Scaffold fastener slipping alarm device and installation method thereof

An alarm device and scaffolding technology, which is applied to the attachments of scaffolding, buildings, housing structure support, etc., can solve problems such as casualties and other problems, and achieve the effect of preventing the failure or false alarm of the alarm device, with clear steps and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

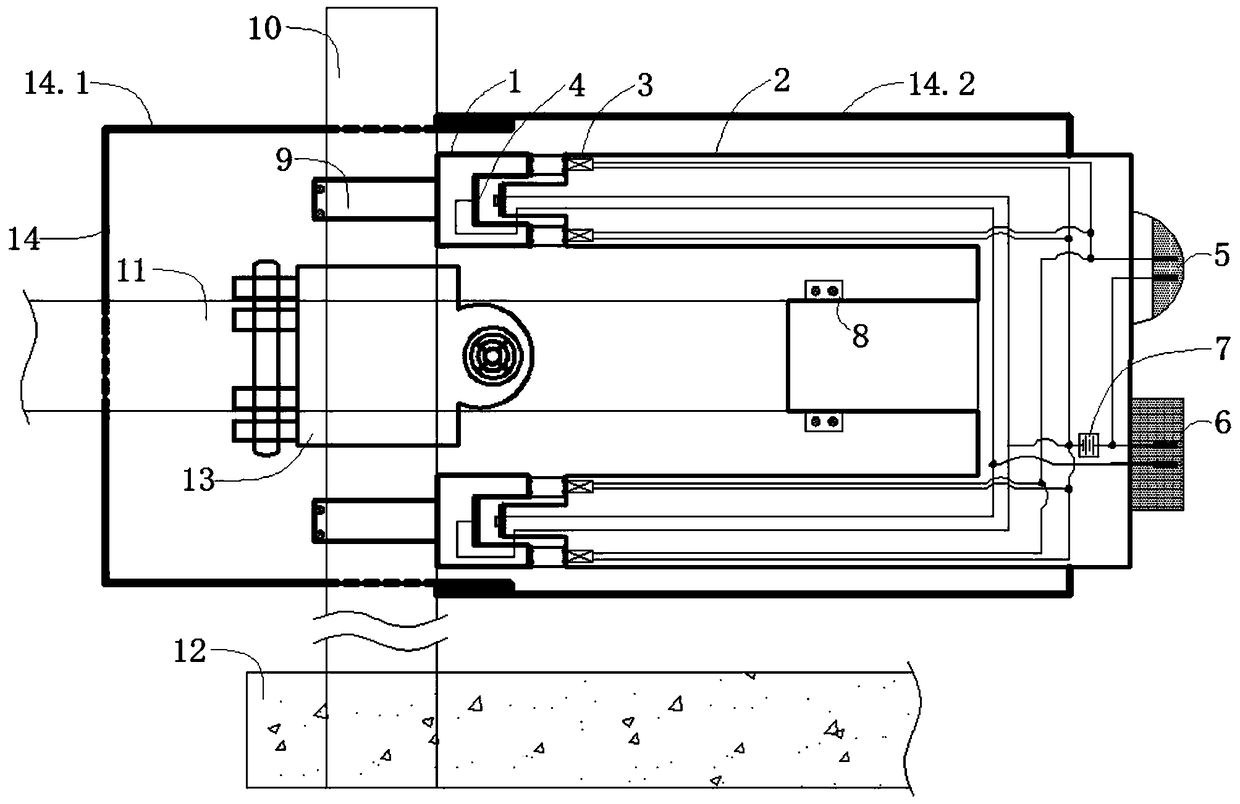

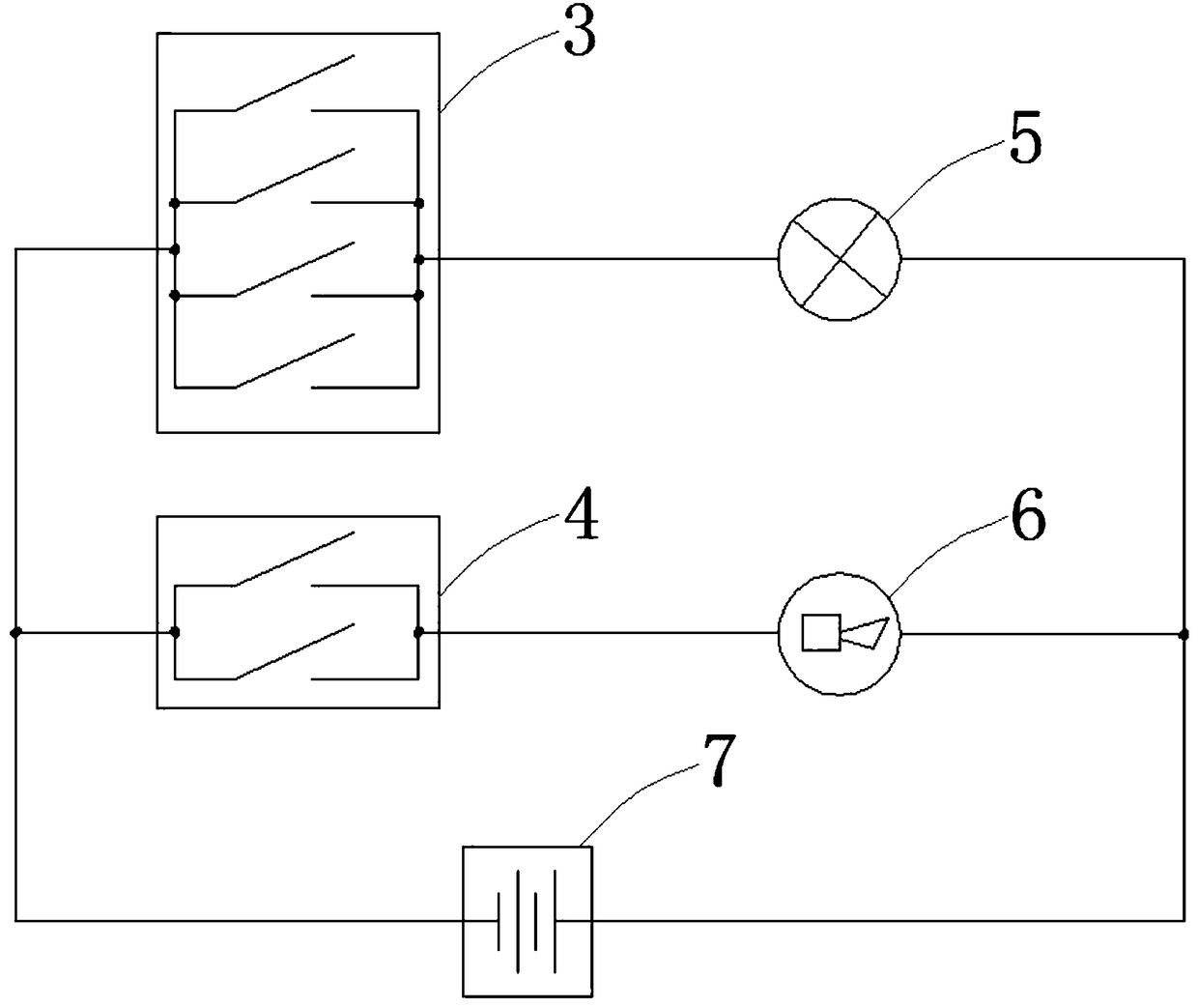

[0037] Scaffold fastener slipping alarm device, such as figure 1 with figure 2 As shown, it includes a vertical bar 10 and a cross bar 11 and a fastener 13 for fastening the vertical bar 10 and the cross bar 11. The bottom of the vertical bar 10 is fixed in the main concrete structure 12, and it also includes a limiting device and a warning device. The device includes an E-shaped sleeve 2 fixed to the end of the cross bar 11 through the first buckle 8. The limit device also includes a U-shaped sleeve 1 fixed to the side of the vertical pole 10 through the second buckle 9. The E-shaped sleeve 2 includes two upper and lower A protruding head at the end of a protruding section, the top of the protruding head is provided with a first contact, the protruding head is adapted to the cavity of the U-shaped sleeve 1, and the upper surface of the bottom of the cavity of the U-shaped sleeve 1 is provided with a second contact, the first The contact and the second contact form the two p...

Embodiment 2

[0052] Scaffold fastener slipping alarm device, such as figure 1 with figure 2 As shown, it includes a vertical bar 10 and a cross bar 11 and a fastener 13 for fastening the vertical bar 10 and the cross bar 11. The bottom of the vertical bar 10 is fixed in the main concrete structure 12, and it also includes a limiting device and a warning device. The device includes an E-shaped sleeve 2 fixed to the end of the cross bar 11 through the first buckle 8. The limit device also includes a U-shaped sleeve 1 fixed to the side of the vertical pole 10 through the second buckle 9. The E-shaped sleeve 2 includes two upper and lower A protruding head at the end of a protruding section, the top of the protruding head is provided with a first contact, the protruding head is adapted to the cavity of the U-shaped sleeve 1, and the upper surface of the bottom of the cavity of the U-shaped sleeve 1 is provided with a second contact, the first The contact and the second contact form the two p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com