Milling Cutter Holding Equipment

A technology for clamping equipment and milling cutters, applied in the direction of metal processing equipment, clamping, clamping devices, etc., to reduce the probability of damage, avoid the tilting of milling cutters, and avoid the effects of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

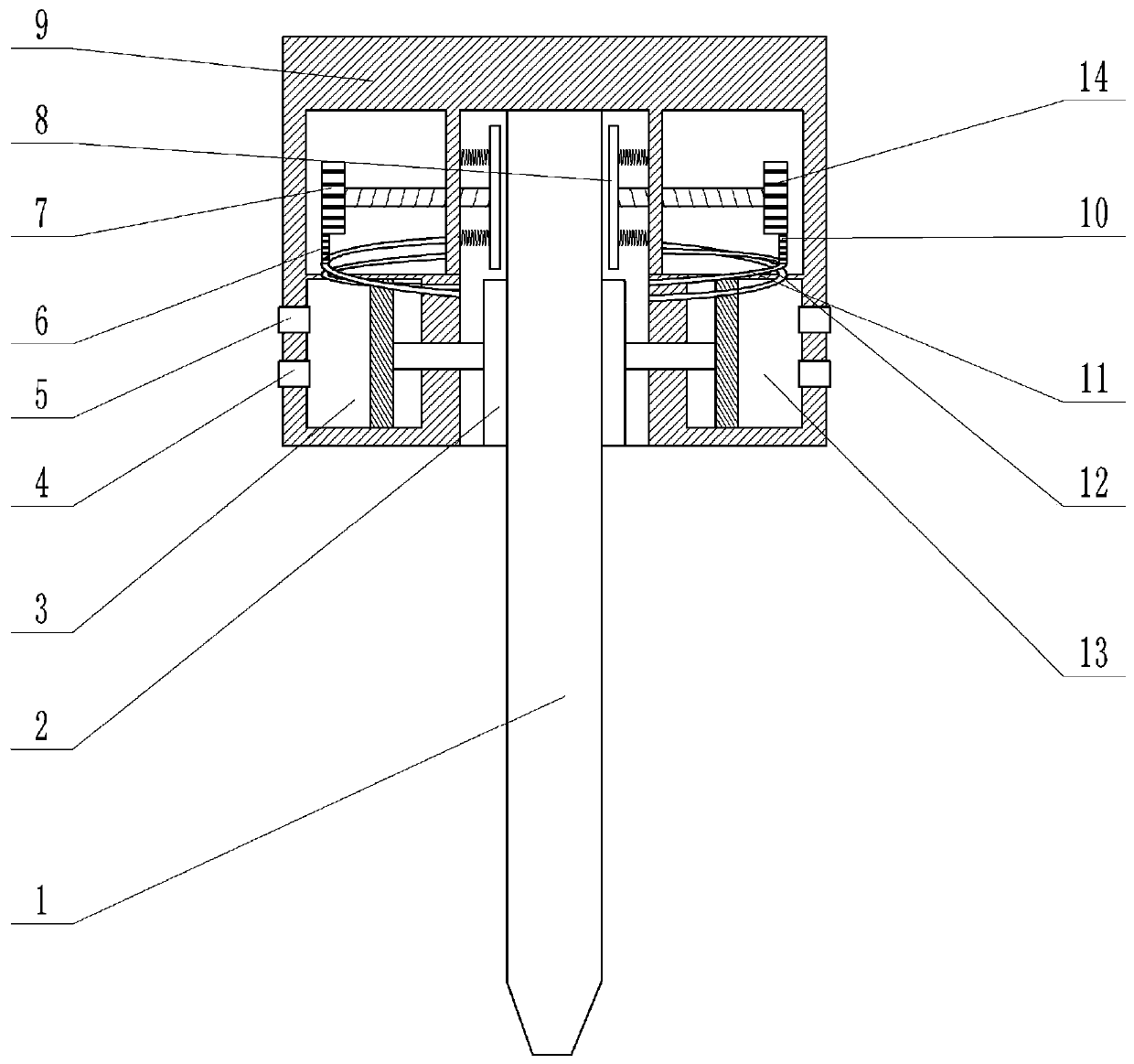

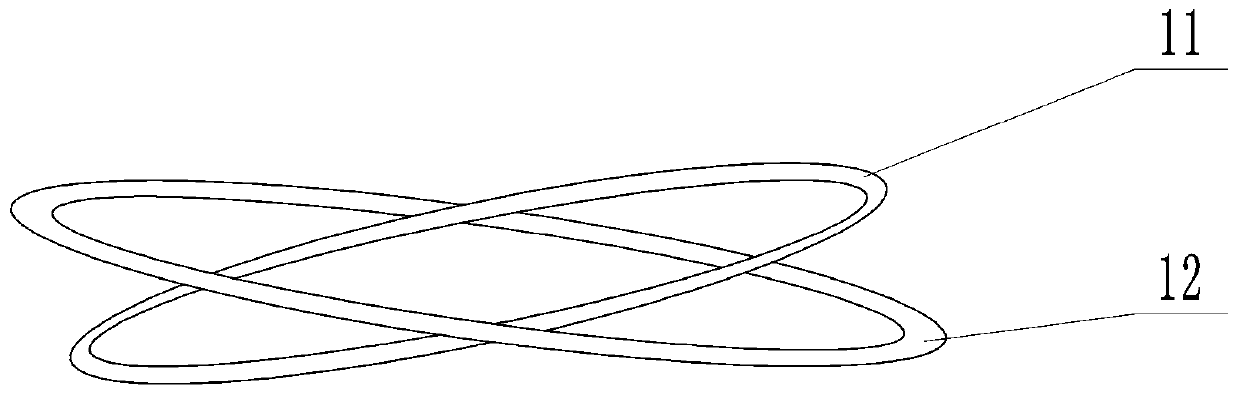

[0028] The embodiment is basically as attached figure 1 And attached figure 2Shown: milling cutter clamping equipment, including a frame 9, the center of the frame 9 is provided with a passage for the milling cutter 1 to pass through, and the top of the passage is provided with a pentagonal blind hole matching the shape of the top end of the milling cutter 1. The side is provided with an adjustment chamber and a cylinder from top to bottom. A clamping plate 2 for clamping and fixing the milling cutter 1 is fixedly installed on the piston rod of the cylinder. The contact surface between the clamping plate 2 and the milling cutter 1 is an arc surface , the cylinder includes the first cylinder 3 on the left side of the milling cutter 1 and the second cylinder 13 on the right side, and the upper side walls of the first cylinder 3 and the second cylinder 13 are respectively provided with venting ports 17 for gas in and out; The side wall is provided with a detection piece 8 for c...

