A dynamic loading device for model testing of pile-supported towering structures

A technology of loading device and structural model, which is applied in the test of foundation structure, foundation structure engineering, construction, etc., can solve the problems of unrealistic simulation of pile foundation load, neglect of load space variability, and increased difficulty of model test, etc. Achieve the effects of small footprint, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

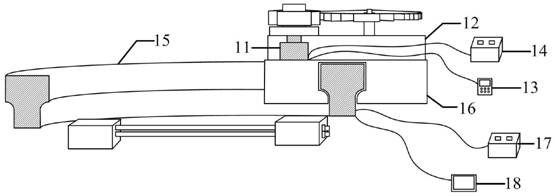

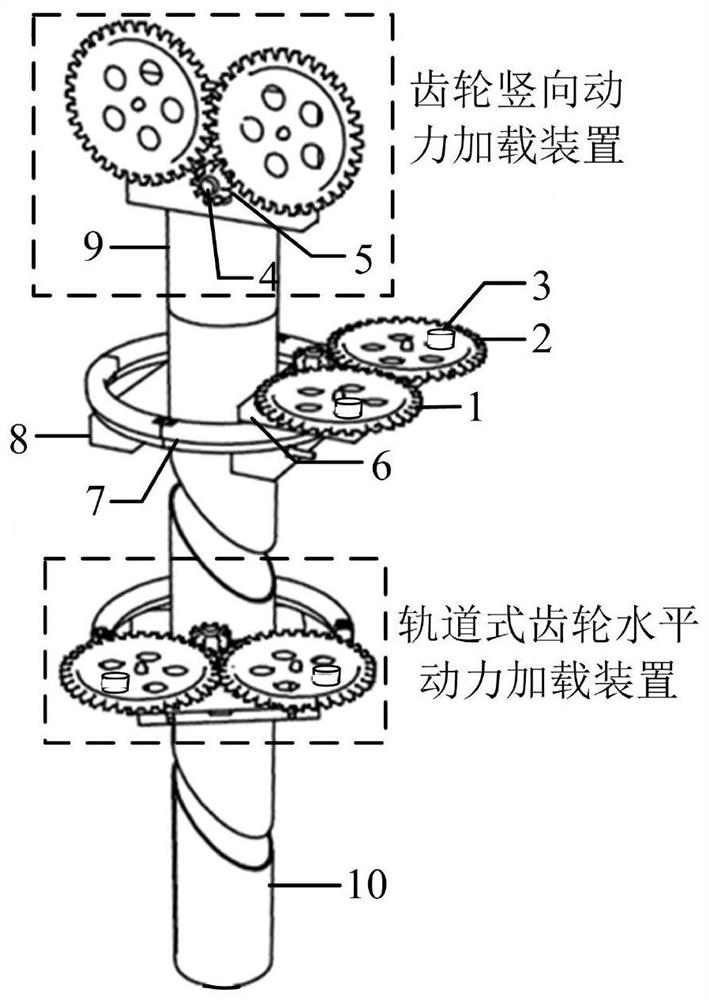

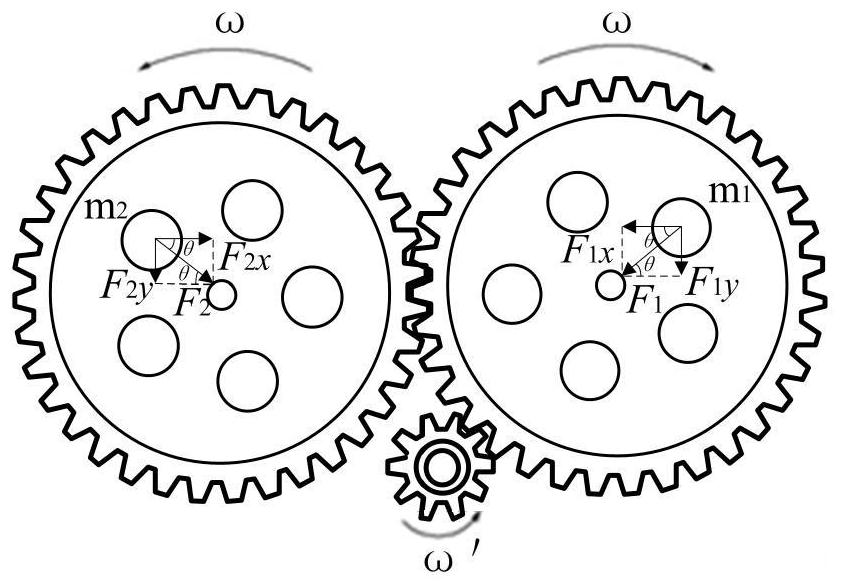

[0017] The main structure of this embodiment consists of an orbital gear horizontal power loading device and a gear vertical power loading device mounted on the tower 10. The orbital gear horizontal power loading device includes an active force application gear 1, a passive force application gear 2, a mass Block 3, transmission shaft 4, transmission gear 5, speed regulating motor loading system 6, numerical control ring track 7 and splint tray 8, the active force application gear 1 and the passive force application gear 2 with the same structure mesh with each other to form a force application gear pair, A mass block 3 is symmetrically installed on the active force-applying gear 1 and the passive force-applying gear 2, respectively, the transmission gear 5 and the active force-applying gear 1 are engaged with each other, and the force-applying gear pair and the transmission gear 5 form a gear group; The system 6 includes a micro motor 11, a high-strength alloy box 12, a digital...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com