External hydrocarbon injection device

An injection device, hydrocarbon technology, applied in the direction of exhaust device, muffler device, electronic control of exhaust gas treatment device, etc., can solve the problems of low-carbon hydrogen conversion efficiency, inaccurate hydrocarbon metering injection, low efficiency, etc. Avoiding the effect of hydrocarbon coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical scheme of the present invention will be further described below in conjunction with the drawings.

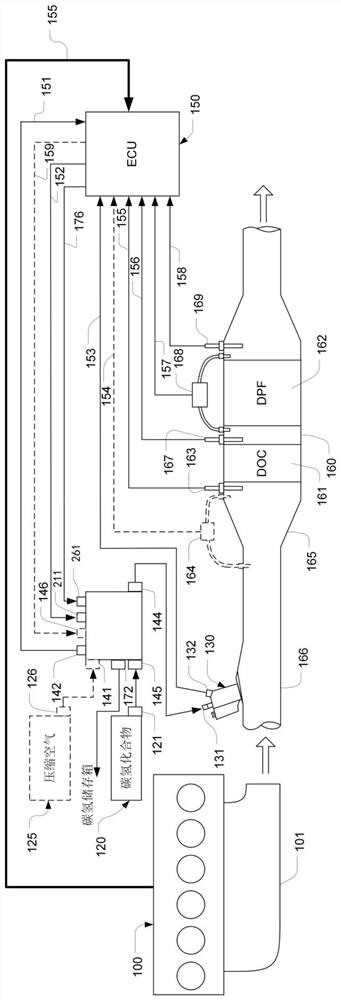

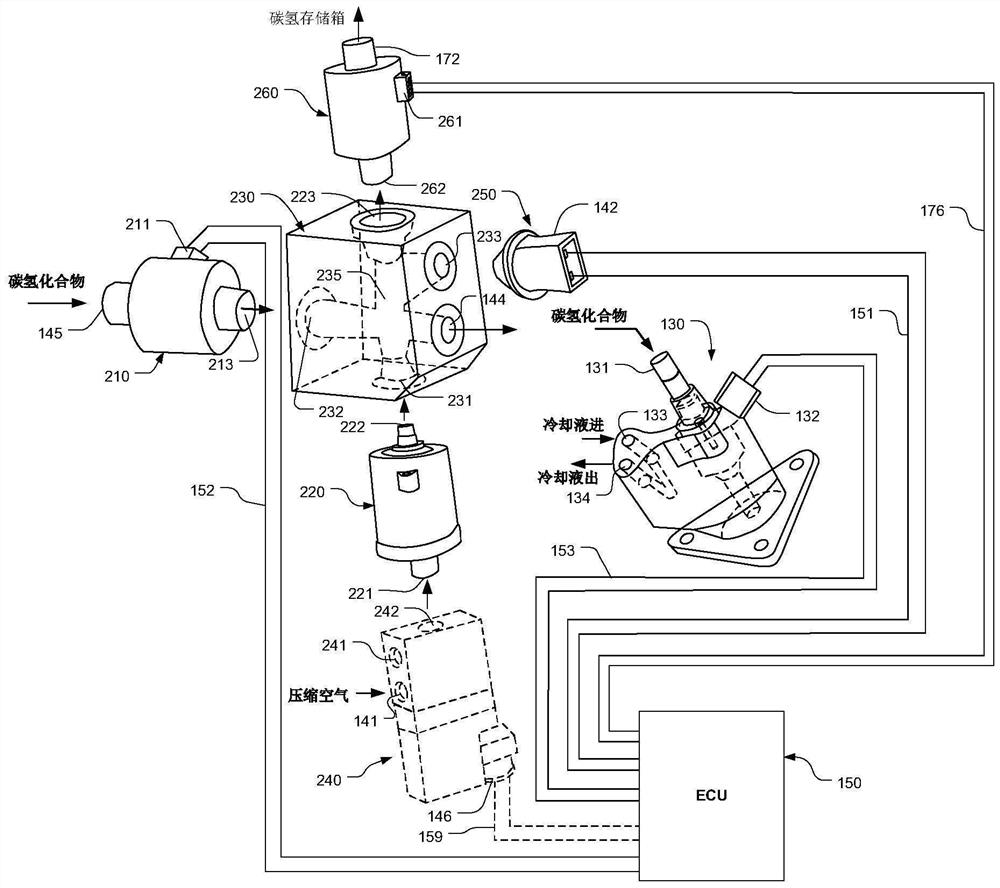

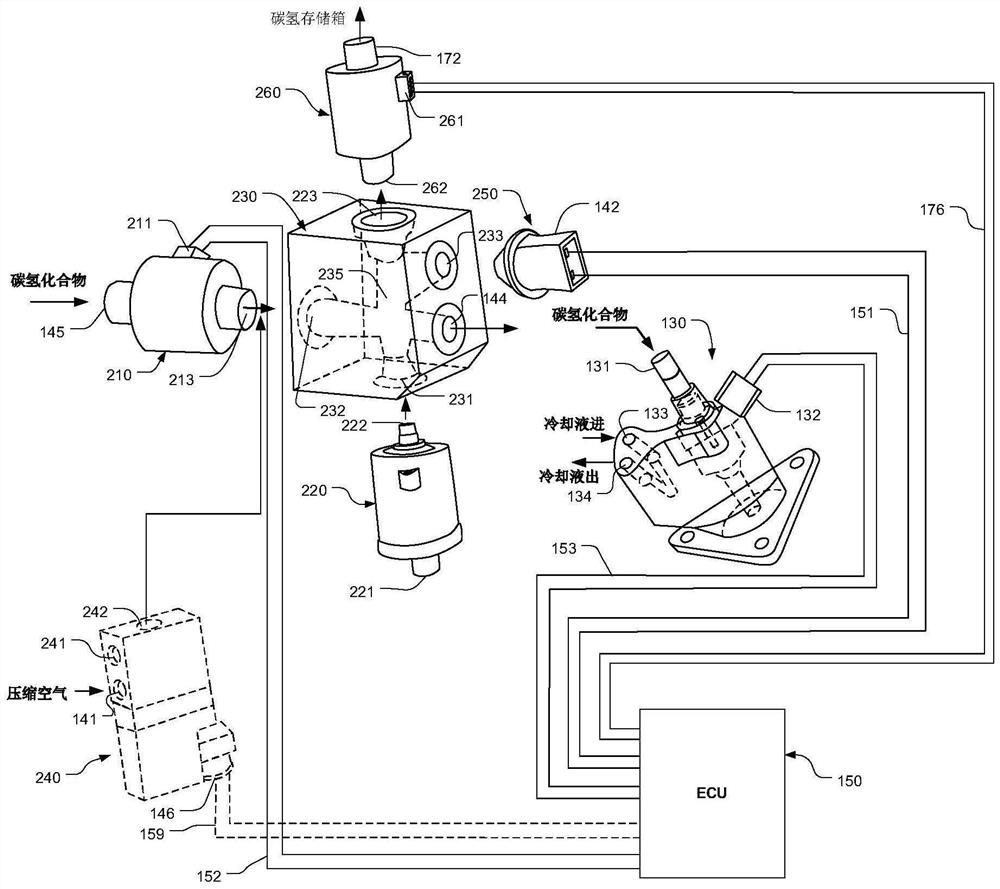

[0044] Such as figure 1 As shown, an exhaust gas treatment system of the present invention includes an internal combustion engine 100, a catalyst conversion device 160 located at the exhaust outlet of the exhaust manifold 101 of the internal combustion engine, and the catalyst conversion device 160 includes an exhaust passage 166, a tapered constriction 165, DOC161, DPF162, An external hydrocarbon injection device, a first temperature sensor 163, a first differential pressure sensor 164, a second temperature sensor 167, a third temperature sensor 169, a second differential pressure sensor 168, and a controller 150. The exhaust gas passage 166, the tapered neck 165, the DOC161 and the DPF162 are arranged along the exhaust gas outlet direction. The exhaust gas generated in the internal combustion engine 100 enters the exhaust gas passage 166 through the exhaust ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com