Shale oil and gas field detection device

A technology for on-site detection and shale oil and gas, applied in the direction of measuring devices, material analysis through electromagnetic means, instruments, etc., can solve the problems of large errors and long time consumption, and achieve moderate volume, high feasibility, great social significance and practicality value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is one of the preferred embodiments of this patent:

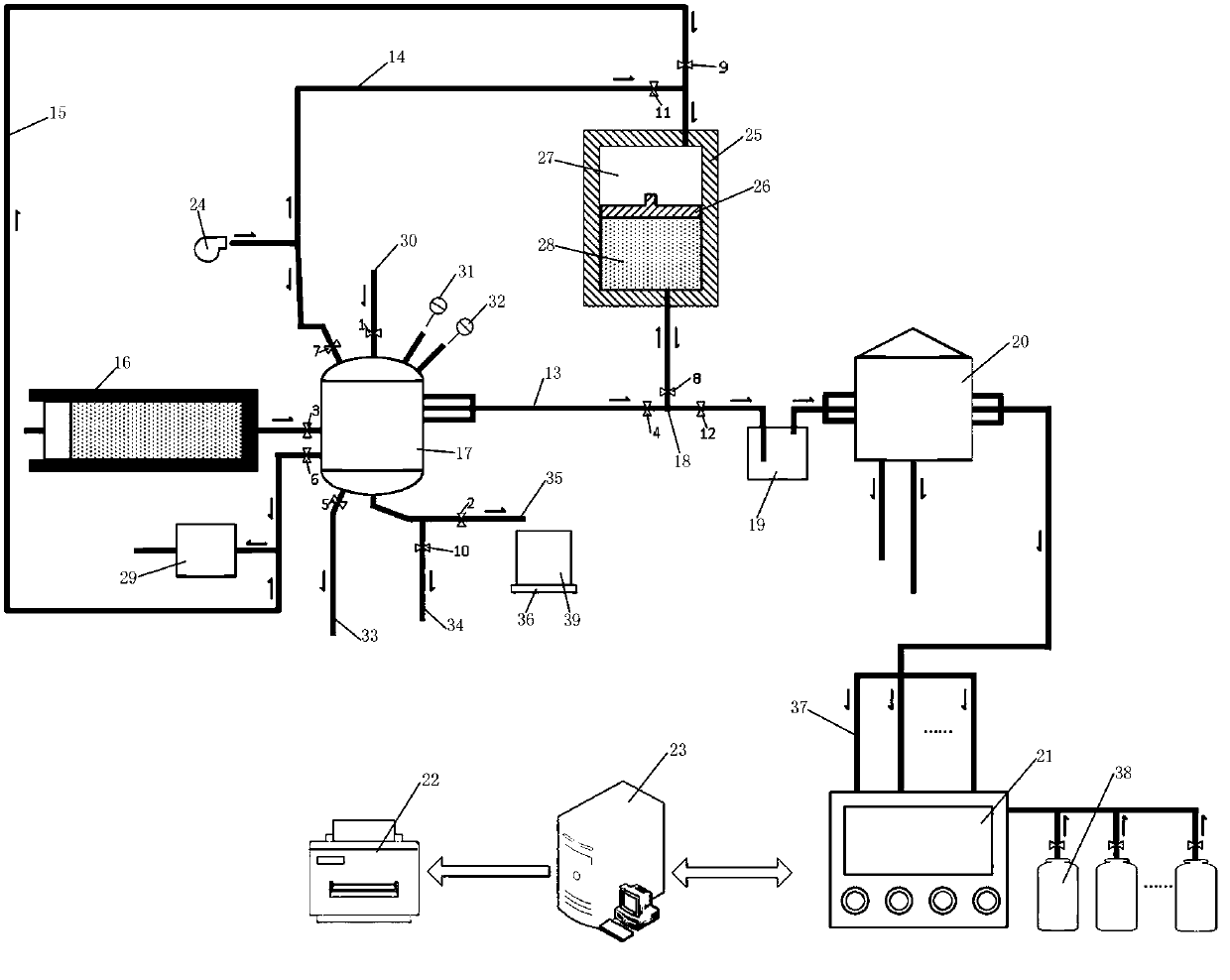

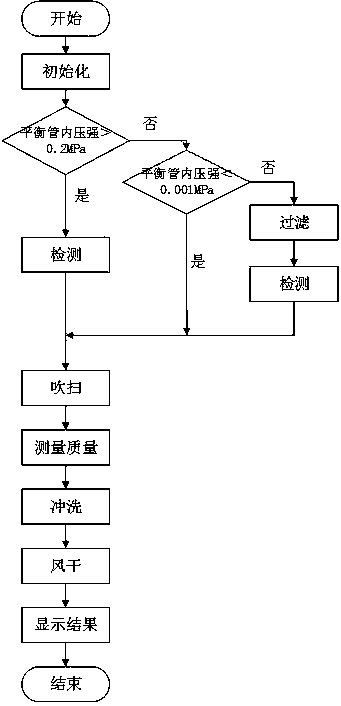

[0037] refer to figure 1 Shown is a shale oil and gas on-site detection device, which includes a gas collector 16, a vacuum pump 29, a blower 24, a pressure balance tank 17, a filter device 19, a cylinder pressurization device 25, a mass spectrometer 21, and an industrial control computer (hereinafter Referred to as the industrial computer 23), the pressure parameter is used as the main control parameter, and the pressure is gradually reduced.

[0038] The first pipeline 13, the first pipeline 13 communicates with the air collector 16, the third solenoid valve 3, the pressure balance tank 17, the fourth solenoid valve 4, the first three-way pipe 18, and the twelfth solenoid valve in sequence from left to right 12. Filtering device 19, pre-filtering device 20, mass spectrometer 21.

[0039]The second pipeline 14 communicates with the pressure balance tank 17, the seventh solenoid valve 7, the second th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com