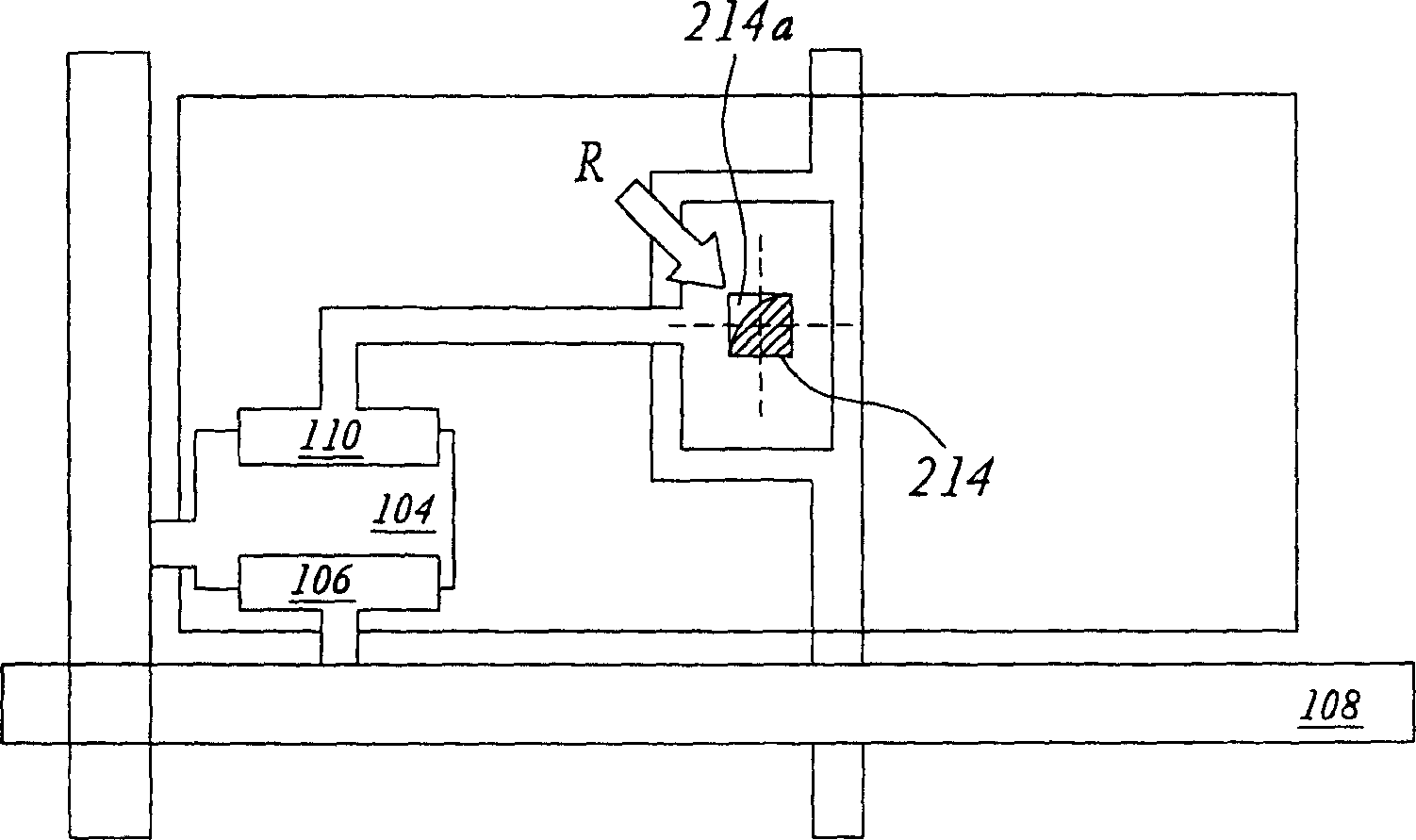

[0030] Such as figure 2 As shown in the traditional square through hole in , relative to the corner 214a of the brushing direction, there will be a dead angle that cannot be brushed. For this, the present invention utilizes the method of changing the shape and profile of the through hole to improve the situation of dark state light leakage caused by misalignment.

