Horizontal well open hole screen casing damaging detection tubular column

A damage detection, horizontal well technology, applied in wellbore/well components, surveying, earthmoving, etc., to ensure continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

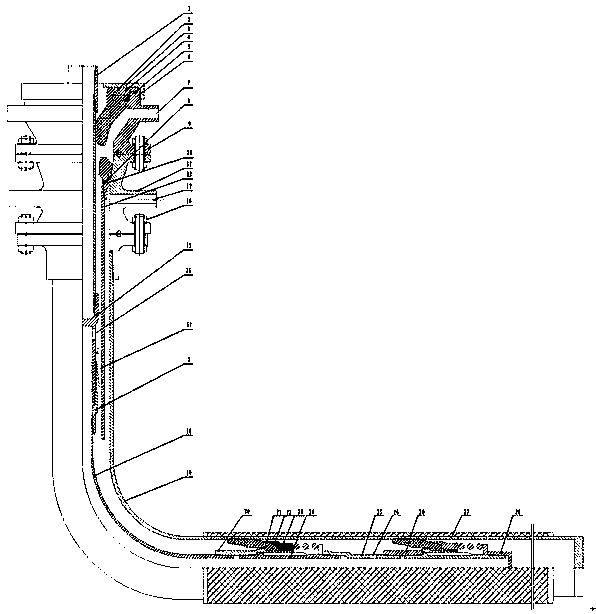

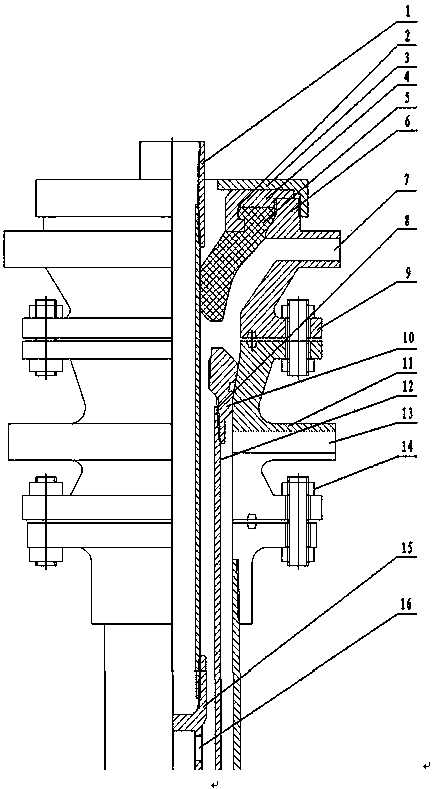

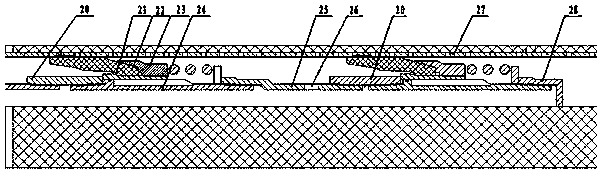

[0020] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0021] according to Figures 1 to 3 , the horizontal well open hole screen breakage detection string is mainly composed of a high pressure self-sealing device 2, a liquid flow conversion device 8, a flow blocking packer 21 and a perforated pipe 25.

[0022] The high-pressure self-sealing device 2 is composed of a pressure cap 3 , a self-sealing support ring 4 , a sealing core 5 , a self-sealing body 6 and a self-sealing flange 9 . Wherein, the self-sealing body 6 is provided with a self-sealing outlet 7, which is used as a liquid outflow channel during the detection process. The lower part of the high-pressure self-sealing device 2 is connected with the wellhead spool 11 through the self-sealing flange 10, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com