Sequential batch test piece introduction device for two-box thermal shock experiment box

A leading-in device and thermal shock technology, which is applied in the field of sequentially leading-in devices for batch test pieces, can solve problems such as poor reliability, difficulty in realizing a large-scale adjustment of speed, and inability to ensure the consistency of the test environment, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

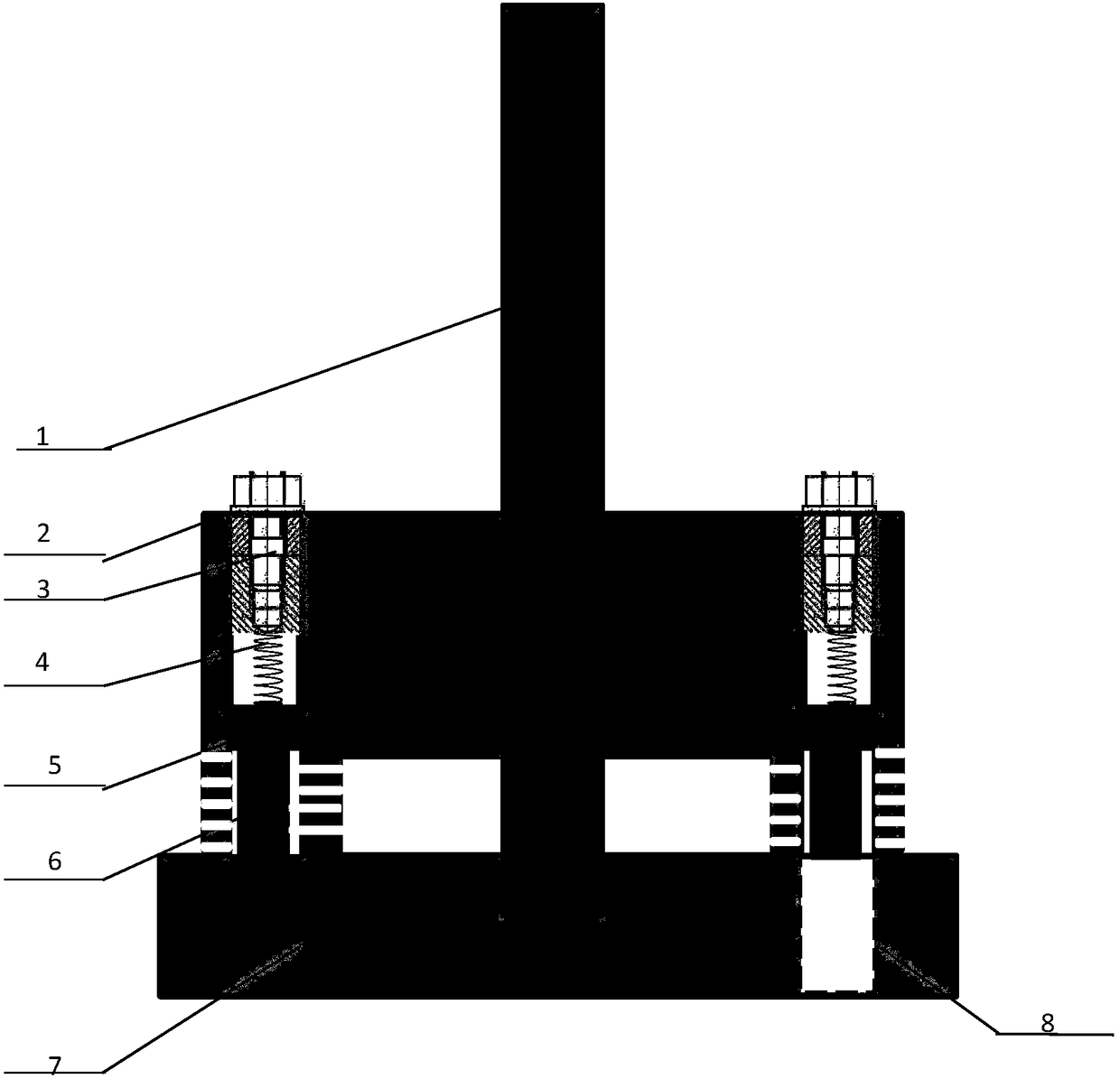

