Fatigue deformation acceleration test method for cutter bar

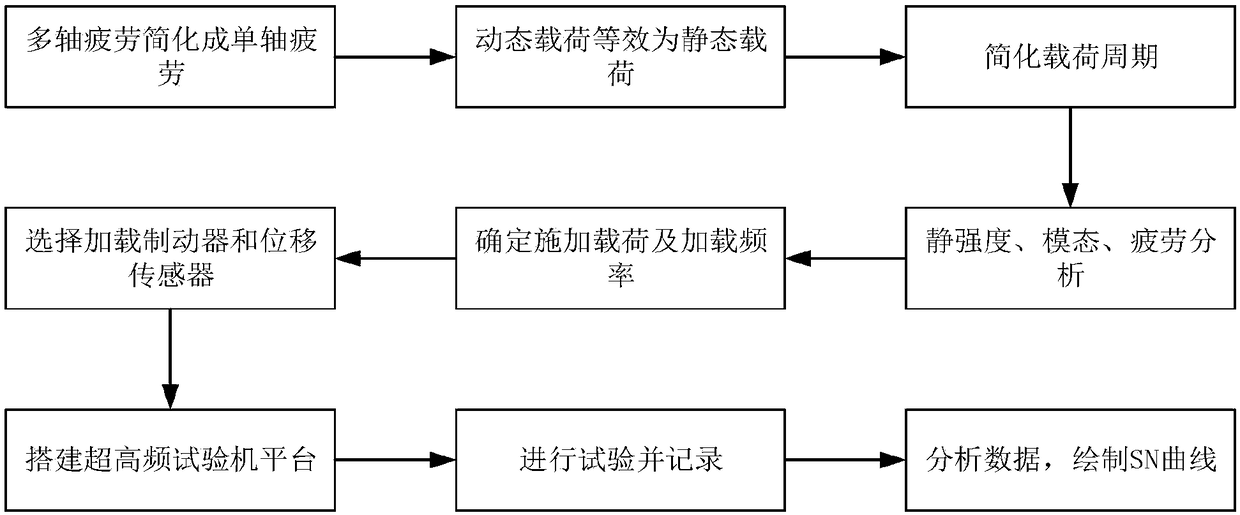

A fatigue deformation and accelerated test technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of long test cycle, low frequency of ordinary fatigue testing machines, etc., to simplify the loading method, speed up The effect of toolholder deformation failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Taking a cylindrical tool bar with a working speed of 2000r / min, a cutting force of 600-1000N, and a material of 40CrNiMo as an example, the specific implementation steps of this method are introduced.