Embodiment 2

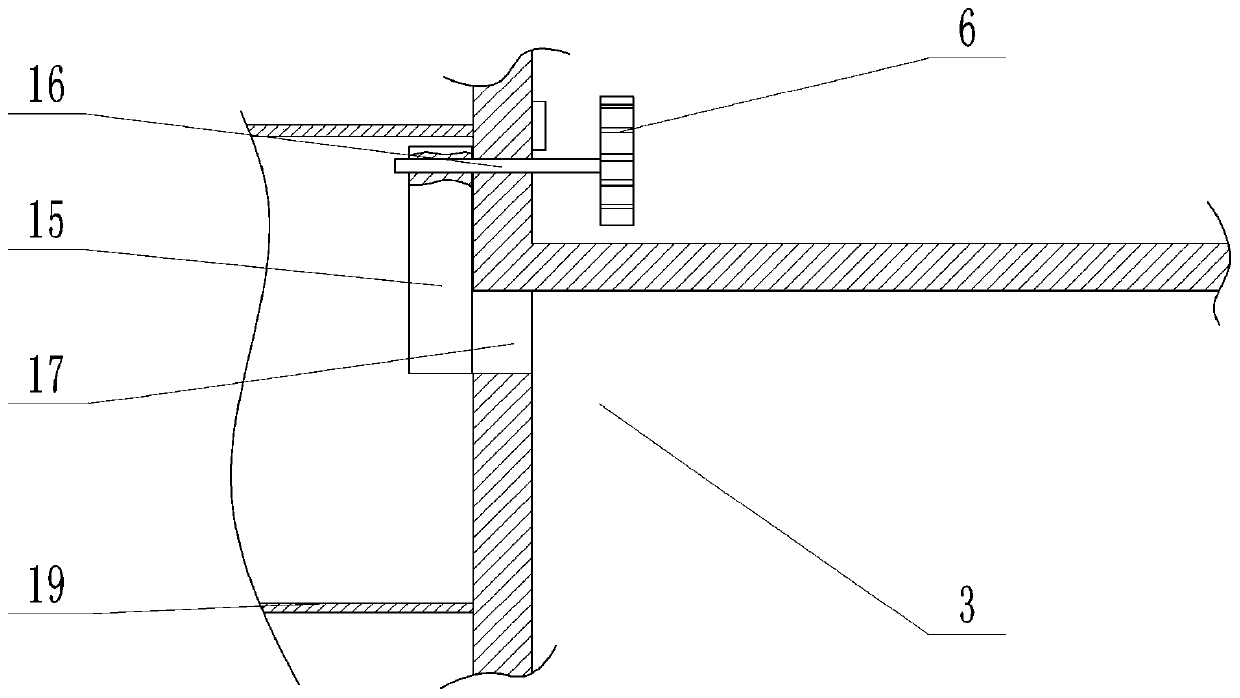

[0035] as attached image 3 As shown, the difference between the second embodiment and the first embodiment is that there is no annular slideway, the first slide ring 12 and the second slide ring 11 in the second embodiment, the left side wall of the first cylinder 3 and the right side of the second cylinder 13 There is an air release port 17 on the side wall, and the shaft 16 of the first pinion 6 and the second pinion 10 is connected with an eccentric wheel 15 covering the air release port 17. The connecting pipe 19 (attached image 3 The second cylinder 13, the second pinion 10, etc. are not all drawn).

[0036] During specific implementation, if the installed milling cutter 1 deviates to the left, the rotation of the first pinion 6 will cause the eccentric wheel 15 connected on the rotating shaft 16 of the first pinion 6 to deflect, and the eccentric wheel 15 will deflect to make the air release port 17 Open, the gas in the high-pressure gas tank enters the first cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com