Vibration tests and methods for simulating adhesive motion on elastic planes in microgravity

A technology that simulates microgravity and vibration testing. It is applied in vibration testing, machine/structural component testing, and measuring devices. It can solve problems such as vibration testing and its control methods that have not yet been reported, improve experimental testing performance, and facilitate the realization of motion. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

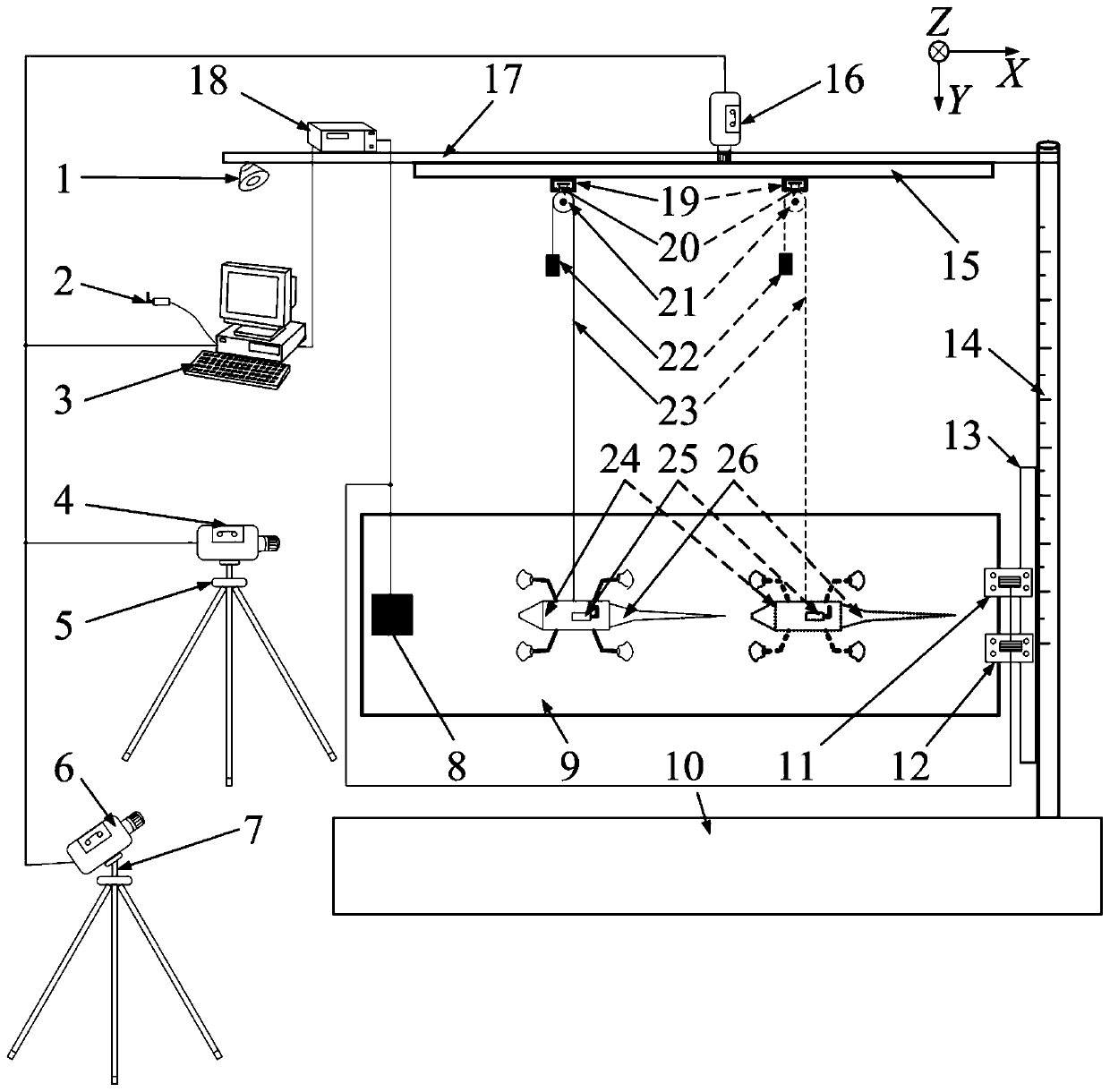

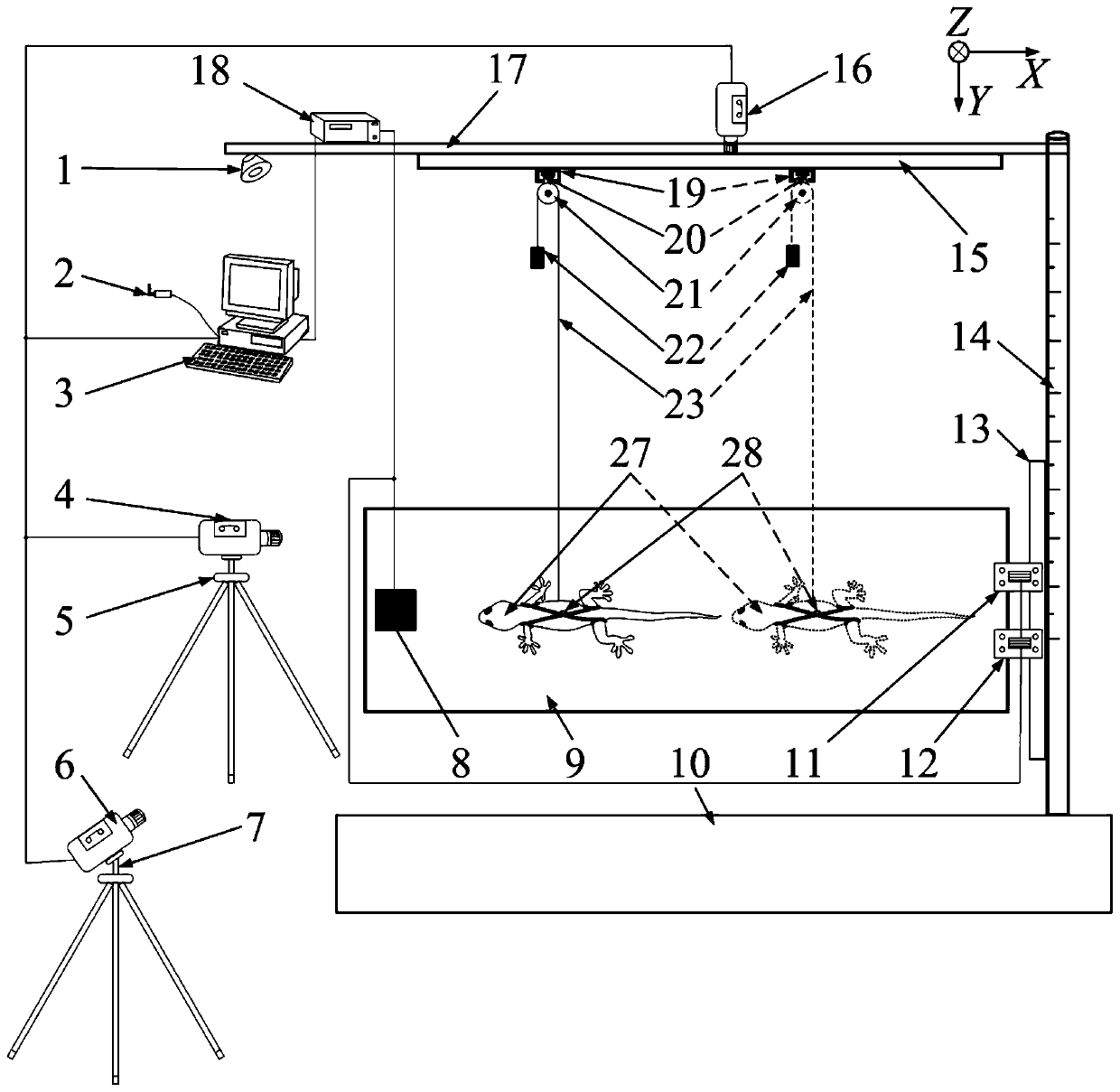

[0021] combine figure 1, this embodiment is a vibration test and control method for simulating the adhesion motion on an elastic plane under microgravity, including a light source 1, a host computer wireless communication module 2, a computer control terminal 3, an X-direction high-speed camera 4, and an X-direction tripod 5 , Z-direction high-speed camera 6, Z-direction tripod 7, micro-inertial navigation module 8, elastic plate 9, platform base 10, Y-axis No. A torque sensor 11, Y-axis No. B torque sensor 12, connecting plate 13, support Scale rod 14, X-direction moving slide rail groove 15, Y-direction high-speed camera 16, supporting top plate 17, sensor data acquisition system 18, Z-direction moving slide rail groove 19, Z-direction moving slide rail block 20, fixed pulley 21, distribution Heavy object 22, string 23, legged robot main body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com