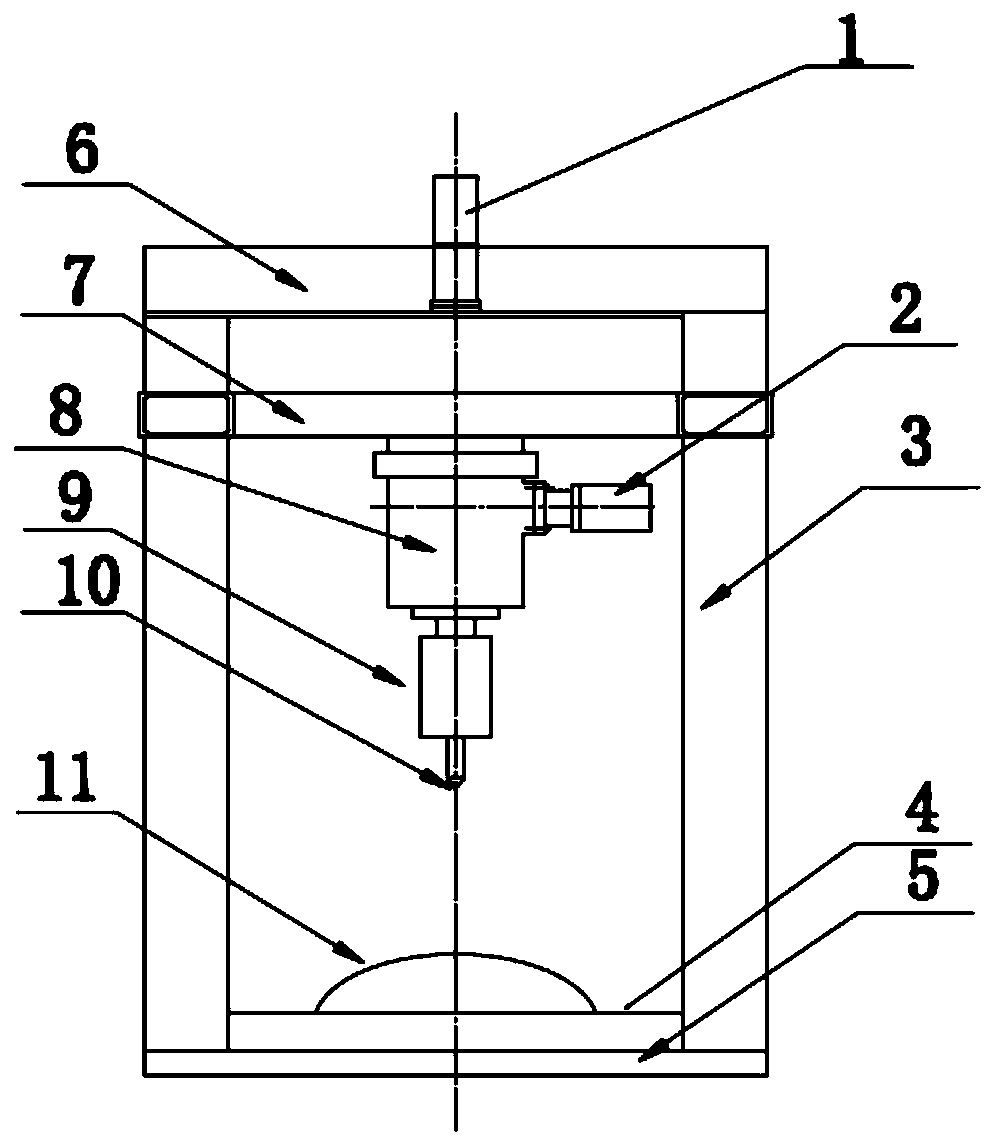

Dynamic dent resistance measuring device of sheet metal

A technology of thin metal plates and measuring devices, which is applied in the direction of measuring devices, strength characteristics, and the use of stable tension/pressure to test the strength of materials, etc., can solve the problem of inaccurate measurement of dynamic anti-dent performance, and achieve the effect of constant speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

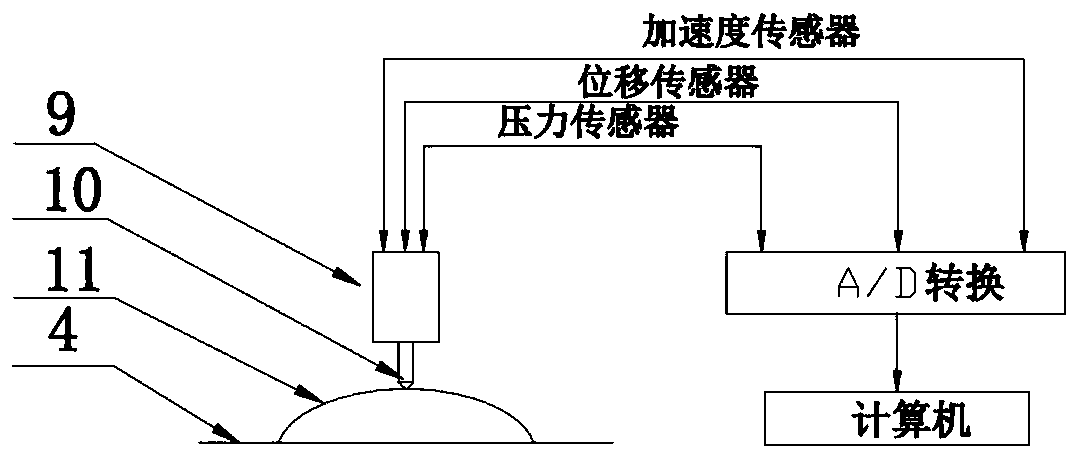

Method used

Image

Examples

Embodiment 1

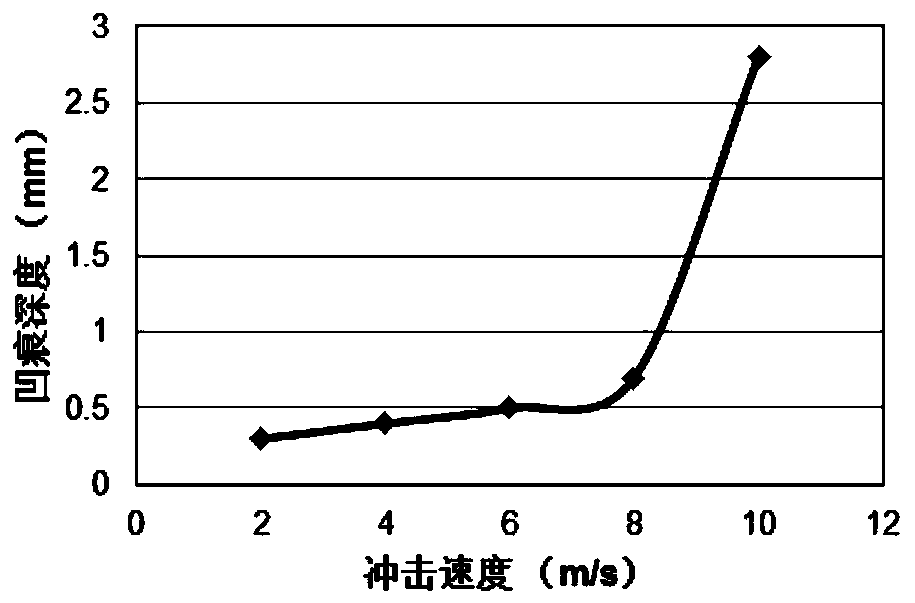

[0066] The sample prepared with DX51D+Z cold-rolled steel plate was fixed on the test bench through the blank holder, and the distance between the moving beam and the sample was adjusted to 0.5m. The test parameters were adjusted by the equipment operating software, and the indenter speeds were set to 2m / s, 4m / s, 6m / s, 8m / s, and 10m / s, respectively. At the beginning of the test, the sensor records the pressure, acceleration, displacement, and contact time data during the test. Through data processing, the relationship between impact velocity and dent depth is obtained, such as image 3 shown.

Embodiment 2

[0068] The samples made of AA6016 aluminum alloy with three thicknesses of 1.0mm, 1.5mm and 2.0mm were fixed on the test bench, and the distance between the moving beam and the sample was adjusted to 0.5m. The test parameters were adjusted by the equipment operating software, and the indenter speed was set to 4 m / s. At the beginning of the test, the sensor records the pressure, acceleration, displacement, and contact time data during the test. Through data processing, the dynamic load energy-dent depth relationship curve is obtained, such as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com