Rotary earth sampling research device

A rotary, soil-based technology, applied in the direction of sampling devices, etc., can solve the problems of small stones obstructing soil digging and sampling, landfilling soil is time-consuming and labor-intensive, and achieves the effects of convenient classification and placement, low manufacturing cost and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

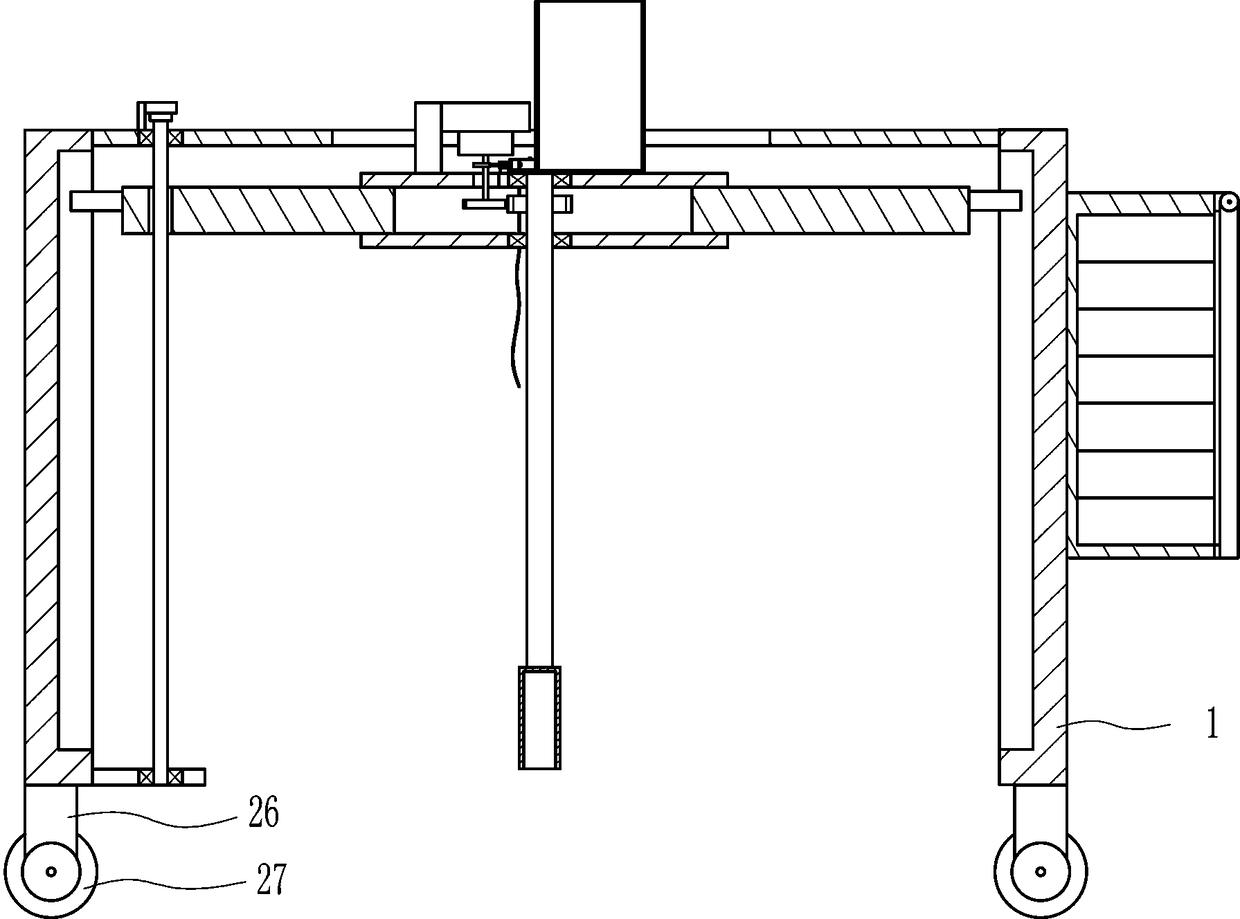

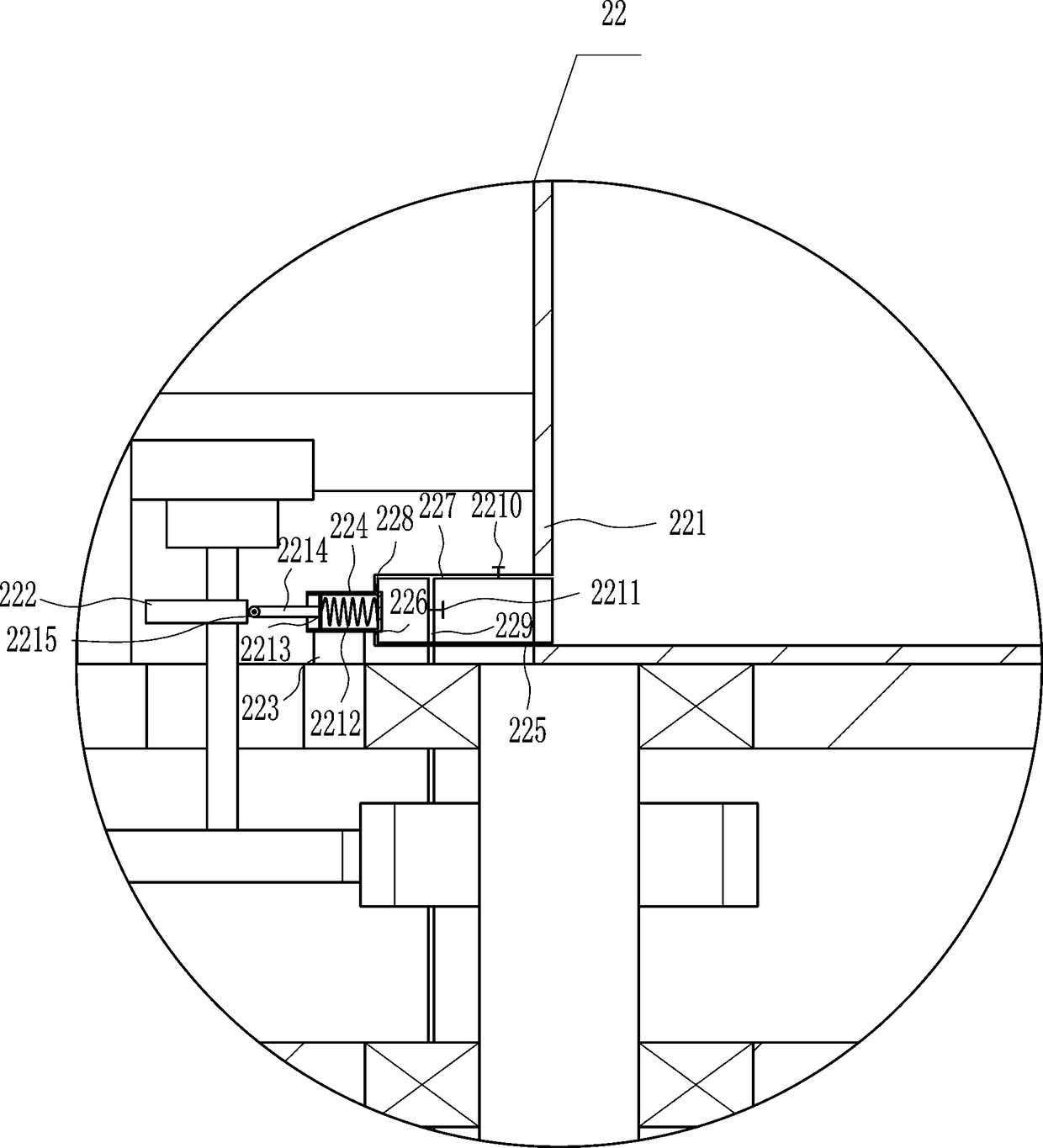

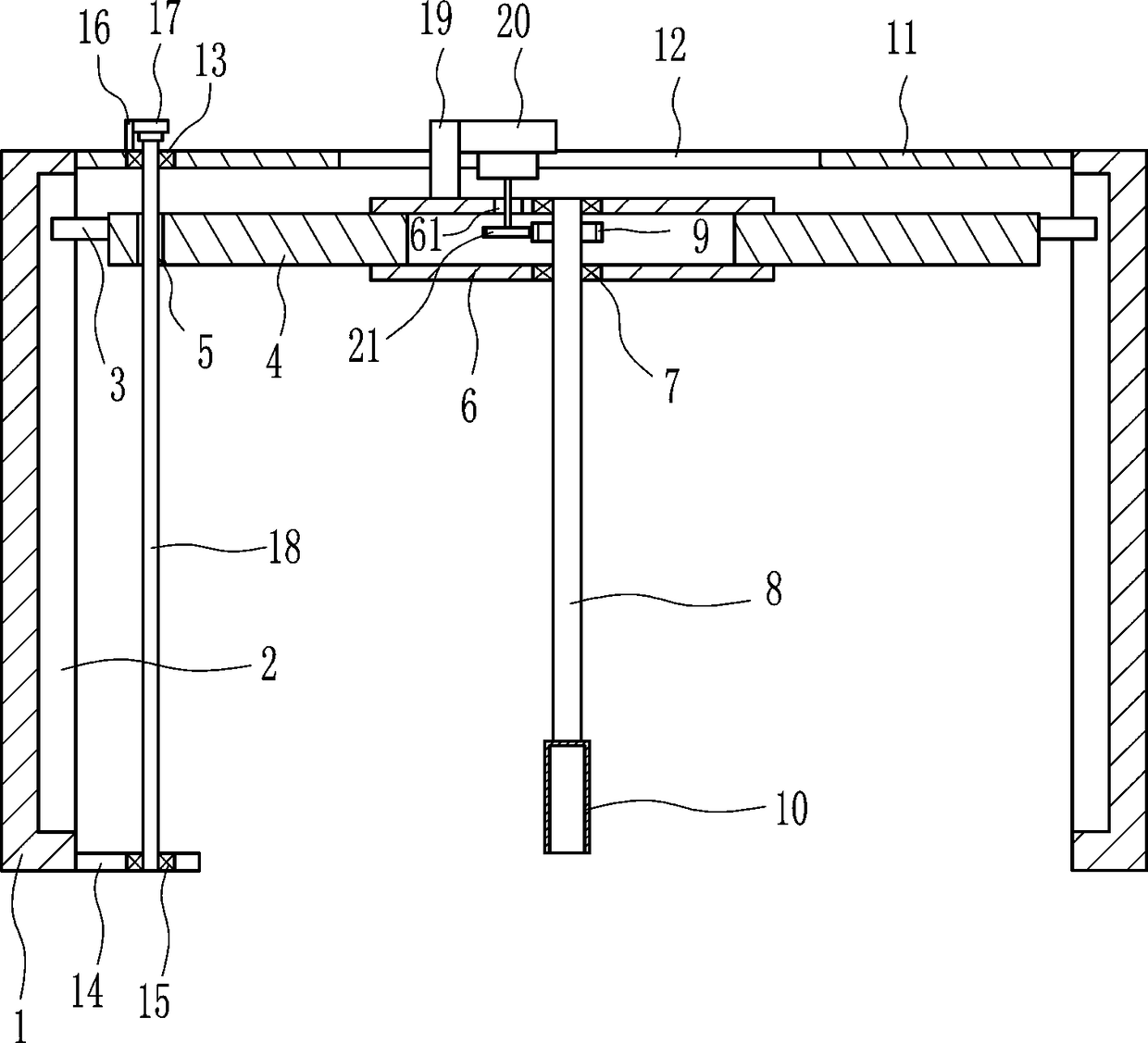

[0024] A rotary soil sampling research device, such as Figure 1-5As shown, it includes a U-shaped bracket 1, a first slide rail 2, a first slider 3, a first fixed plate 4, an elongated frame 6, a first bearing 7, a shaft 8, a first straight gear 9, and a sampling bucket 10. Support plate 11, second bearing 13, first cross support plate 14, third bearing 15, first mounting plate 16, first motor 17, screw 18, second mounting plate 19, second motor 20 and second The spur gear 21 is symmetrically provided with U-shaped brackets 1 on the left and right sides. The inner sides of the U-shaped brackets 1 on the left and right sides are fixedly connected with a first