An oscillating conveyor belt for cooling fins

A technology for conveyor belts and heat sinks, applied in the field of conveyor belts, can solve the problems of falling damage to heat sinks, inconvenient stacking and collection of heat sinks, unfavorable heat sink processing operations, etc., to achieve low equipment costs and prevent bump damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

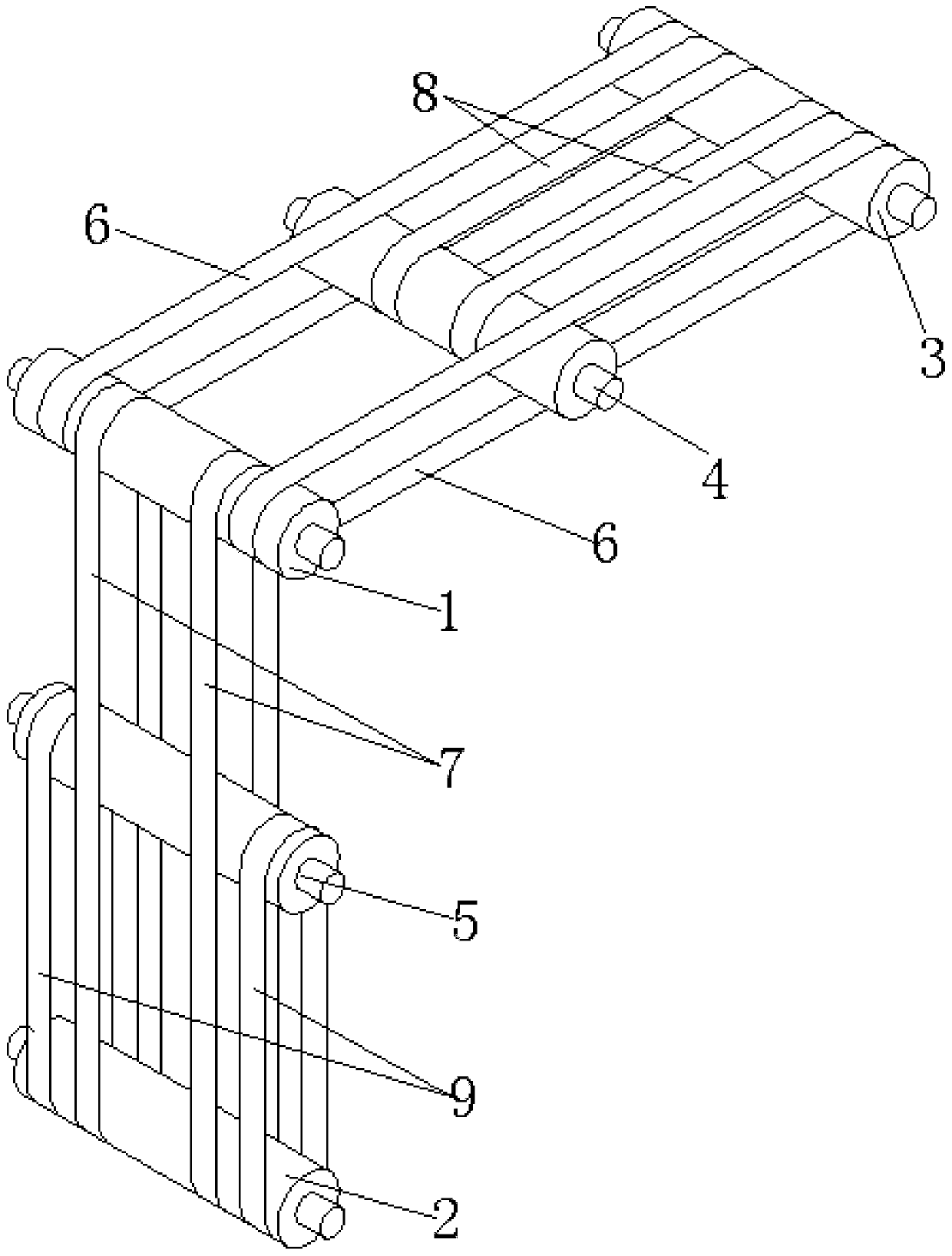

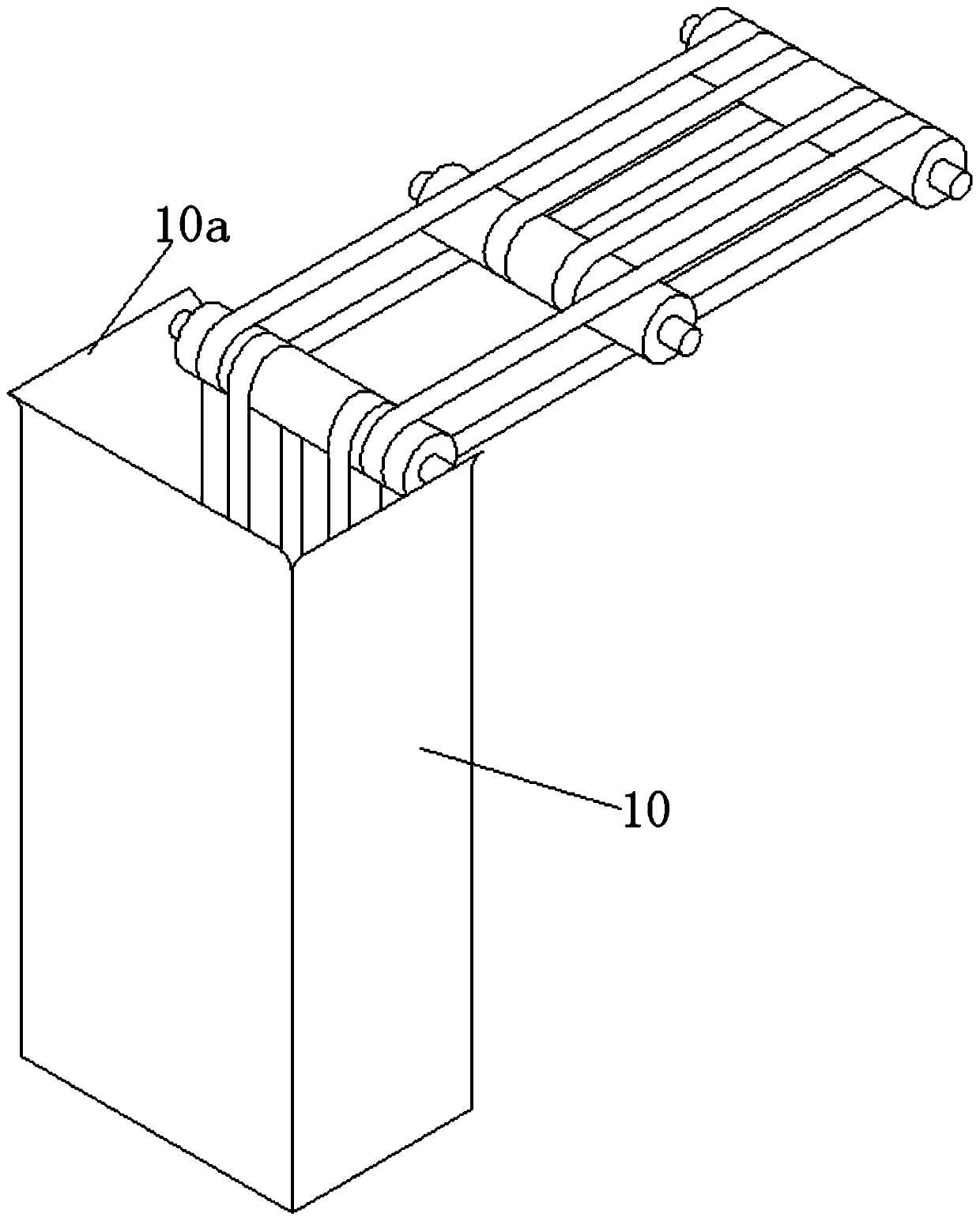

