A protective seat on the tap terminal of a dry-type transformer

A technology of dry-type transformers and protective seats, which is applied in the field of transformers, can solve the problems of increasing manufacturing costs, increasing creepage distances, and distance failures, and achieves the effects of improving utilization, saving costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

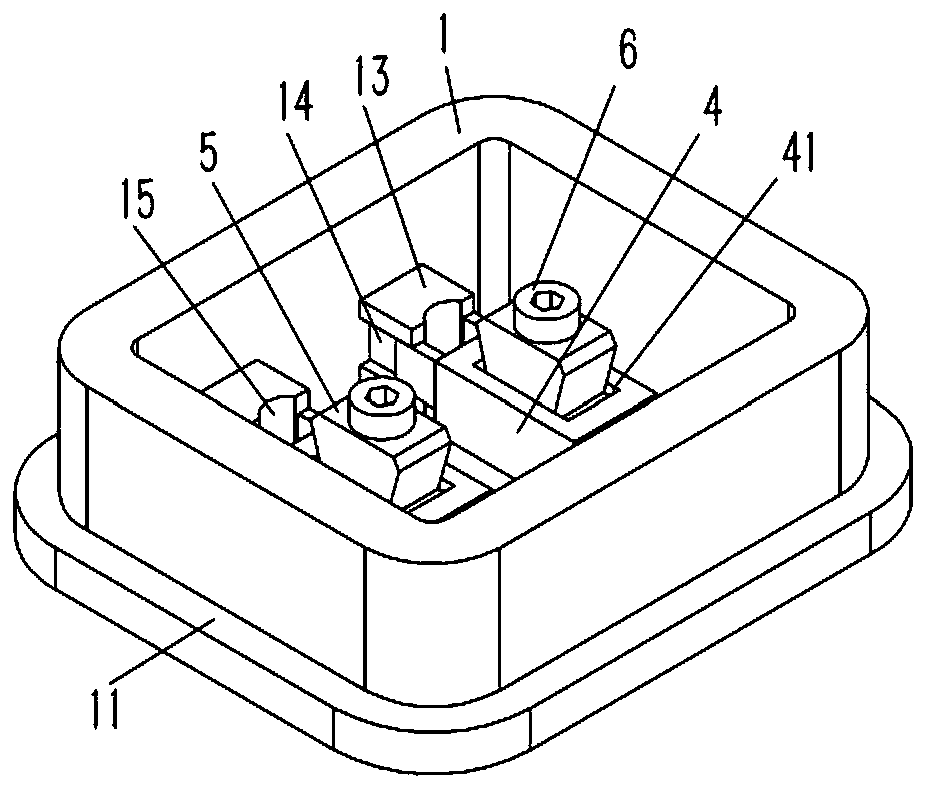

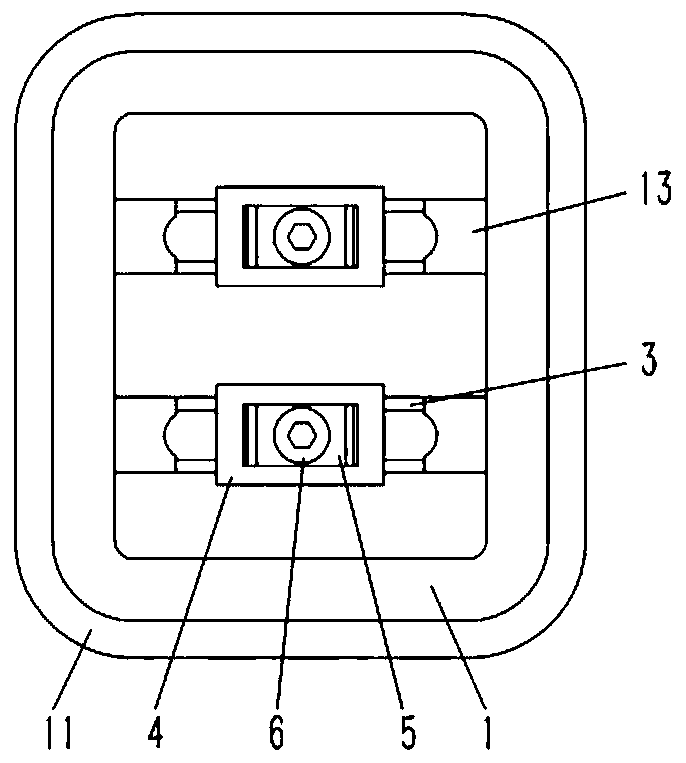

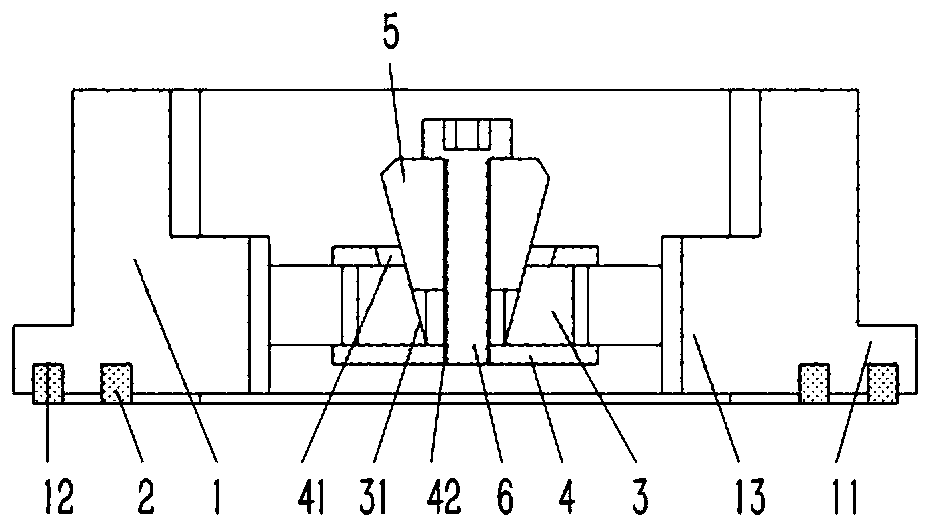

[0018] Example: see Figures 1 to 3 As shown, a protective seat on a tap terminal of a dry-type transformer includes a ceramic seat body 1 in the shape of "back", the lower end of the ceramic seat body 1 is provided with a flange 11, and several " "back"-shaped groove 12, the groove 12 of the ceramic base 1 is inserted and fixed with a sealing ring 2, and several groups of relative positioning blocks 13 are formed on the opposite inner wall of the ceramic base 1, and the two side walls of the positioning block 13 Slots 14 are formed on the top; a rectangular sleeve 4 is provided between the opposite positioning blocks 13 on both sides of the ceramic base 1, and the two ends of the sleeve 4 are inserted with a "匚"-shaped jacket 3, and the jacket 3 The two ends are inserted into the slots 14 of the positioning block 13; the upper end surface of the pipe sleeve 4 is formed with a rectangular notch 41, and the lower end of the pipe sleeve 4 is formed with a threaded hole 42, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com