Tail gas treating device for lampblack exhauster

A technology for exhaust gas treatment and air extractor, which is applied in the direction of oil fume removal, application, household stove, etc., can solve the problems of high maintenance cost, low treatment efficiency, air pollution easily, etc., and achieves the effect of simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

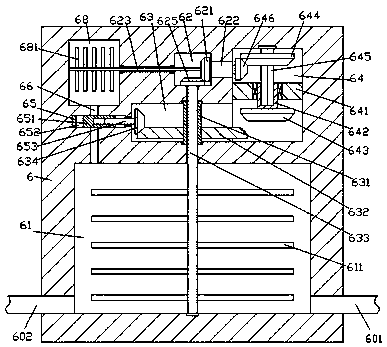

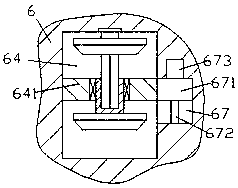

[0014] Combine below Figure 1-3 The present invention will be described in detail.

[0015] refer to Figure 1-3 , according to an embodiment of the present invention, an exhaust gas treatment device for a fume extractor, including a processing base 6, a first processing chamber 61 is arranged inside the processing base 6, and the right inner wall of the first processing chamber 61 An air inlet pipe 601 is arranged inside, an air outlet pipe 602 is arranged in the inner wall on the left side of the first processing chamber 601, and a first hole 62 is arranged in the processing base 6 on the upper side of the first processing chamber 61, so that A second hole 63 is provided in the processing seat 6 between the first hole 62 and the first processing chamber 61, and a second hole 63 is provided in the processing seat 6 on the left side of the first hole 62. There is a second processing cavity 68, and the first sliding cavity 64 is arranged in the processing base 6 on the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com