Performance detection device and method for multi-layer winding system for steel wire rope of dual-broken line reel

A technology for detecting device and system performance, applied in the direction of measuring device, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as inability to obtain test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

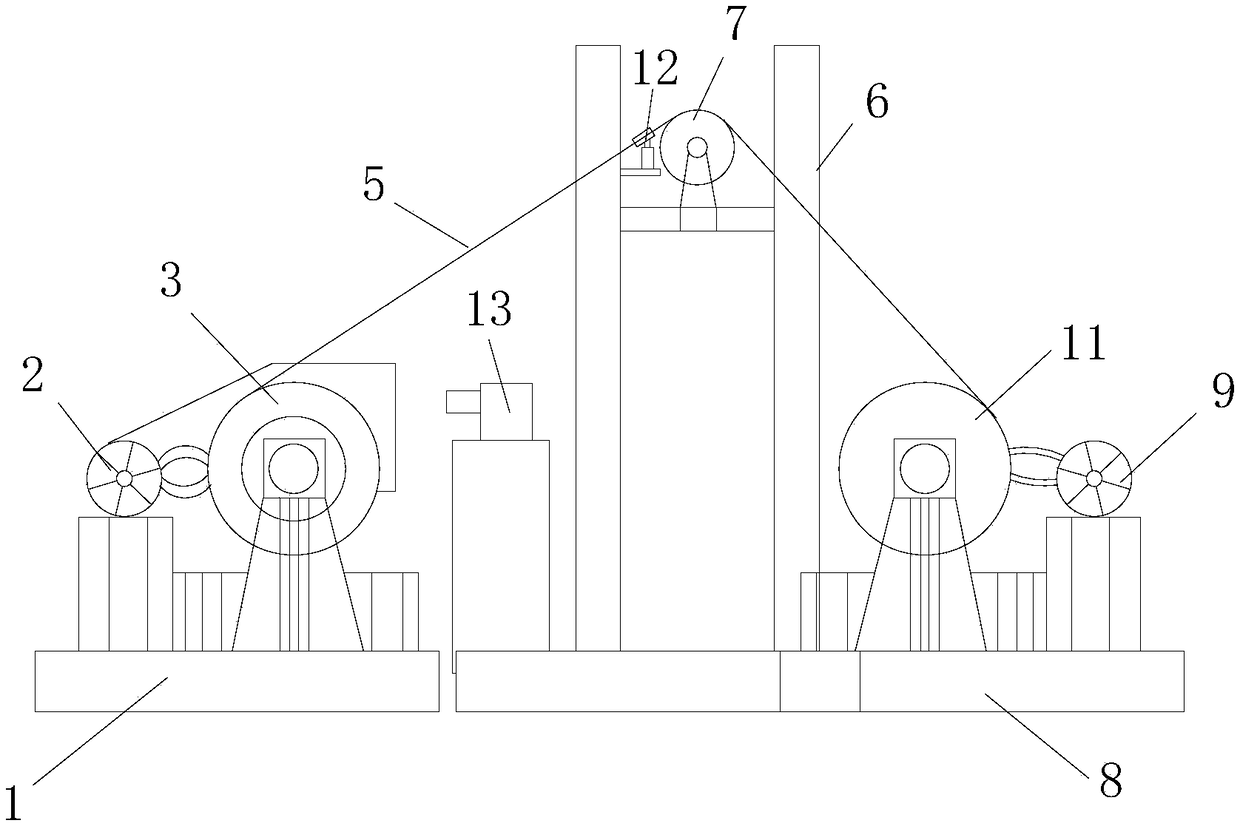

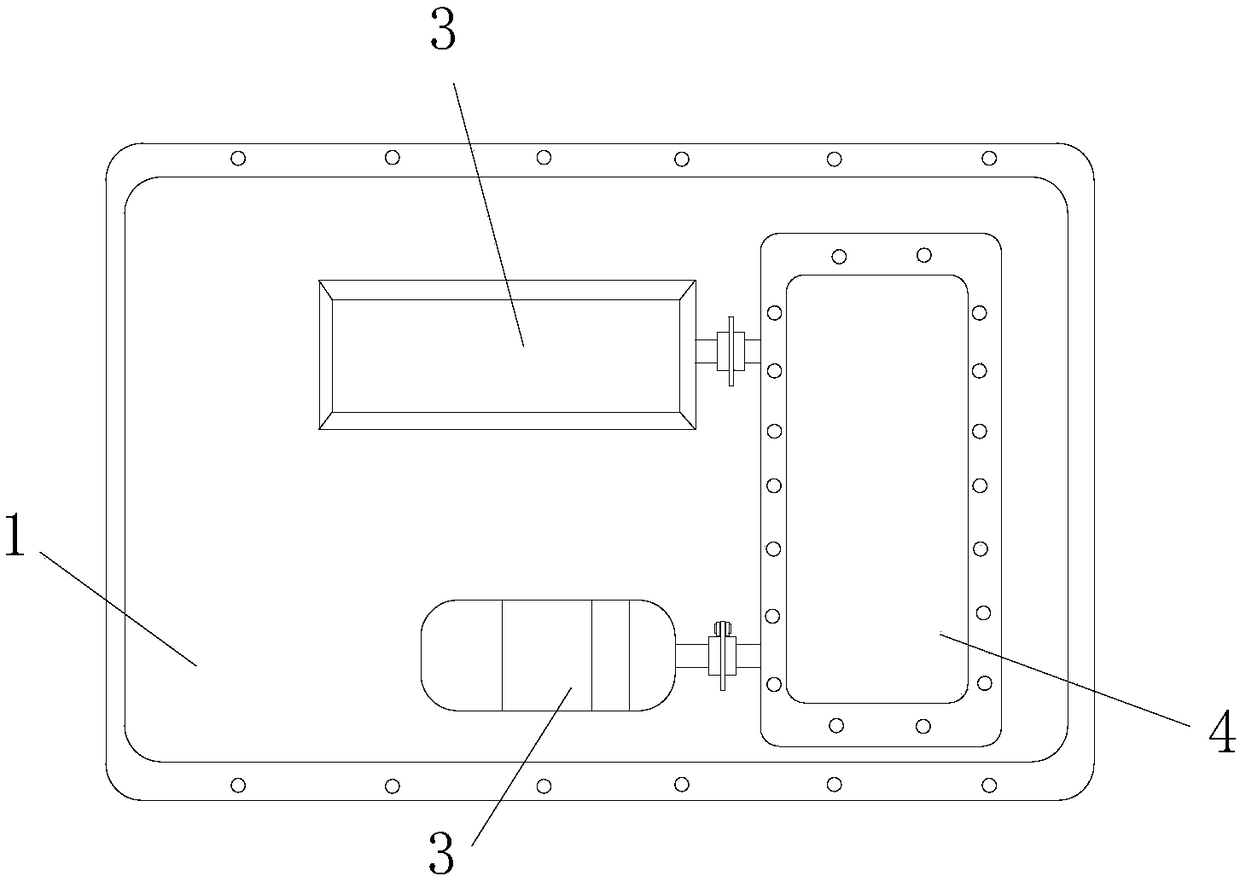

[0036] Such as Figure 1-4 As shown, the performance detection device of the double-broken wire drum multi-layer winding system includes a drive assembly, a load assembly, a pulley assembly, a control cabinet and a host computer; the pulley assembly is located between the drive assembly and the load assembly.

[0037]Described driving assembly comprises driving platform base 1, and the driving motor 2 that is arranged on driving platform base 1, the first speed reducer 4 and double broken line reel support, the output shaft of driving motor 2 is connected with the first speed reducer through coupling The input shaft of 4 is connected; the double-broken reel 3 to be tested is placed on the double-broken reel support, and the output shaft of the first reducer is connected to the rotating shaft of the double-broken reel to be tested through a coupling.

