Parameter Determination Method in Inclined Wavefront Interferometry Aspheric Surface

A technology of parameter determination and wavefront interference, applied in measurement devices, instruments, optical devices, etc., can solve problems such as measurement difficulties, and achieve the effect of wide application range, accurate calculation, and clear steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

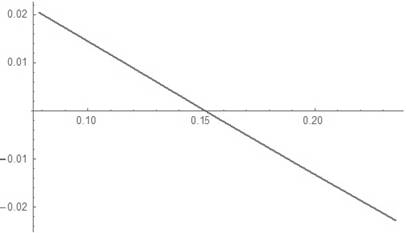

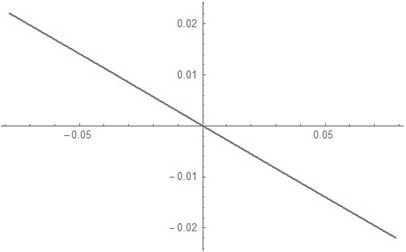

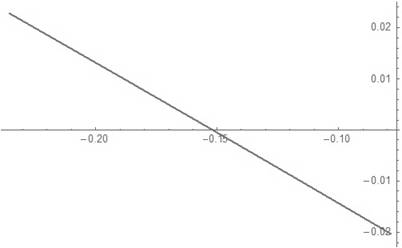

[0047] It is known that the equation of the aspheric surface to be measured is An ellipse with a diameter of 190mm and a coordinate system established with the center of the circle as the origin. The pixel size of the CCD is P=7μm. This is a typical parameter. The pixel size of many industrial cameras can reach this value. The resolution The pixel size of the higher camera is a fraction of the above value; the measurement wavelength is selected as λ=632.8nm, which is the emission wavelength of a common helium-neon laser; in order to ensure a certain redundancy in the design, every 2 pixels contain One stripe, that is, n=2, the maximum allowable deviation angle |Δ calculated according to formula (11) limit |=0.0226rad. Then calculate the ellipse tangent and normal vectors according to the aspherical equation, and the angular interval is Segment the curve, and calculate the angle between the outgoing ray and the incident ray of each mirror point, the light emitted at the ori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com