Goods feeding device for plastic bag production

A plastic bag and equipment technology, applied in the field of loading equipment for plastic bag production, can solve the problems of heavy workload, time-consuming and laborious, etc., and achieve the effect of convenient loading of plastic bags on the car

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

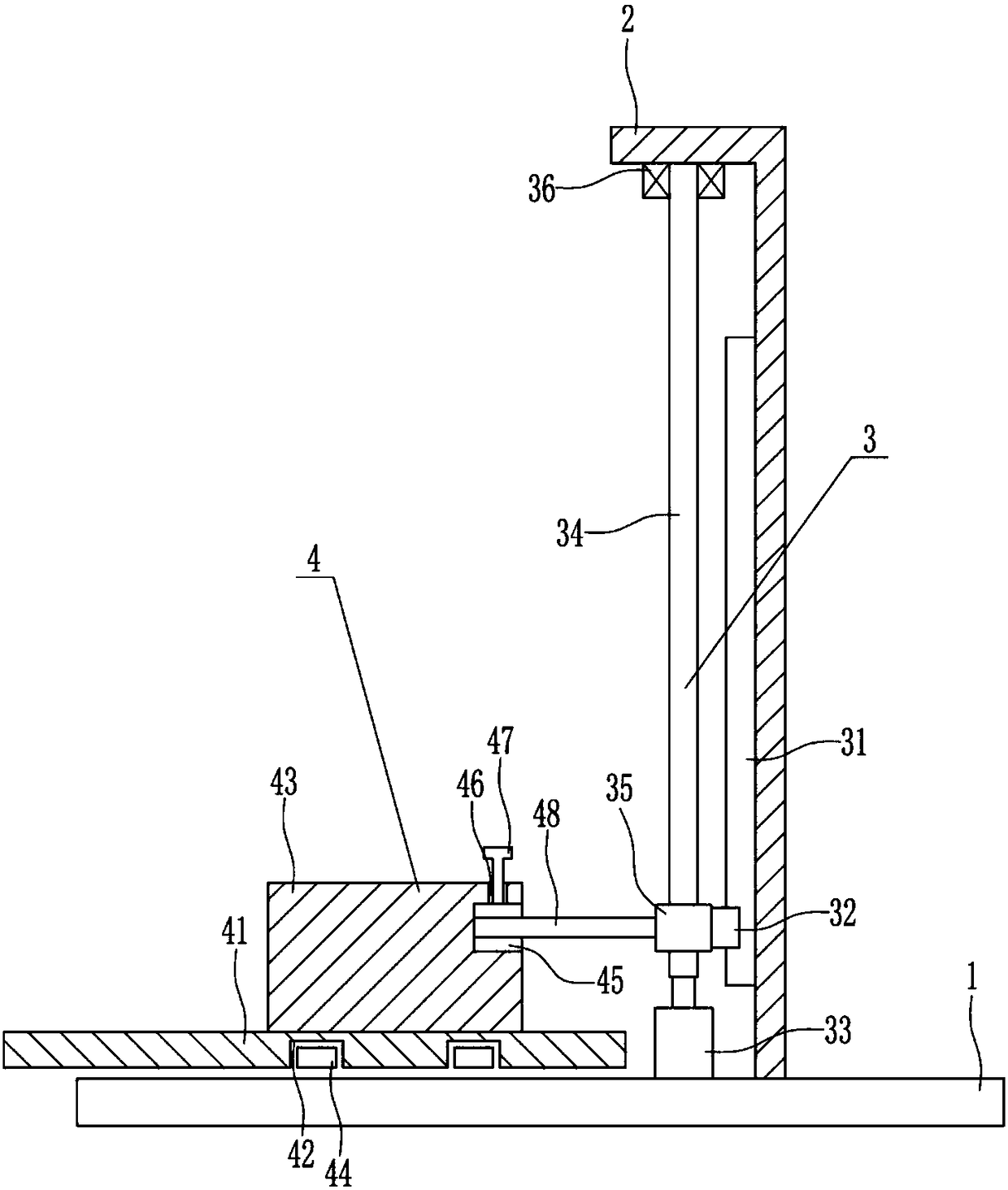

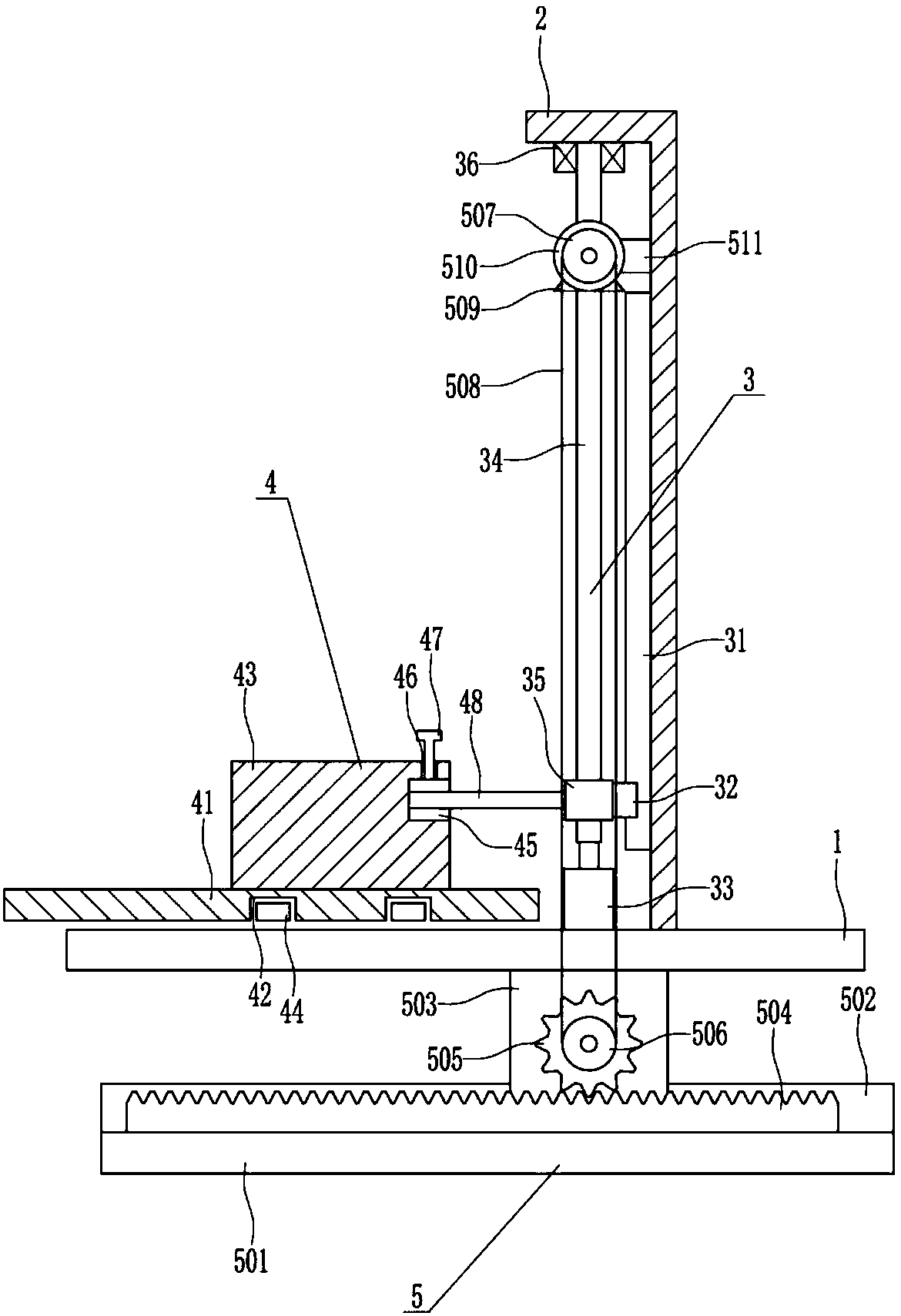

[0028] A loading equipment for plastic bag production, such as Figure 1-4 As shown, it includes a first bottom plate 1, a 7-type plate 2, a lifting device 3 and a placement device 4. The right side of the top of the first bottom plate 1 is connected with a 7-type plate 2, and the right side of the 7-type plate 2 is equipped with a lifting device 3. A placement device 4 is provided on the left side of the top of the first bottom plate 1 , and the placement device 4 is connected to the lifting device 3 .

Embodiment 2

[0030] A loading equipment for plastic bag production, such as Figure 1-4 As shown, it includes a first bottom plate 1, a 7-type plate 2, a lifting device 3 and a placement device 4. The right side of the top of the first bottom plate 1 is connected with a 7-type plate 2, and the right side of the 7-type plate 2 is equipped with a lifting device 3. A placement device 4 is provided on the left side of the top of the first bottom plate 1 , and the placement device 4 is connected to the lifting device 3 .

