Bed body with horizontal uplift and fall of bed plate

A technology that flat rises and falls flat, and the bed board is applied in the field of furniture. It can solve the problems of destroying the bed body, difficulty in handling, and inability to lift the bed board, and achieves the effects of reducing the falling speed, uniform development degree, and saving finishing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

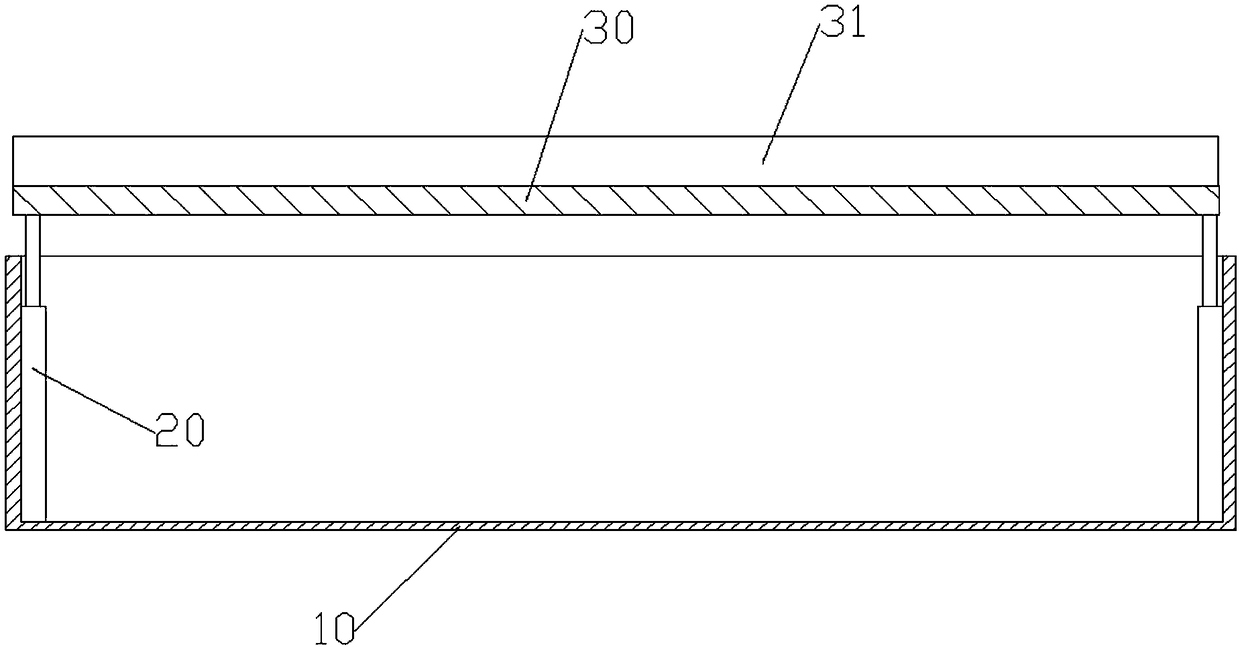

[0042] Such as figure 1 As shown, the present embodiment provides a bed body with a bed that rises and falls flat, including: a bed box 10 , a bed board 30 and a lifting module 20 .

[0043] The inside of the bed box 10 is provided with an accommodating space, and an opening is provided on the top; at least two lifting modules 20 that are set up side by side at intervals are respectively arranged on the opposite sides of the bed box 10; It is installed at the opening of the bed box 10 in a horizontally raised or lowered manner.

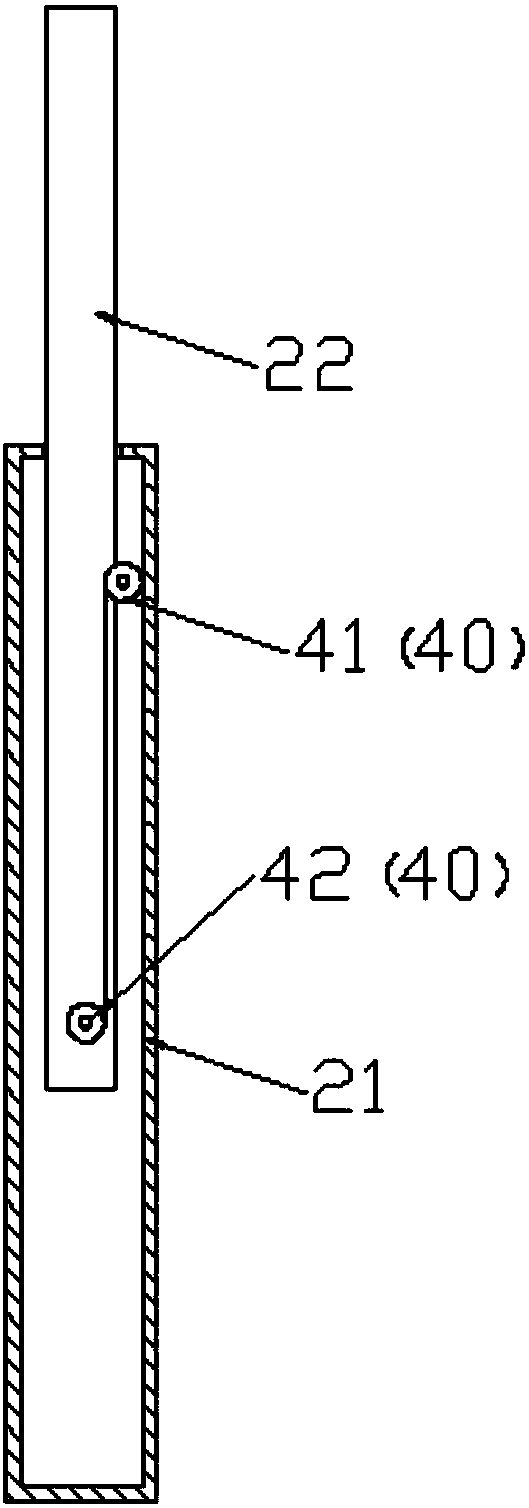

[0044] Such as figure 2 As shown, the lifting module 20 includes a cylinder body 21 , a lifting column 22 and a winding spring 40 .

[0045] The cylinder body 21 is set upright and leans against the inner side of the side plate of the bed box 10; a chute is arranged in the cylinder body 21 along the height direction, and an outlet connecting the inside and outside of the cylinder body 21 is arranged above the cylinder body 21; the lifting column The...

Embodiment 2

[0060] This embodiment is a more optimized improvement made on the basis of Embodiment 1, and the specific improvements are as follows:

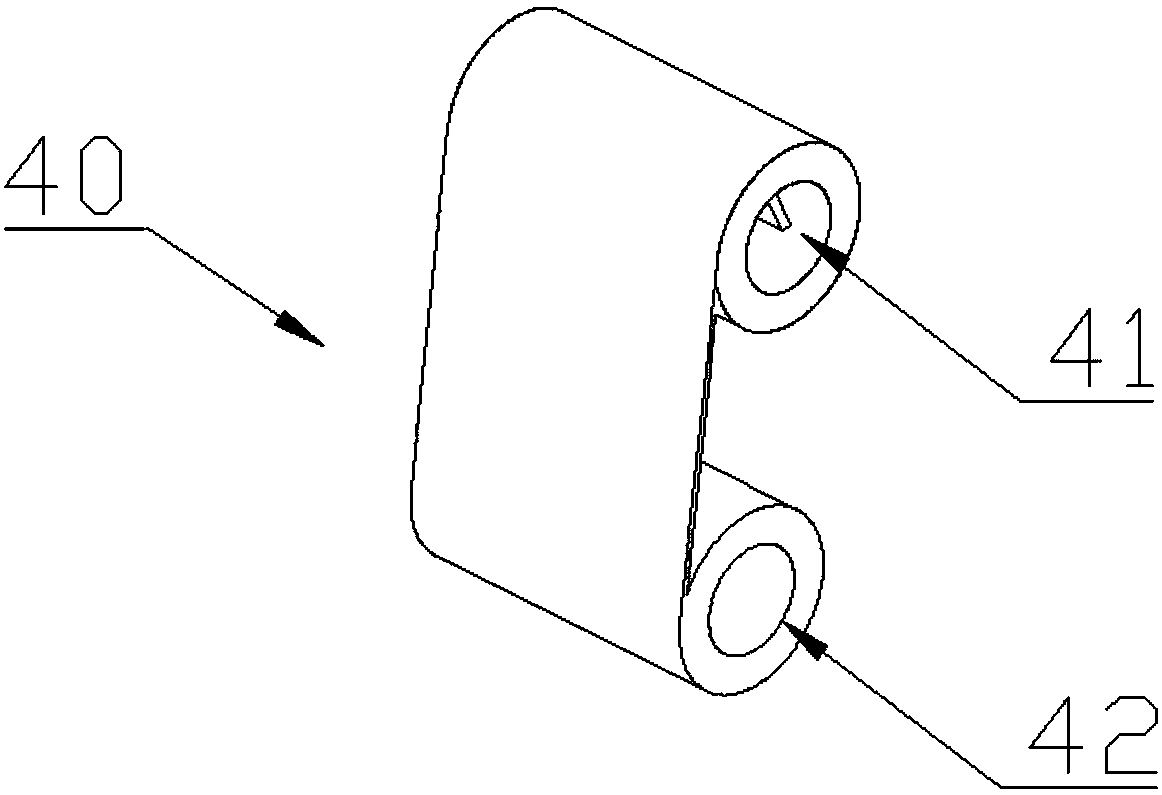

[0061] The first reel part 41 is rotatably arranged on the cylinder body 21 through a rotating shaft (not shown); the first reel part 41 is sleeved on the rotating shaft, and the first The reel portion 41 is relatively fixedly connected to the rotating shaft; the rotating shaft is rotatably arranged on the installation hole of the cylinder 21, and a locking mechanism (not shown) for locking the rotating shaft is arranged between the rotating shaft and the cylinder 21. show).

[0062] The first roll part 41 is rolled up or rolled up by rotating the rotating shaft, and the second roll part 42 is rolled up or rolled up synchronously under the action of its own spring force. Decrease or increase, and then the support force provided by the coil spring 40 decreases or increases accordingly, which is used to meet the support requirements of bed bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com