Air conditioner fan blade bearing seat assembly and air conditioner indoor unit

A technology for air-conditioning indoor units and bearing housings, which is applied to bearing elements, rigid supports of bearing components, air-conditioning systems, etc., and can solve problems such as fan blade bearing housings falling out, fan blade bearing housings not being installed in place, increased costs, and processing complexity, etc. problem, to avoid the effect of prolapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

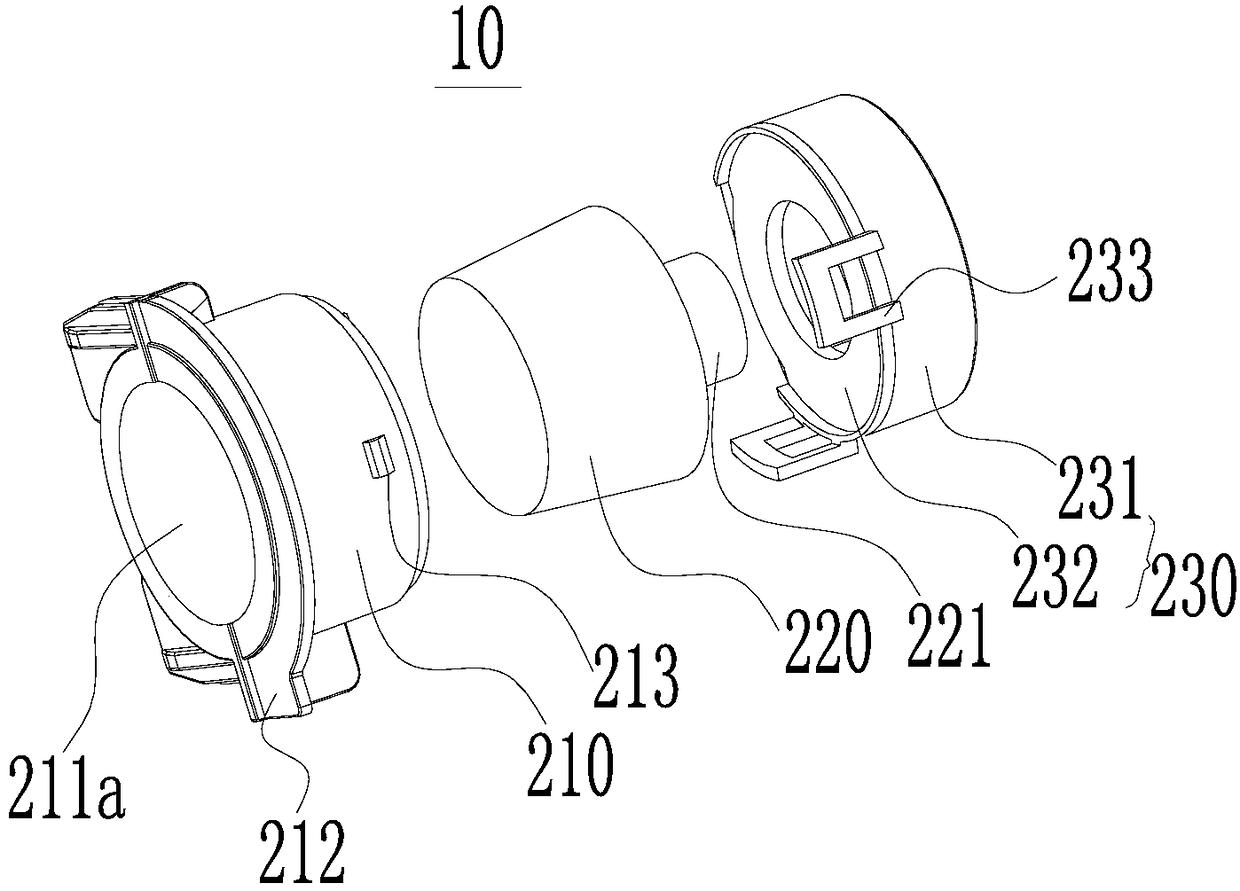

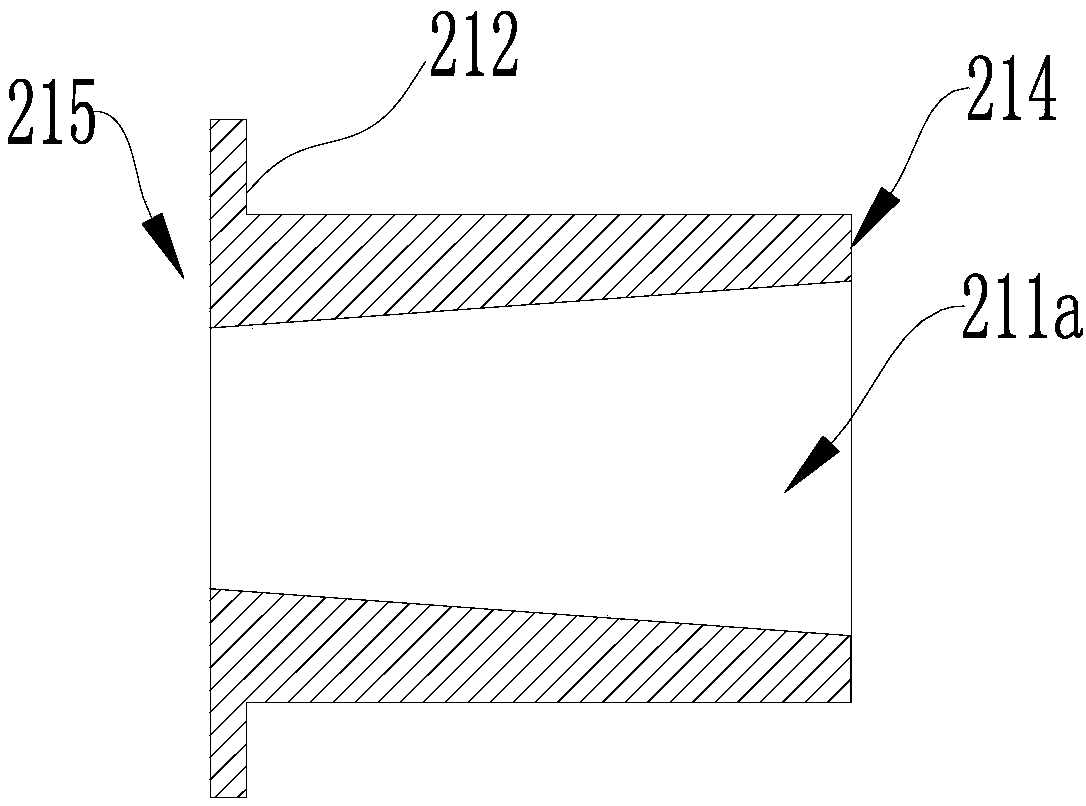

[0033] Such as figure 1 As shown, the present embodiment provides an air conditioner fan blade bearing seat assembly 10, which includes a bearing seat 210, a fan blade bearing 220 and a bearing fixing member 230, see figure 2 , figure 2 Shows the cross-sectional structural view of the bearing seat 210 in this embodiment, wherein the bearing seat 210 has an opposite first end 214 and a second end 215, the bearing seat 210 is provided with a mounting hole 211a for installing the fan blade bearing 220, and the mounting hole 211a penetrates through the bearing seat 210 along the direction from the first end 214 to the second end 215 . The axis of the installation hole 211 a coincides with the axis of the bearing housing 210 , wherein the installation hole 211 a is used for installing or assembling the blade bearing 220 .

[0034] At least a part of the installation hole 211a is a variable diameter section, where the variable diameter section refers to the extension direction o...

