Two-segment type positioning device for tapping machine

A positioning device and two-stage technology, applied in the field of tapping machines, can solve problems such as wear of nut parts and affect the quality of nuts, and achieve the effect of reducing wear and improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

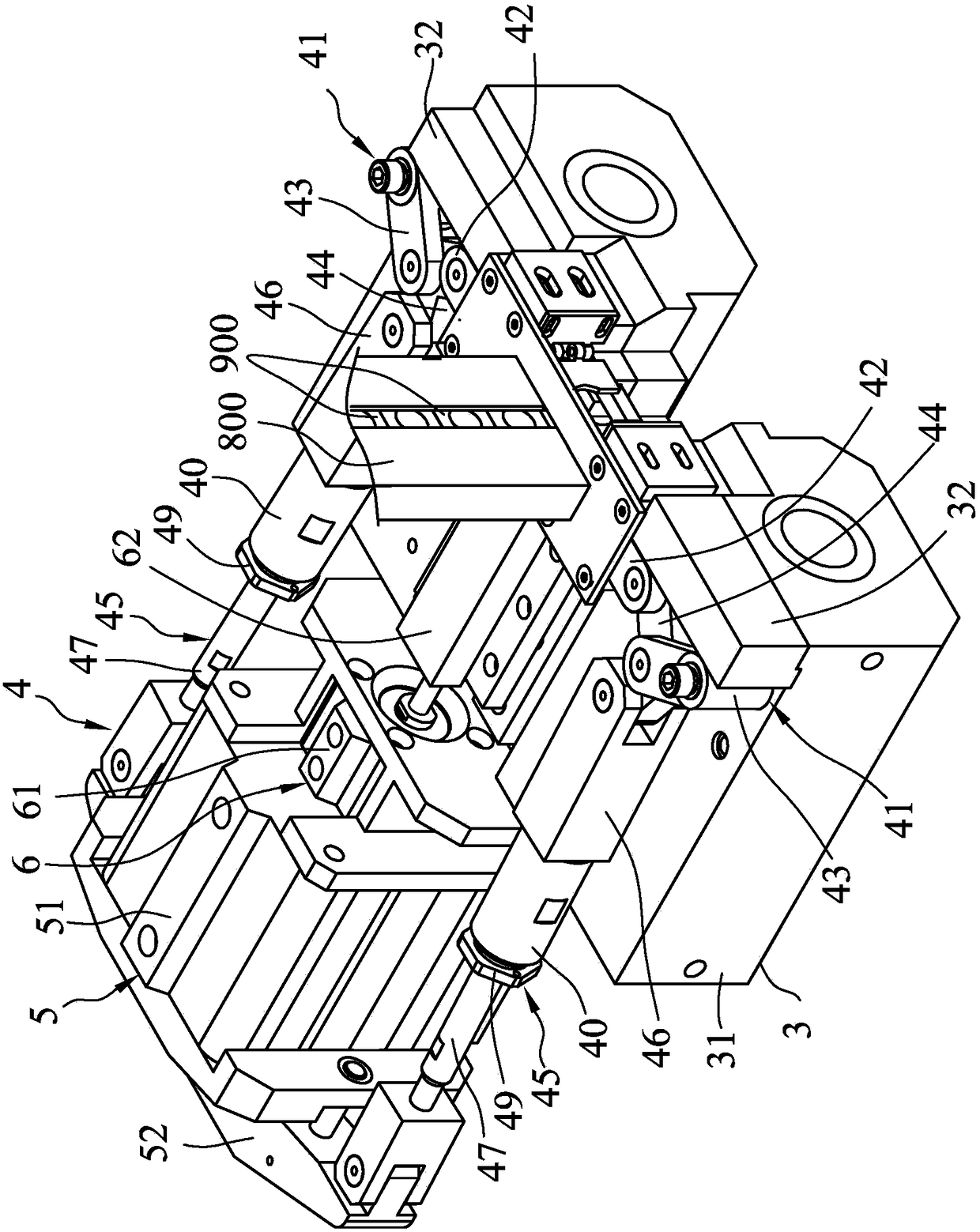

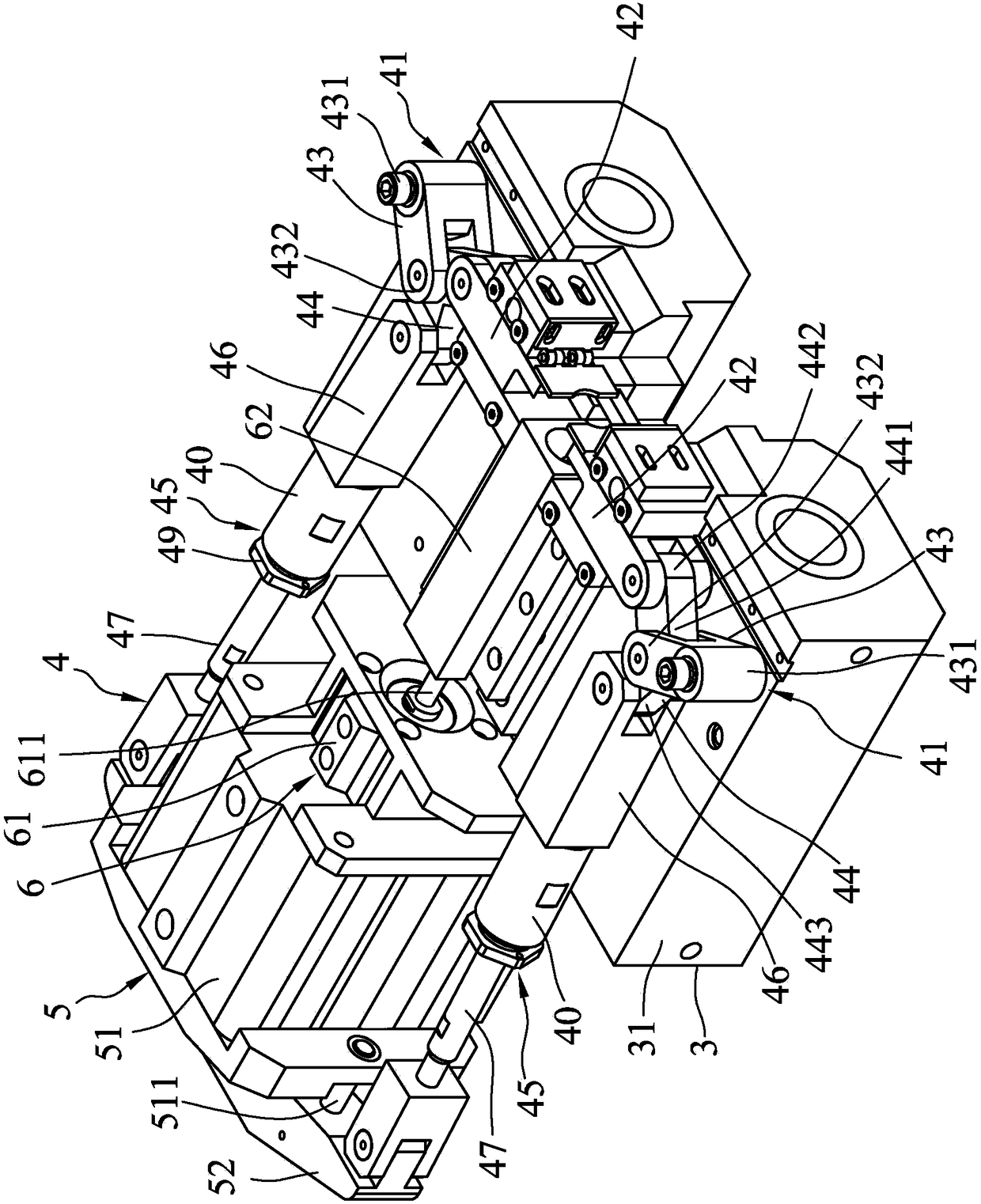

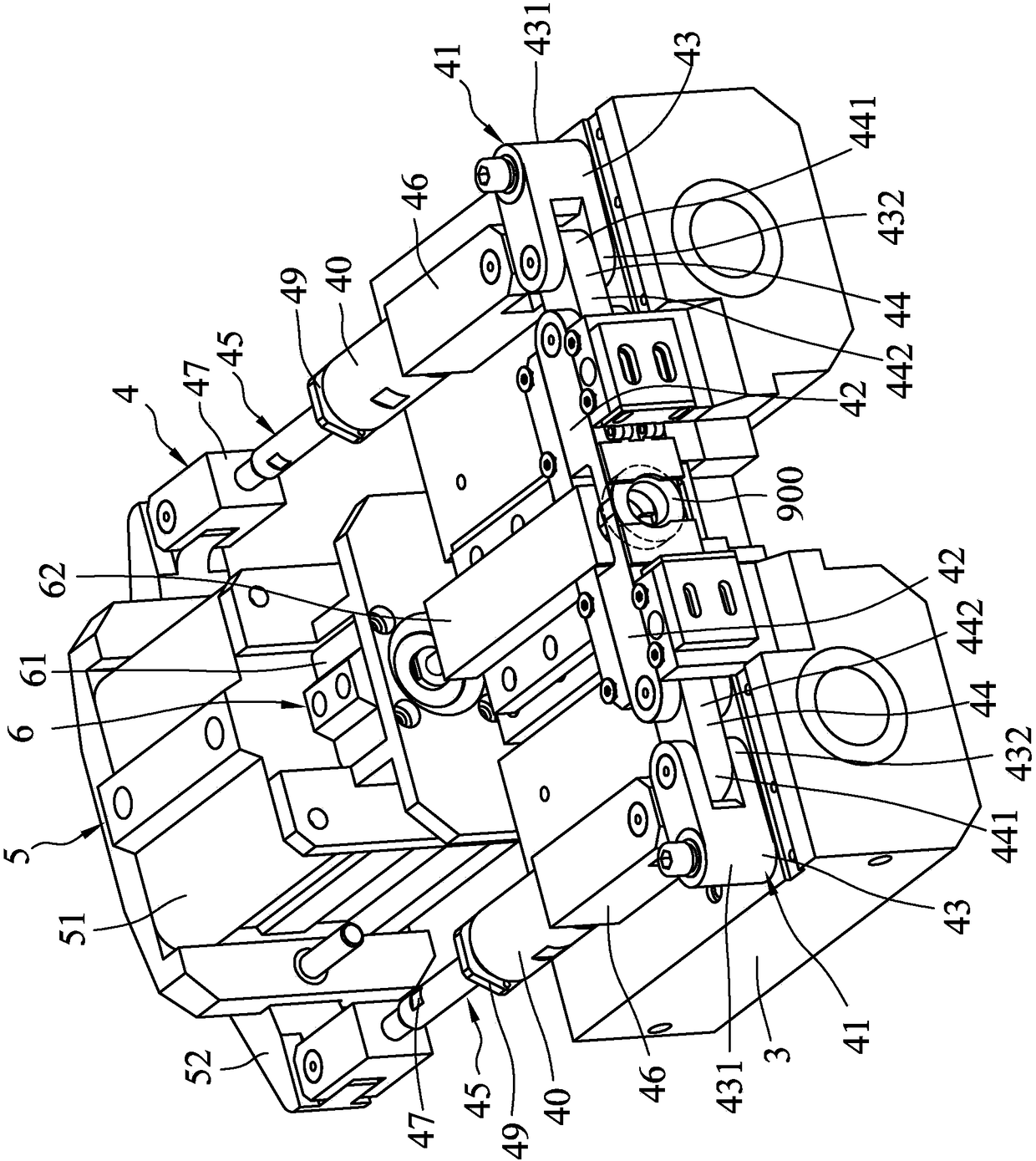

[0023] refer to figure 1 , 2 3. The embodiment of the two-stage positioning device of the tapping machine of the present invention is suitable for use with a blanking machine 800 for conveying and supplying nut parts 900 to be tapped, and can release the blanking machine 800 A nut part 900 is clamped for a tapping part (not shown) to carry out tapping operations. The two-stage positioning device includes a base 3, a clamp mechanism 4 mounted on the base 3, a clamping drive mechanism 5 mounted on the base 3 and connected to the clamp mechanism 4, and a The rectifying mechanism 6 installed on the base 3 and used for rectifying the nut part 900 clamped by the clamp mechanism 4 to be processed.

[0024] The base 3 has a seat portion 31 , and two stop portions 32 extending from left to right and protruding from the front side of the top surface of the seat portion 31 at intervals.

[0025] The clamping mechanism 4 is installed on the seat body 31, and can be driven by the clampi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap