Air handling in a heavy-duty opposed-piston engine

A technology of opposed piston and engine, applied in the direction of internal combustion piston engine, reciprocating piston engine, engine components, etc., can solve the problems of increasing pumping loss and reducing thermal efficiency of engine braking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

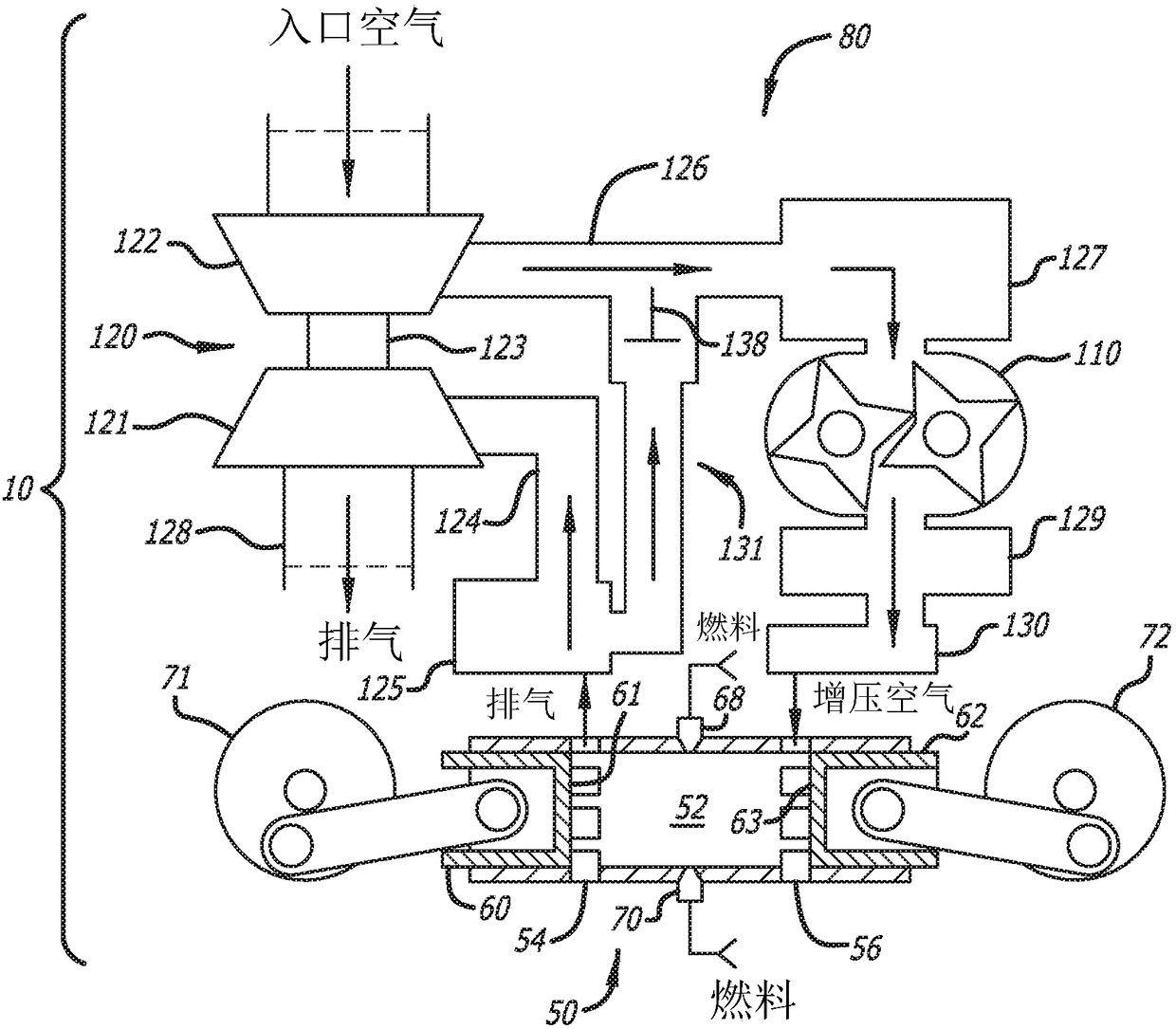

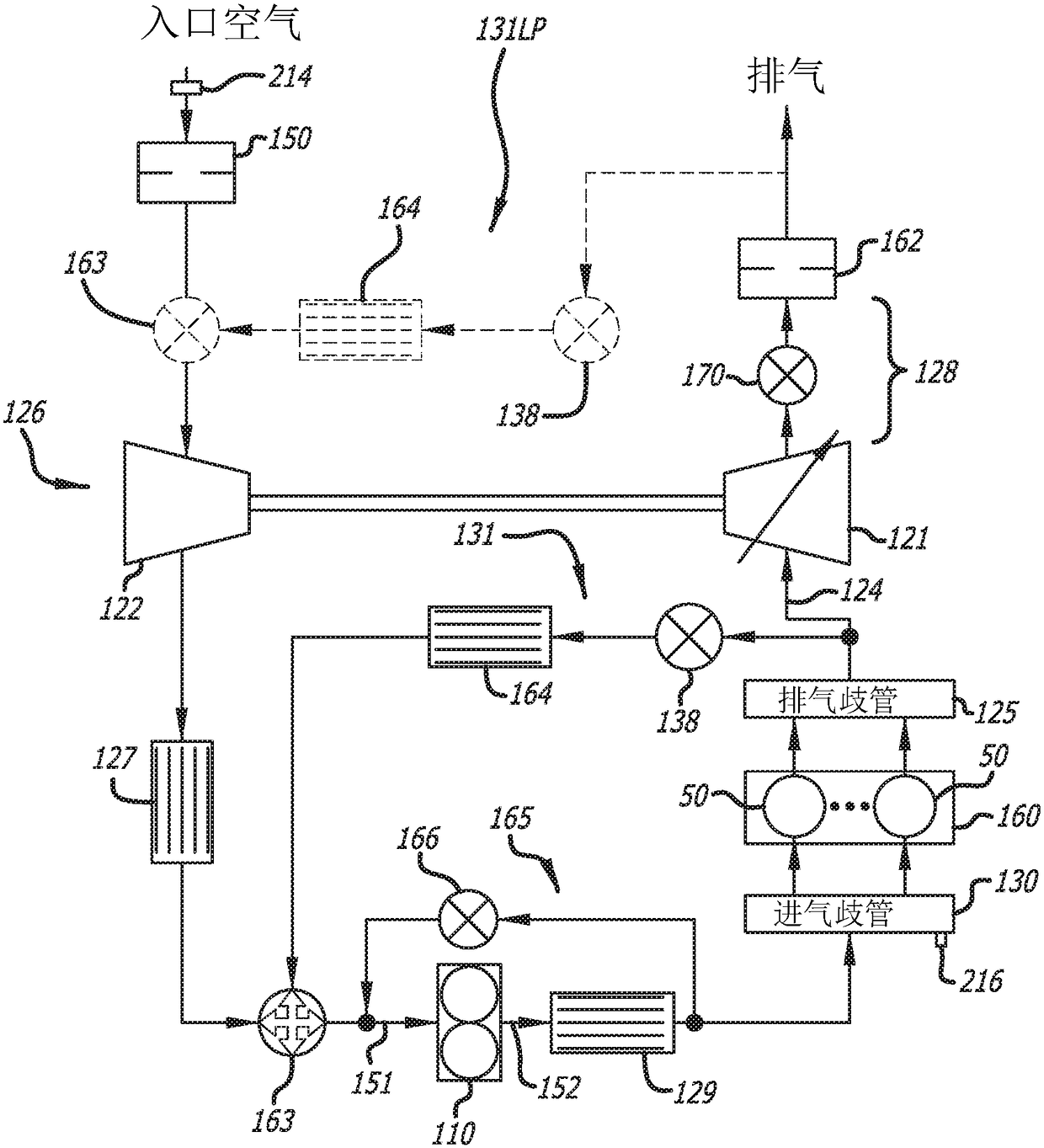

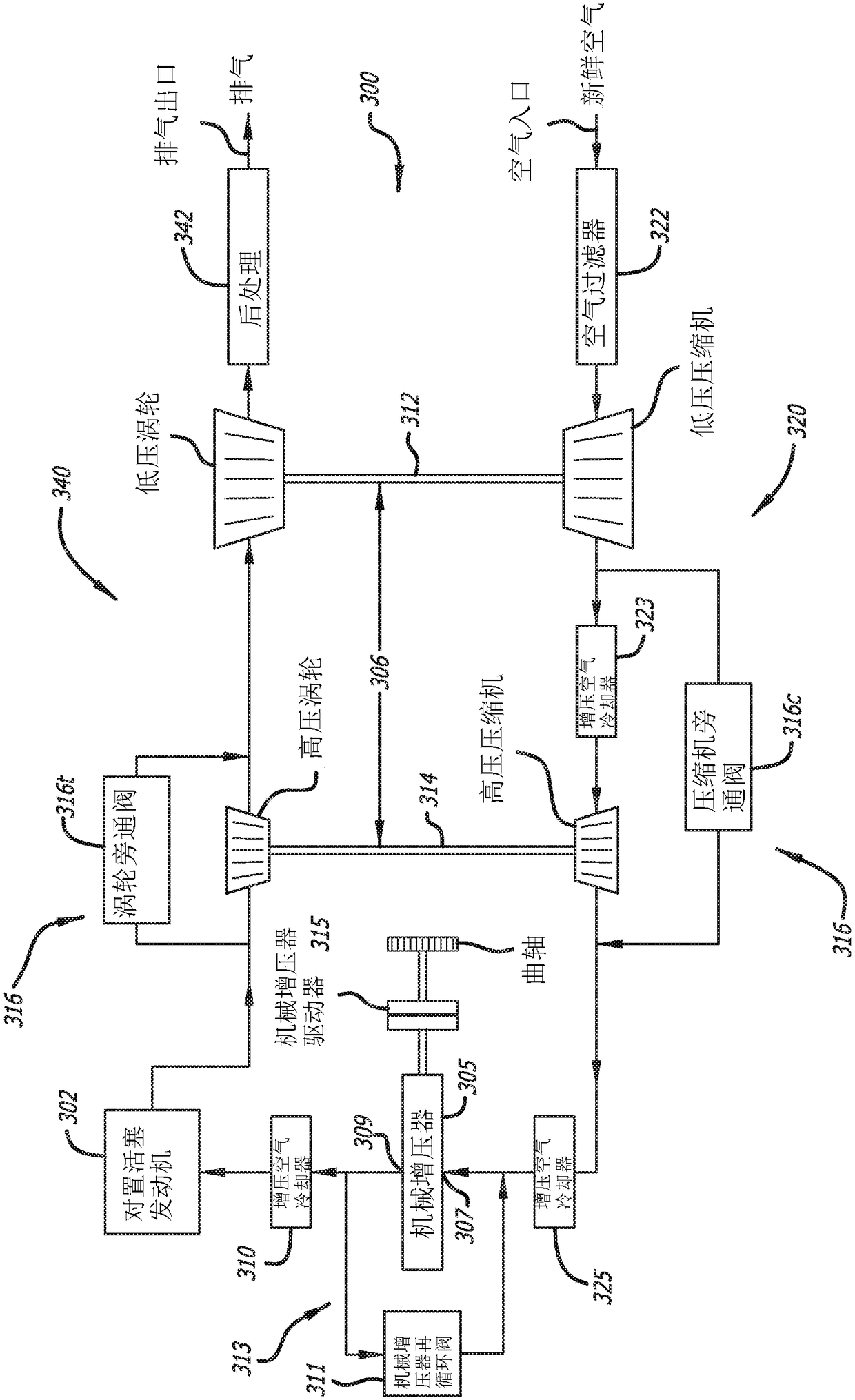

[0025] In this disclosure, "fuel" is any fuel that can be used in an opposed piston engine. The fuel may be a relatively homogeneous composition or blend. For example, the fuel may include diesel fuel, natural gas, gasoline, or another equivalent fuel ignitable by compression, ignition, and / or spark ignition. Further, the description contemplates ignition caused by the compressed air / fuel mixture; however, in some instances, it may be desirable to provide additional mechanisms, such as glow plugs, spark plugs, pilot injection, or laser circuits, to assist in compression ignition.

[0026] According to the present disclosure, when the piston is at or near the TDC position, fuel is injected into the compressed air in the combustion chamber formed between the end surfaces of the opposed pistons. In other aspects, injection may occur earlier in the compression stroke shortly after both ports are closed. The air is preferably pressurized ambient air; however, it may include other...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap