A batch-type cooling thermal shock test device for ultra-high temperature ceramic materials

A technology for ultra-high temperature ceramics and impact testing, applied in measuring devices, analytical materials, instruments, etc., can solve problems such as poor reliability, low precision of characterization results, and influence on mechanical test results, etc., to achieve good thermal shock environment consistency, initial The speed is controllable and the effect of avoiding mechanical shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

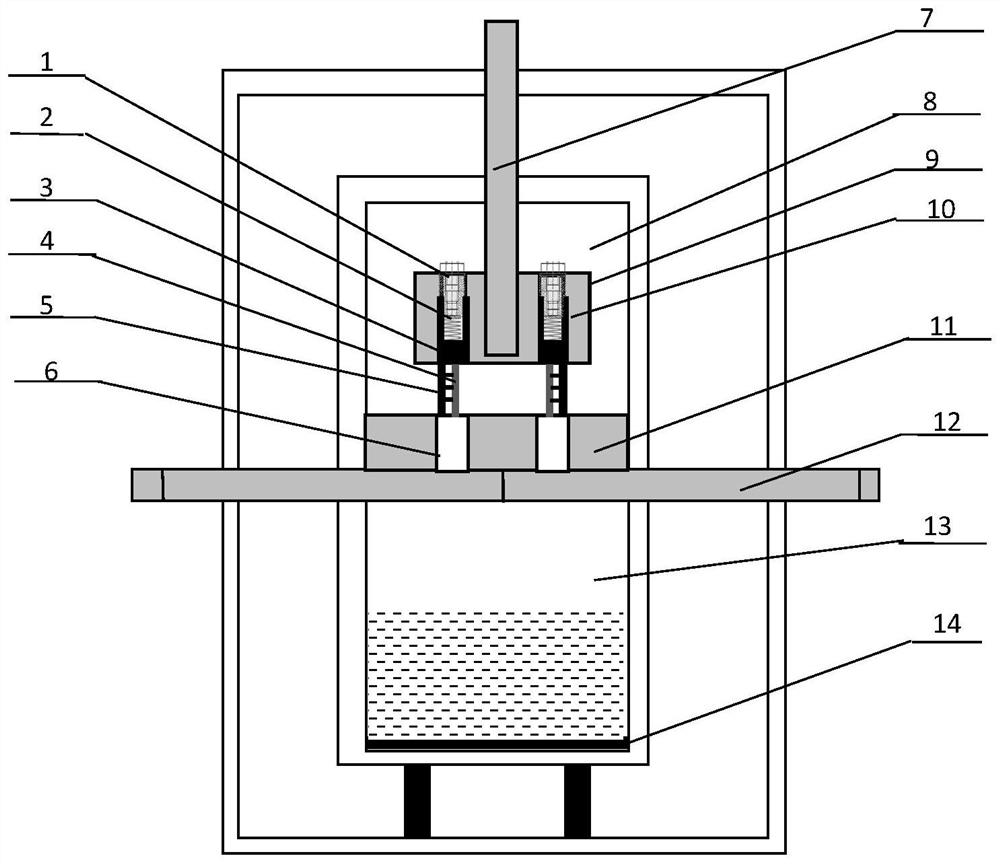

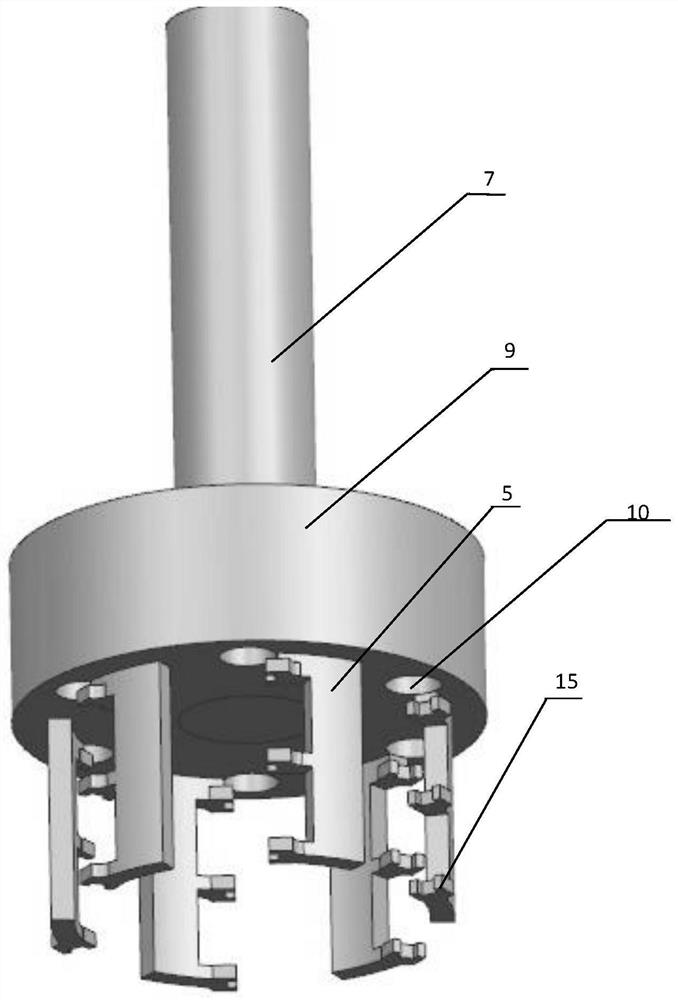

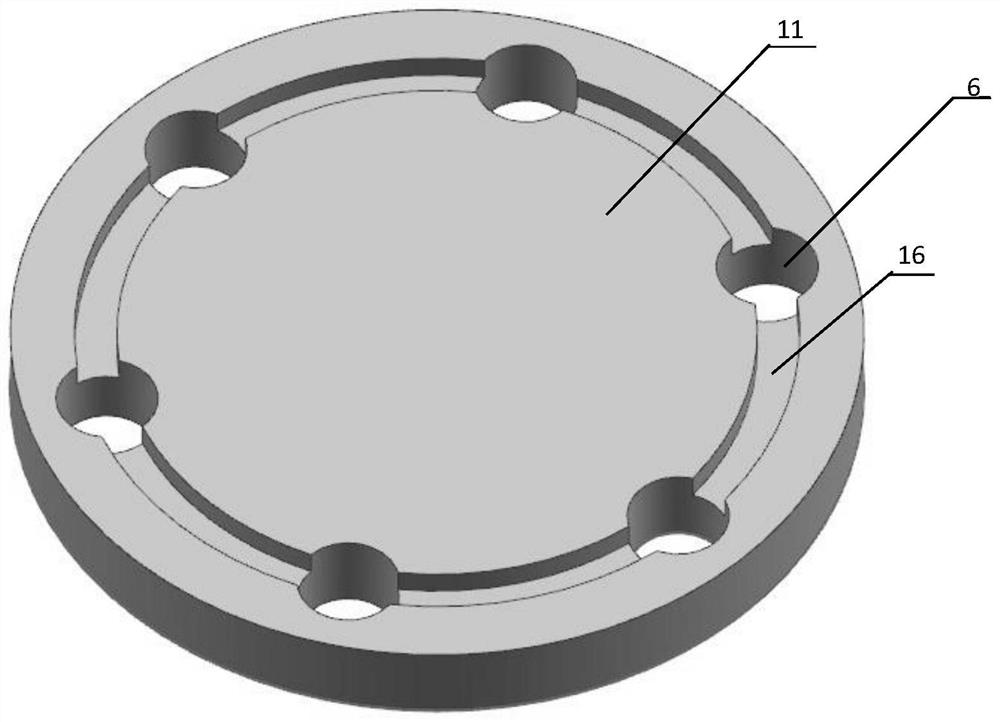

[0022] like figure 1 and figure 2 As shown, the present invention includes a high temperature chamber (8), a cooling chamber (13) and a hatch (12), and the hatch (12) separates the two chambers. The specimen clamping disc (9) is connected with the rotating shaft (7), and the rotating shaft (7) extends out of the high temperature chamber (8) and is rotatable. The perforated baffle (11) is installed above the closed hatch (12). There are a group of upper holes (10) with equal circumferential spacing in the disk of the specimen clamping disk (9), and each hole is in order from bottom to top with heat insulation protection structure (3), high temperature resistant spring (2), high temperature resistant bolt (1). There is an arm-type structure test piece booster (5) at the bottom of the test piece holding disc (9), and the groove (15) on the test piece booster (5) can fix t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com