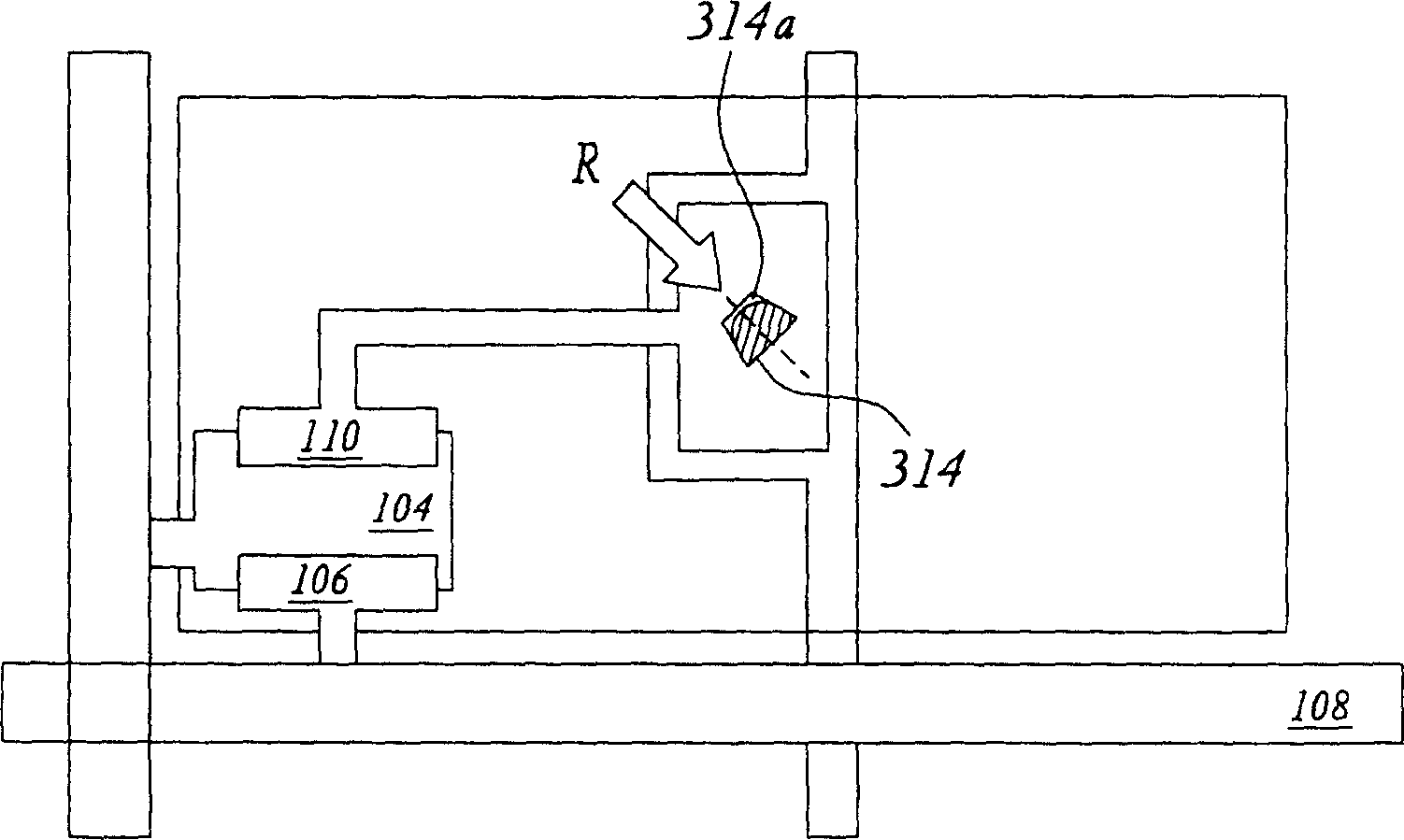

[0031] Please refer to image 3 , which shows a schematic top view of the through hole according to the first embodiment of the present invention. image 3 Among them, the end of the through hole 314 relative to the source direction R of the brush movement is reduced, and the shape is also changed from a square to a trapezoid, that is, the short side of the trapezoid is relative to the direction of the matching movement source. In addition, it is more preferable to rotate the through hole 314 so that its central axis of symmetry is parallel to the brushing direction R. As shown in FIG. According to the experimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com