Method and system for processing the detection amount of nitrogen oxides in diesel engines

A diesel engine, nitrogen oxide technology, applied to engine components, combustion engines, machines/engines, etc., can solve problems such as urea injection errors, system monitoring errors, and unfavorable engine precise emission control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

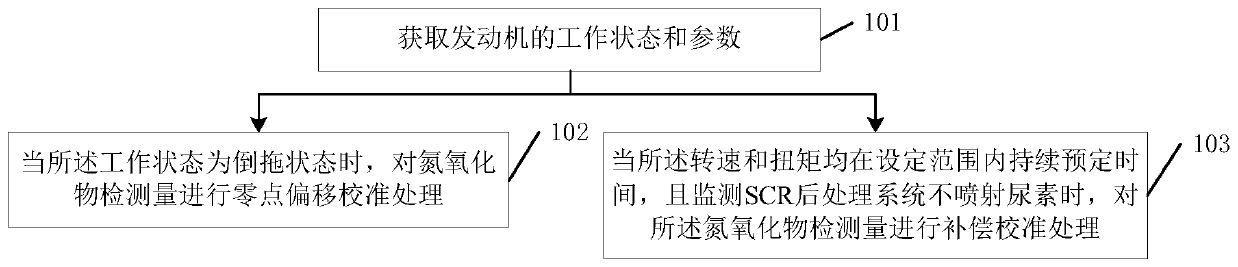

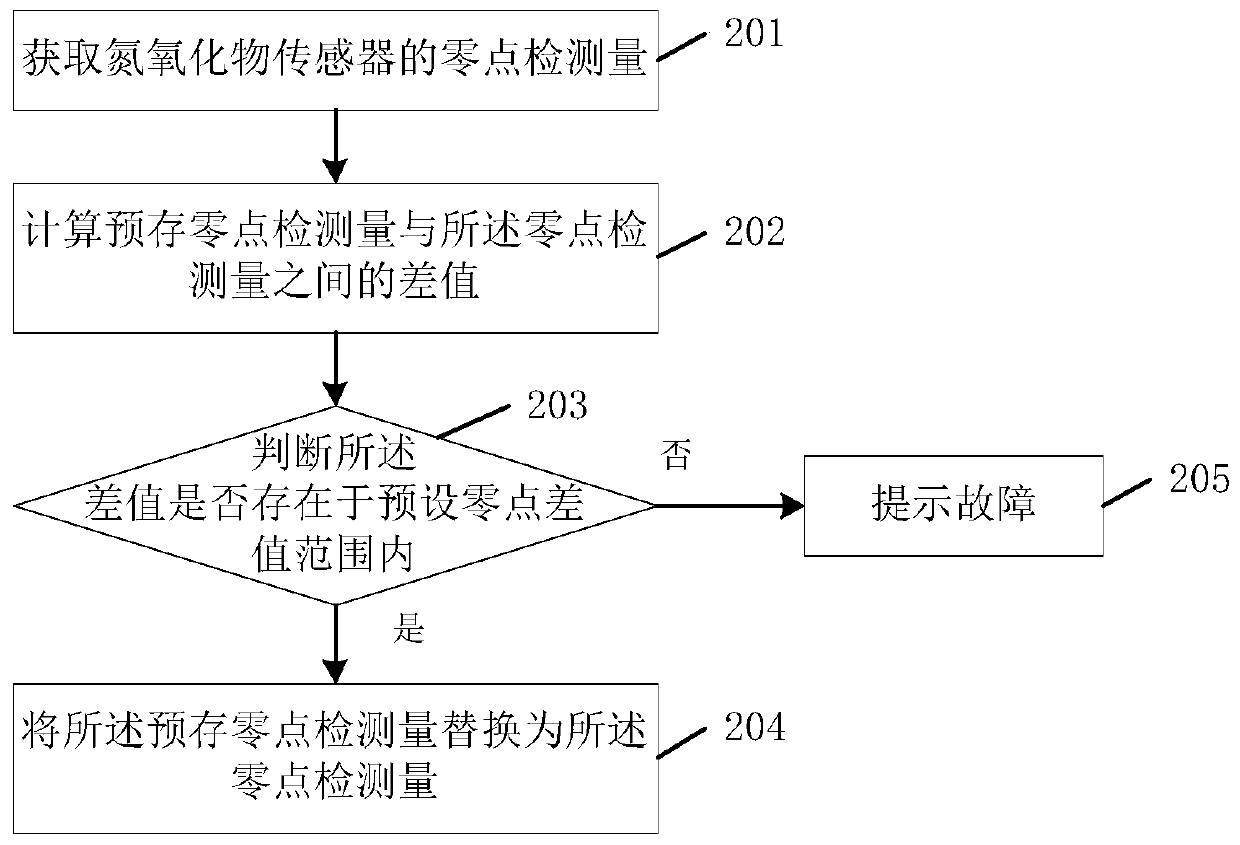

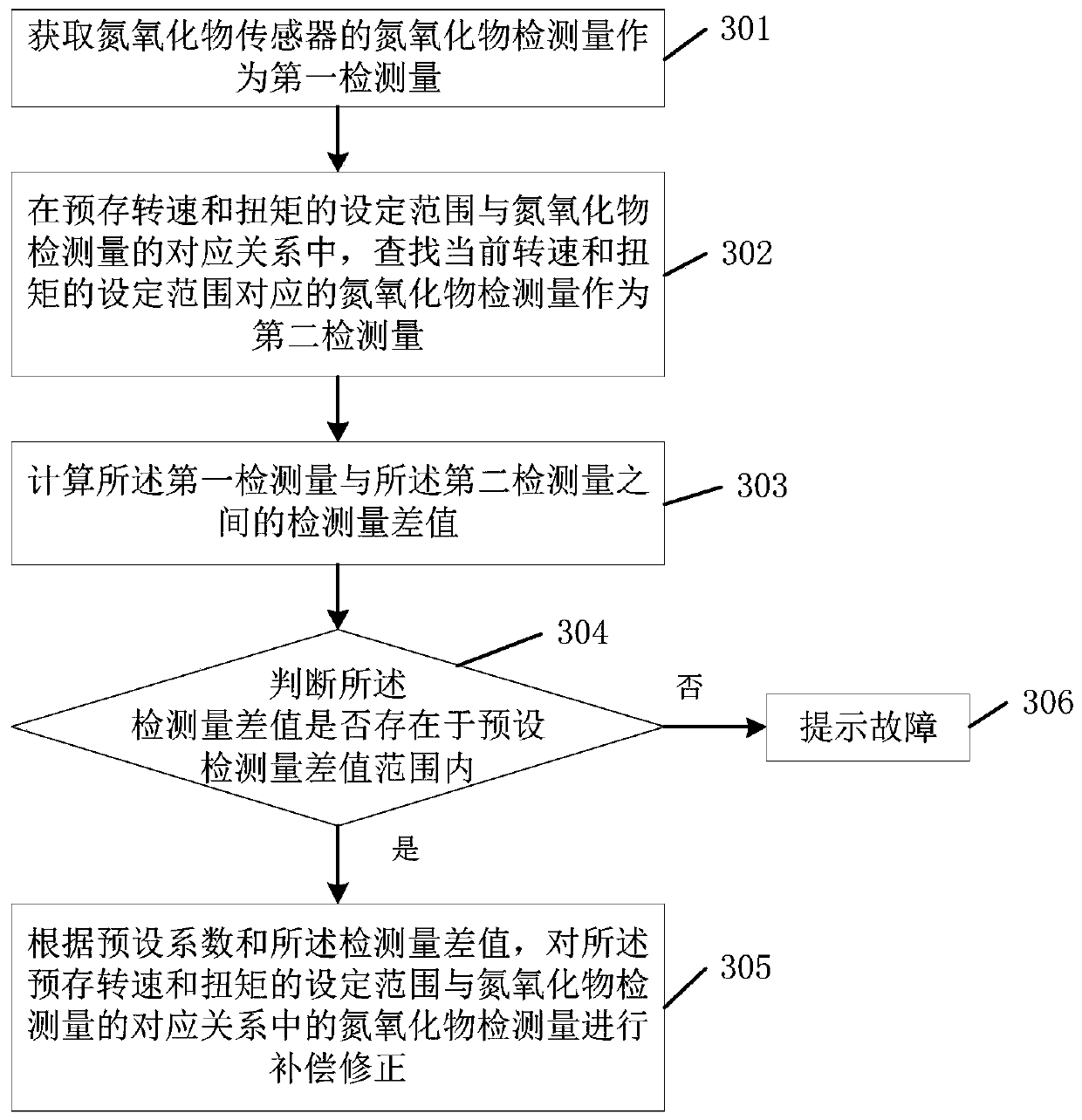

[0047] The embodiment of the present invention is aimed at detecting the emission of nitrogen oxides by the nitrogen oxide sensor, and correcting and compensating when the nitrogen oxide sensor produces a detection deviation, so that the accurate emission of nitrogen oxides can be measured. An embodiment of the present invention provides a method for processing the detected amount of nitrogen oxides in a diesel engine. The execution body of this embodiment is the engine controller, such as figure 1 shown, including the following steps:

[0048] 101. Obtain the working state and parameters of the engine, where the parameters include speed and torque;

[0049] 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com