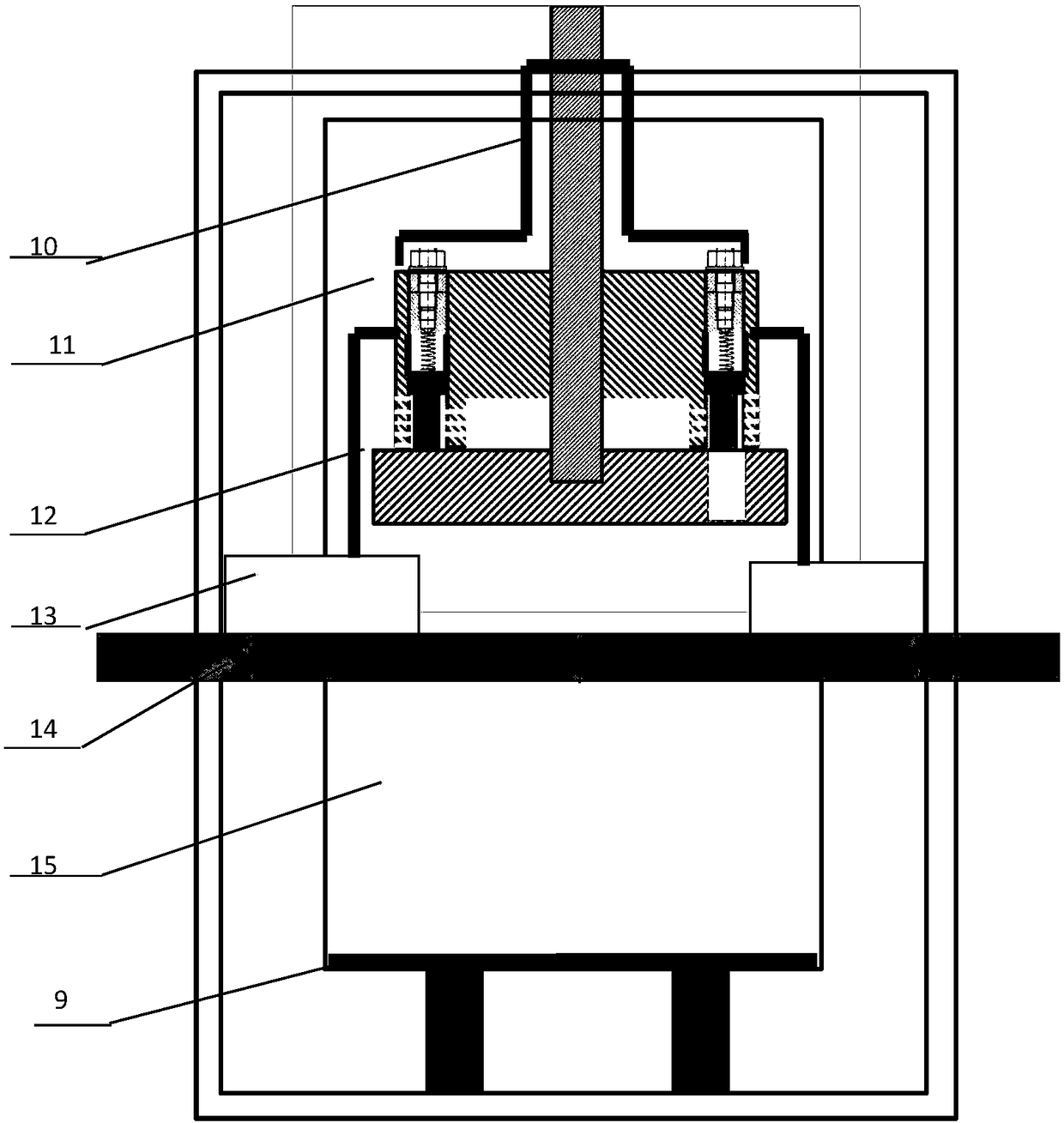

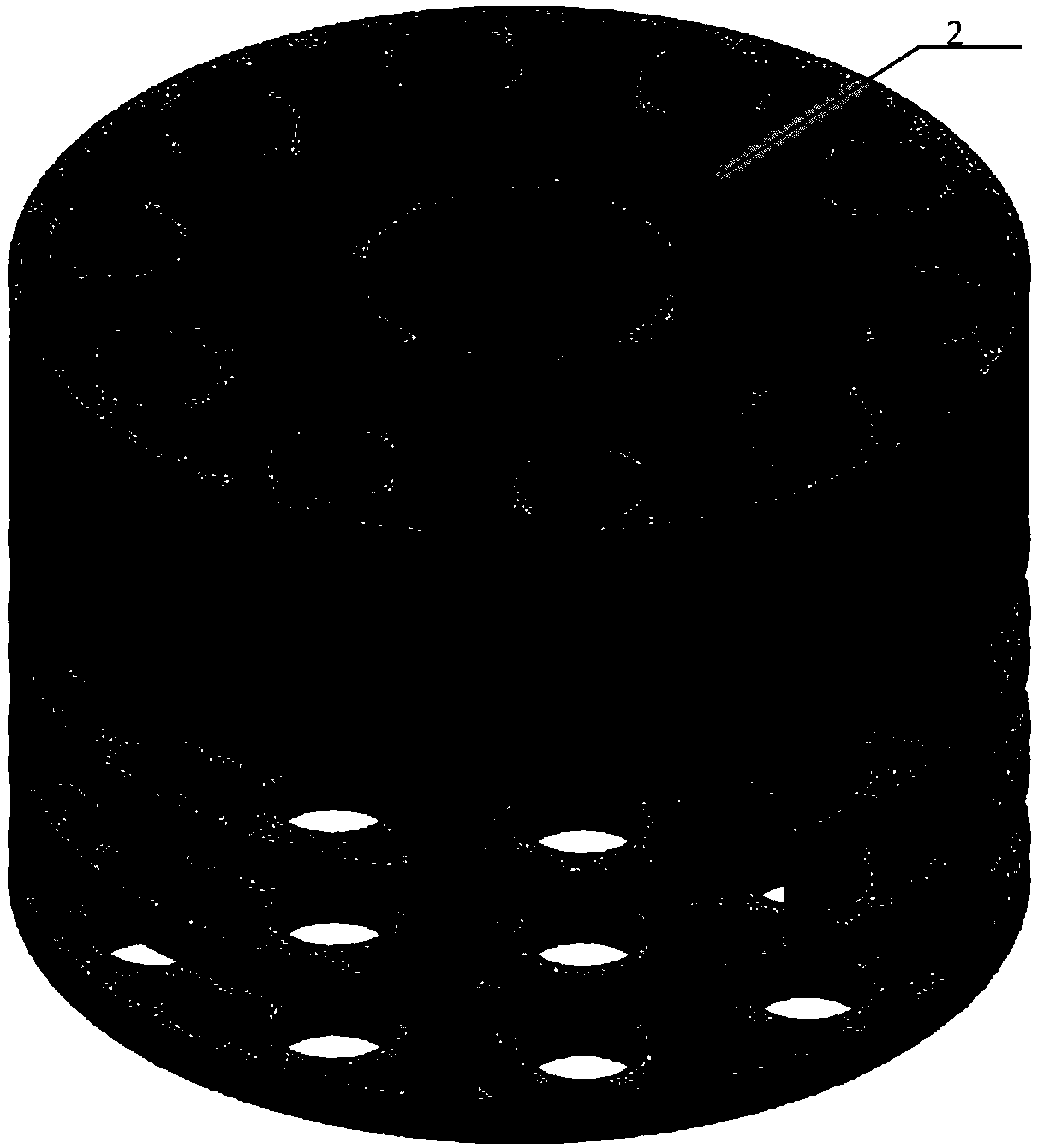

[0023] Such as figure 1 with figure 2 As shown, the present invention includes a rotating shaft 1 , a specimen holding disc 2 and a baffle plate 7 with holes. A graphite sleeve 10 is sheathed on the specimen holding disc 2, and a heat insulation zone is formed between the two. One end of the rotating shaft 1 penetrates through the specimen holding disc 2 and the graphite sleeve 10, and is embedded in the perforated baffle 7 to connect with it, and the other end extends out of the high temperature chamber and is rotatable. There are a group of holes evenly distributed in the circumferential direction on the specimen holding plate 2, and bolts 3, springs 4, heat insulation protection structures 5, and specimens 6 are installed in each hole in sequence from top to bottom, corresponding to the vertical height area of the specimen. The test piece holding disc 2 is hollowed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com