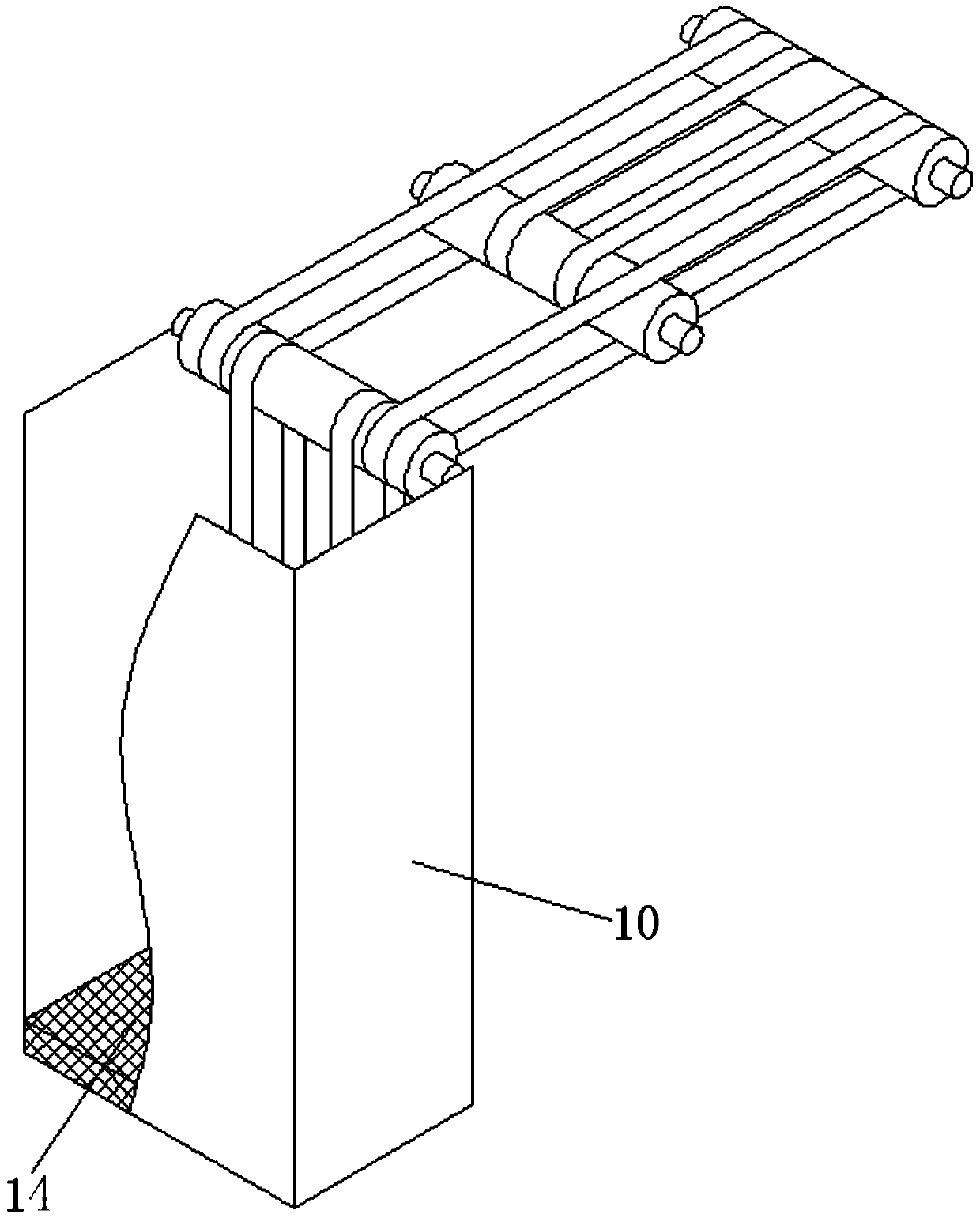

[0034] In order to achieve the purpose of the present invention, a swing conveyor belt for heat sinks includes: a horizontal conveyor belt with a first conveyor belt 6 connecting the power roller 1 and a horizontal roller 3, and the first conveyor belt 6 is transmitted in the horizontal direction; the swing conveyor belt is equipped with a connecting The second conveyor belt 5 of the power roller 1 and the swing roller 2; the blanking box 10 is arranged in parallel with the connection direction of the power roller 1 and the swing roller 2, the blanking box 10 is connected with a swing motor, and the blanking box 10 is equipped with a heat sink for accommodating cavity; the swing roller is fixedly connected with the blanking box, the swing motor drives the blanking box, the swing roller swings along the axis of the power roller itself, the blanking box and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com