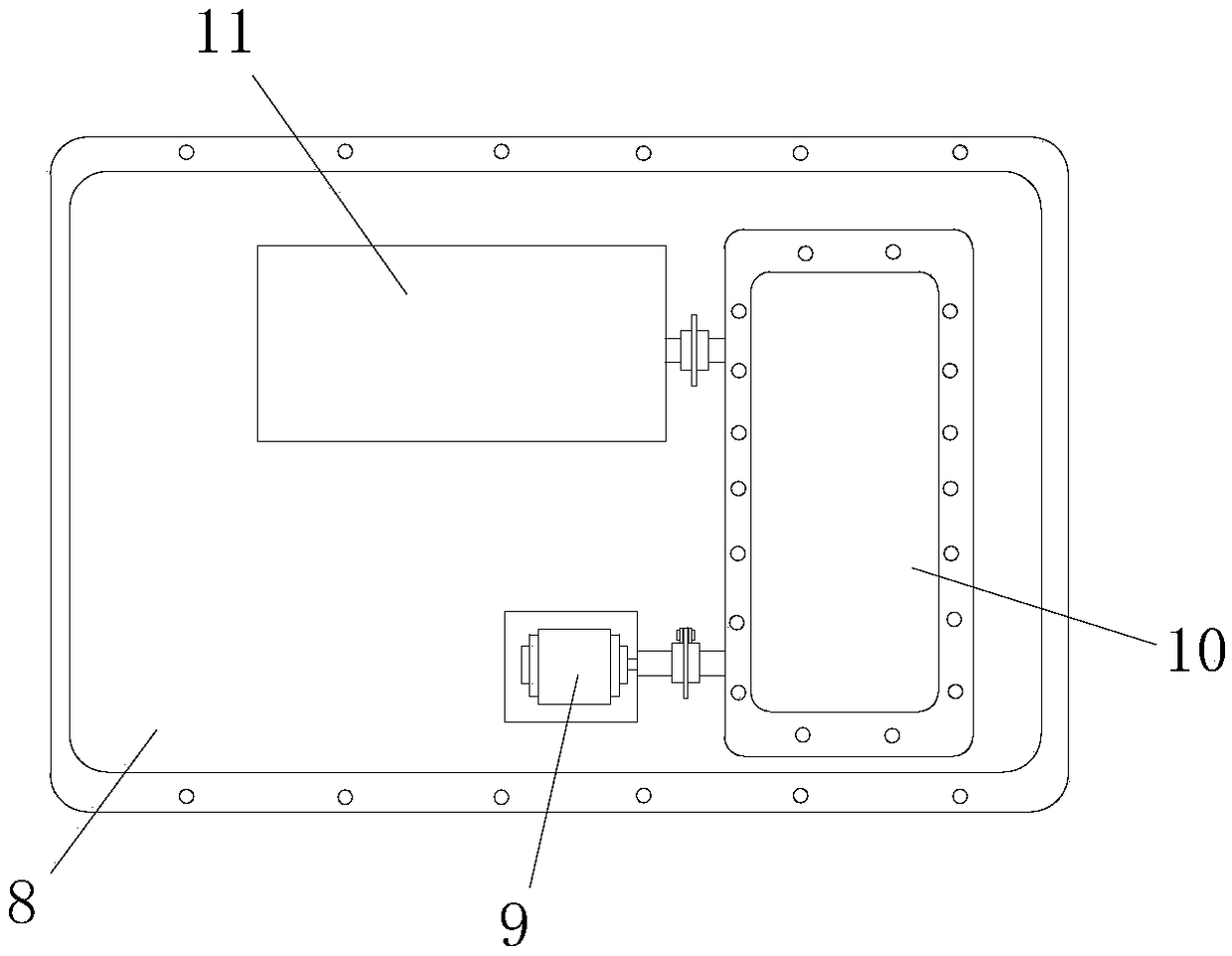

[0038] The load assembly includes a load platform base 8, and an eddy current power machine 9, a second speed reducer 10, and a...

Embodiment 2

[0047] The detection method based on above-mentioned testing device, comprises the steps:

[0048] Step 1. Place the double-broken reel to be detected on the double-broken reel support, and connect the rotating shaft of the double-broken reel to the output shaft of the first reducer;

[0049] Step 2. Turn on the inverter, PLC controller, host computer, drive motor, eddy current machine, high-definition camera, pin sensor, magnetoresistive sensor, resistive strain gauge and acceleration sensor;

[0050] The driving motor and the eddy current machine rotate in the same direction. The steel wire rope wound on the double-broken reel to be tested is wound out from the double-broken reel to be tested, and wound into the smooth reel after passing through the middle fixed pulley; during this process, The pin shaft sensor collects the stress value of the steel wire rope, the magnetic resistance sensor collects the wear and cross-sectional area change information of the steel wire rope,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com