slide rail 2, and the first slide rails 2 on the left and right sides are equipped with a first slide rail 2. A slider 3, the first slider 3 on the left and right sides is fixedly connected with a first fixed plate 4, the first fixed plate 4 on the left and right sides is located in the left and right sides of the elongat...

Embodiment 2

[0026] A rotary soil sampling research device, such as Figure 1-5 As shown, it includes a U-shaped bracket 1, a first slide rail 2, a first slider 3, a first fixed plate 4, an elongated frame 6, a first bearing 7, a shaft 8, a first straight gear 9, and a sampling bucket 10. Support plate 11, second bearing 13, first cross support plate 14, third bearing 15, first mounting plate 16, first motor 17, screw 18, second mounting plate 19, second motor 20 and second The spur gear 21 is symmetrically provided with U-shaped brackets 1 on the left and right sides. The inner sides of the U-shaped brackets 1 on the left and right sides are fixedly connected with a first slide rail 2, and the first slide rails 2 on the left and right sides are equipped with a first slide rail 2. A slider 3, the first slider 3 on the left and right sides is fixedly connected with a first fixed plate 4, the first fixed plate 4 on the left and right sides is located in the left and right sides of the elonga...

Embodiment 3

[0029] A rotary soil sampling research device, such as Figure 1-5 As shown, it includes a U-shaped bracket 1, a first slide rail 2, a first slider 3, a first fixed plate 4, an elongated frame 6, a first bearing 7, a shaft 8, a first straight gear 9, and a sampling bucket 10. Support plate 11, second bearing 13, first cross support plate 14, third bearing 15, first mounting plate 16, first motor 17, screw 18, second mounting plate 19, second motor 20 and second The spur gear 21 is symmetrically provided with U-shaped brackets 1 on the left and right sides. The inner sides of the U-shaped brackets 1 on the left and right sides are fixedly connected with a first slide rail 2, and the first slide rails 2 on the left and right sides are equipped with a first slide rail 2. A slider 3, the first slider 3 on the left and right sides is fixedly connected with a first fixed plate 4, the first fixed plate 4 on the left and right sides is located in the left and right sides of the elonga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com