Embodiment 2

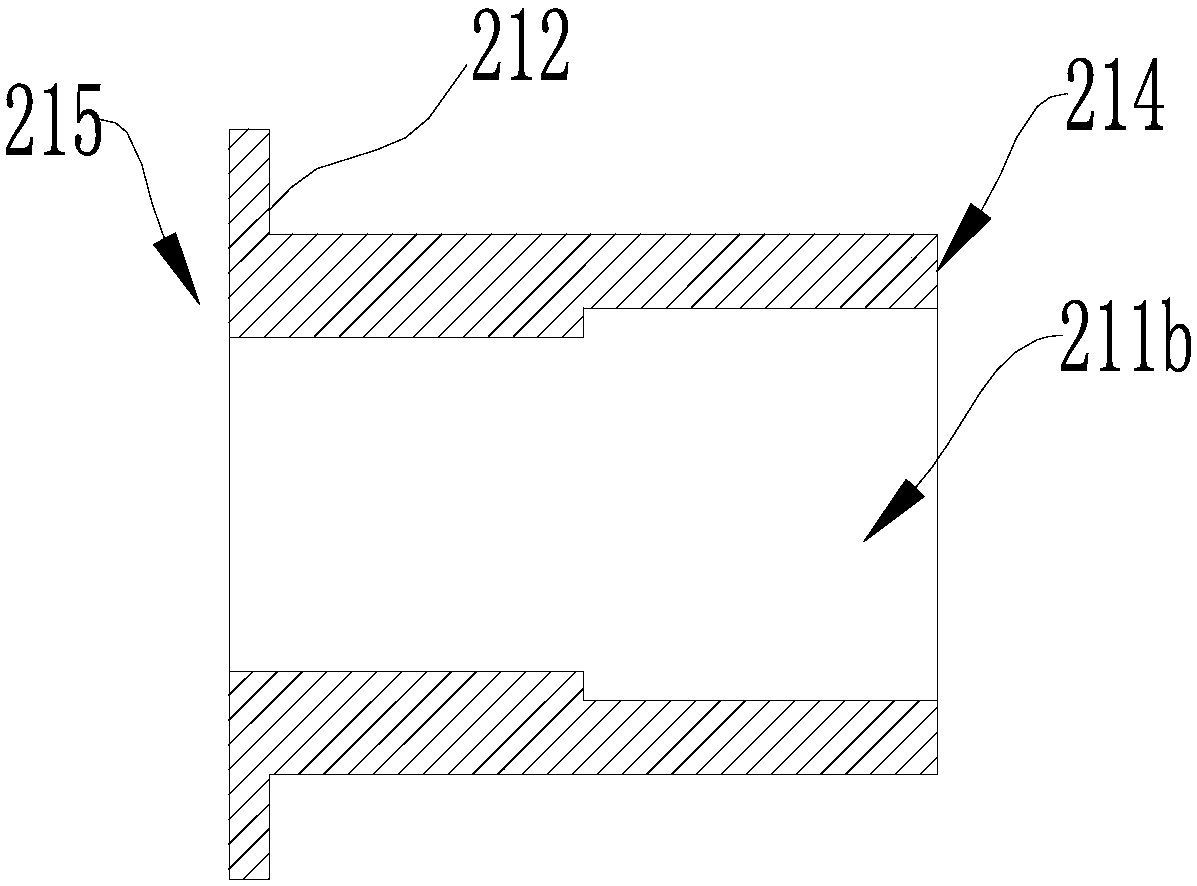

[0046] Such as image 3 As shown, this embodiment provides an air conditioner fan bearing seat assembly 10, which is different from the air conditioner fan bearing seat assembly 10 provided in Embodiment 1 in that the bearing seat 210 is provided with a mounting hole 211b, wherein the mounting hole 211b The structural arrangement of the reducing section is different from that of the mounting hole 211a in Embodiment 1. Correspondingly, the structure of the blade bearing 220 matched with the mounting hole 211b is matched with the structure of the bearing housing 210 in this embodiment.

[0047] Specifically, see image 3 , in this embodiment, the mounting hole 211a on the bearing seat 210 has a diameter reducing section, which is located in the middle of the mounting hole 211a, and the diameter reducing section only includes a part of the mounting hole 211b, and the diameter reducing section The inner diameter is a sudden design, that is, the installation hole 211b is a stepped...

Embodiment 3

[0052] refer to Figure 4 This embodiment provides an air conditioner indoor unit, including the fan blade 100, the base 110 and the air conditioner fan blade bearing seat assembly 10 of Embodiment 1, wherein the base 110 is a part of the air conditioner indoor unit for installation on a wall. In the air-conditioning indoor unit in this embodiment, the bearing seat 210 is installed on the base 110, and the small end of the variable diameter section of the installation hole 211a is set toward the side of the fan blade 100, and the large end of the variable diameter section of the installation hole 211a faces the base 110 Outer setting. The fan blade bearing 220 is installed in the installation hole 211a, and the fan blade 100 is installed on the fan blade bearing 220 .

[0053] Wherein the fan blade bearing 220 is matched with the installation hole 211 a of the bearing seat 210 .

[0054] read on Figure 5 with Image 6 , the second abutting portion 232 of the bearing fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com