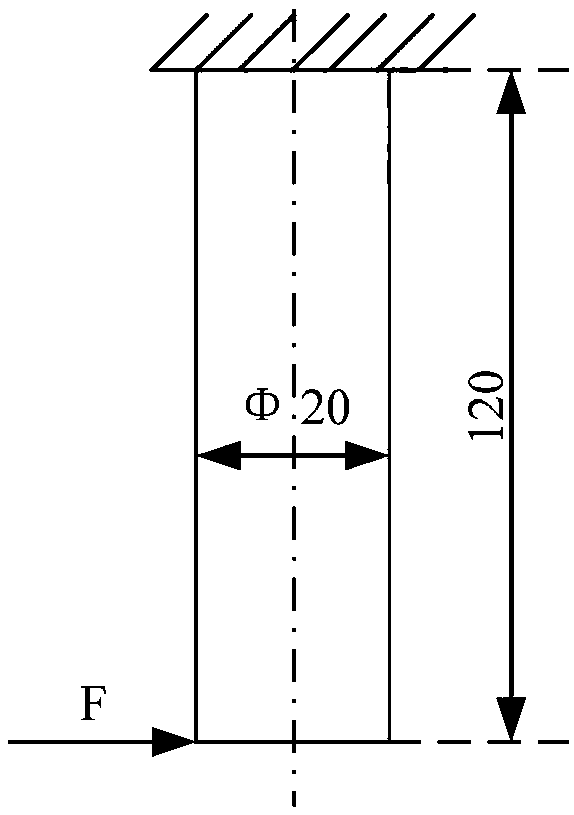

[0029] (1) According to the number of teeth on the cutter rod, the number of fatigue deformation axes of the cutter rod during the cutting process is determined, and the equivalent test method of uniaxial sequential vibration is used to simplify the multi-axial test into a single-axial test problem. At this time, the tool holder can be simplified as a cantilever cylindrical polished rod with a fixed top and a dynamic cutting force at the bottom, such as figure 2 shown; its basic parameters are 120mm in length and 20mm in diameter;

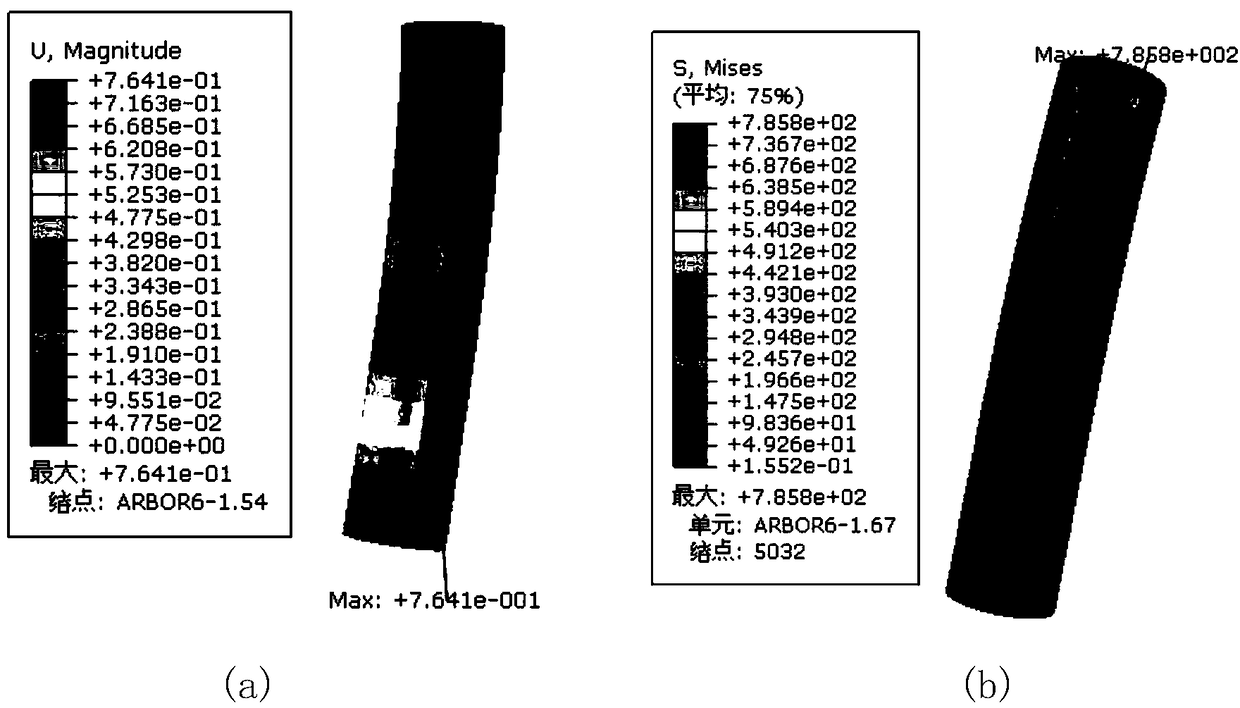

[0030] (2) The dynamic load borne by the tool holder during the actual cutting process is simplified to static load. It is known that the cutting force of the tool holder is in the range of 600-1000N during the cutting process, and 1000N i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com