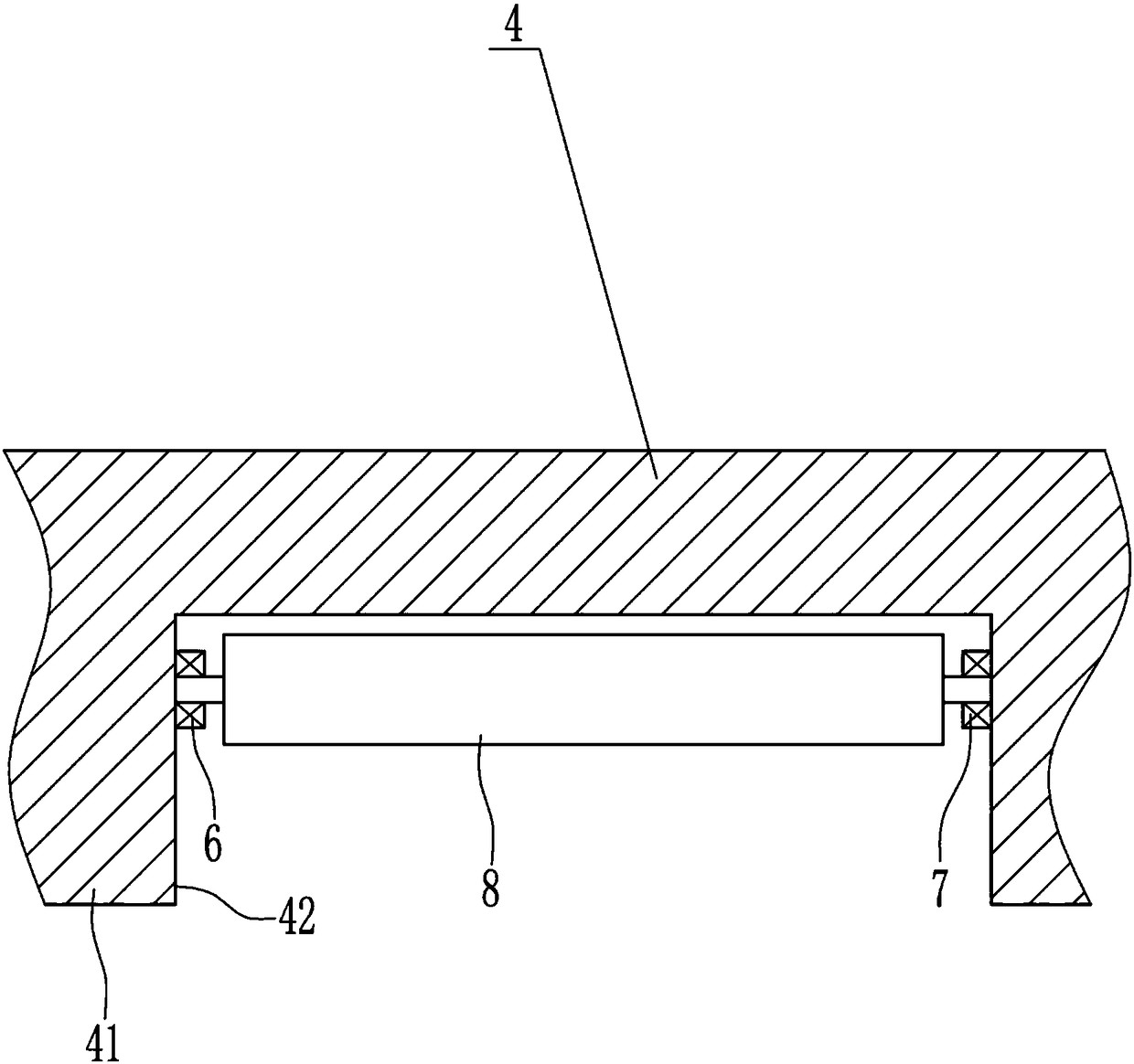

[0031] The placing device 4 includes a placing plate 41, a vertical plate 43, a connecting plate 44, a second screw rod 47 and a cross bar 48, the left side of the top of the first base plate 1 is provided with a placing plate 41 and a vertical plate 43, and the vertical plate 43 is located on the placing plate 41. At the rear, there are two first grooves 42 on the right side of the bottom of the placement plate 41, and the lowermost part of the front side of the vertical pla...

Embodiment 3

[0033] A loading equipment for plastic bag production, such as Figure 1-4 As shown, it includes a first bottom plate 1, a 7-type plate 2, a lifting device 3 and a placement device 4. The right side of the top of the first bottom plate 1 is connected with a 7-type plate 2, and the right side of the 7-type plate 2 is equipped with a lifting device 3. A placement device 4 is provided on the left side of the top of the first bottom plate 1 , and the placement device 4 is connected to the lifting device 3 .

[0034]The placing device 4 includes a placing plate 41, a vertical plate 43, a connecting plate 44, a second screw rod 47 and a cross bar 48, the left side of the top of the first base plate 1 is provided with a placing plate 41 and a vertical plate 43, and the vertical plate 43 is positioned at the placing plate 41. At the rear, there are two first grooves 42 on the right side of the bottom of the placement plate 41, and the lowermost part of the front side of the vertical p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap