Tire glue piece rolling and turning-over device

A technology of flipping device and film, applied in the field of tire production, can solve problems such as troublesome film connection, peeling of film and rubber strip, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

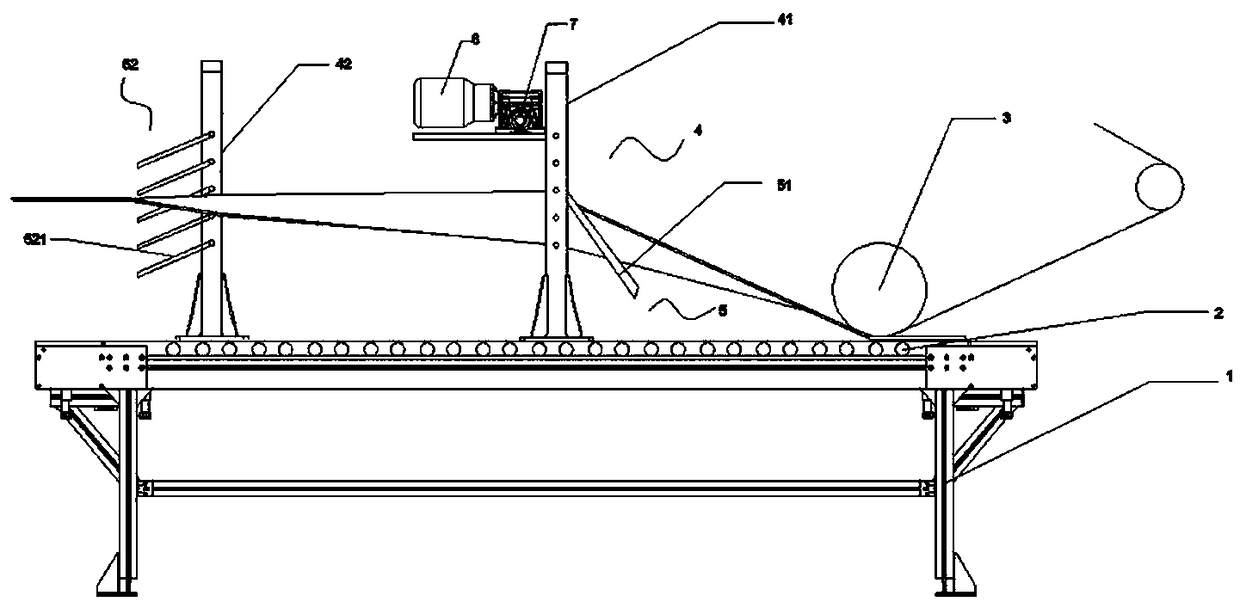

[0017] like figure 1 The shown tire film calendering and turning device includes a conveying frame 1 , a rubber-guiding conveying roller 2 , a bead roller 3 , a film supporting frame 4 and a film turning roller group 5 .

[0018] The conveyor frame 1 is arranged horizontally; the rubber guide conveyor rollers 2 are arranged on the conveyor frame 1 at equal intervals along the extension direction of the conveyor frame 1; Above the rubber conveying roller 2, there is a gap between the beading roller plate 3 and the rubber guiding conveying roller 2 to accommodate the passage of the film, and the beading roller plate 3 is provided with a rubber strip.

[0019] The film support frame 4 has a pair including a first film support frame 41 and a second film support frame 42, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com