Machine-mould integrated tyre vulcanizing device

A technology of tire vulcanization and machine-mold integration, which is applied in the direction of fluid pressure actuation devices, etc., can solve problems such as difficulties in the manufacture of hydraulic cylinder blocks, and achieve the effects of meeting various work needs, simplifying locking devices, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

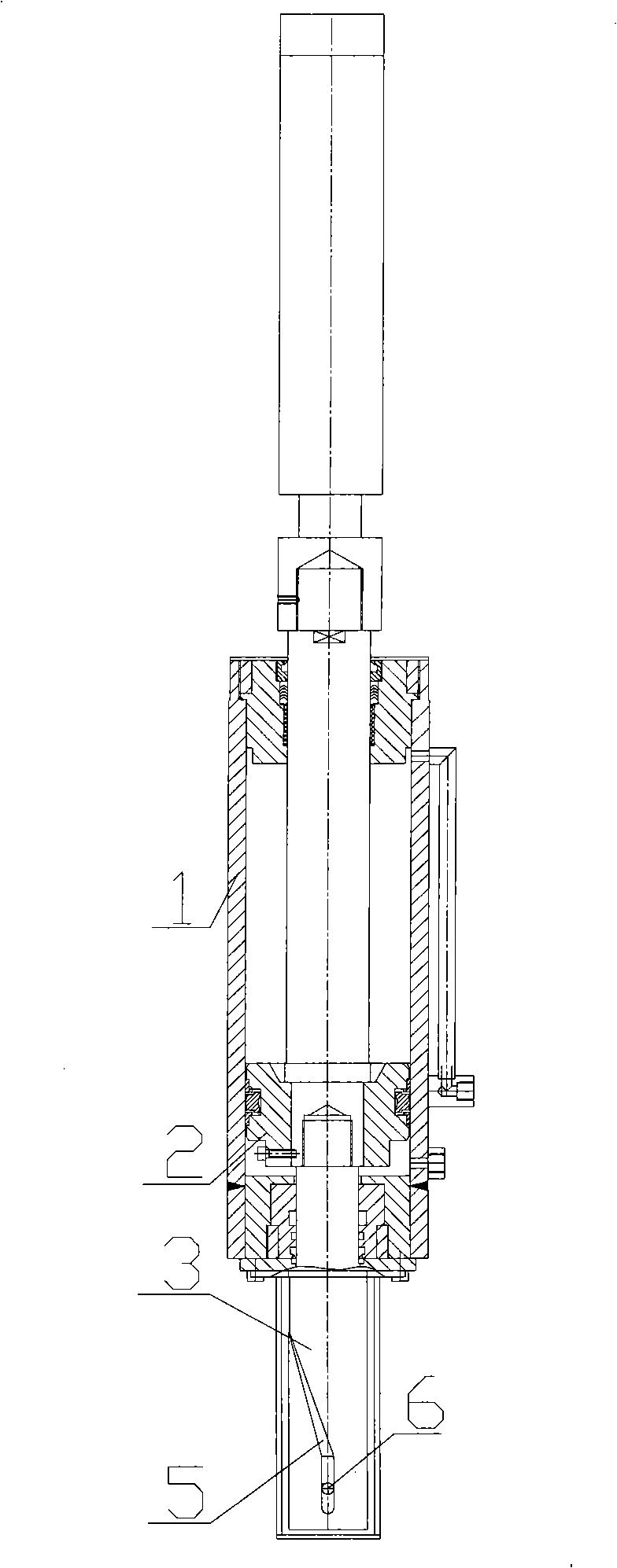

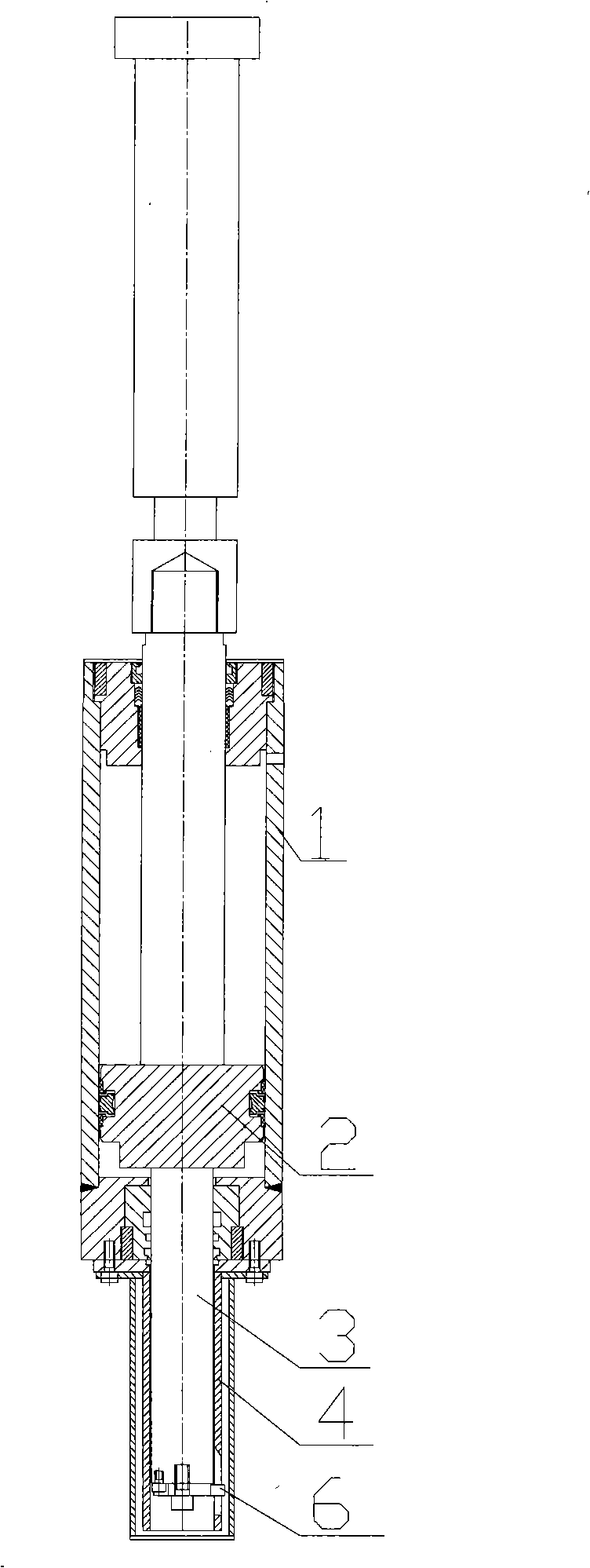

[0015] Such as figure 1 and figure 2 As shown, the hydraulic cylinder includes a cylinder body 1, a piston 2 and a piston rod 3. Piston 2 and piston rod 3 can be made integrally, also can be made separately, and then affixed into one. The two ends of the piston 2 are equipped with piston rods 3, the bottom of the cylinder body 1 is fixedly connected to the piston rod sleeve 4, the piston rod 3 on this side can slide in the piston rod sleeve 4, and the gap between the piston rod 3 and the piston rod sleeve 4 Set the rotation guide device, the structure of the device is shown in the figure, the lower part of the piston rod sleeve 4 is provided with a rotation guide groove 5, and the bottom of the corresponding piston rod 3 is provided with a pin 6, and the pin 6 extends into and is stuck in the rotation guide groove 5 At the same time, the pin 6 can slide along it in the rotation guide groove 5.

[0016] The hydraulic cylinder can be used as a locking device of a mold-integr...

Embodiment 2

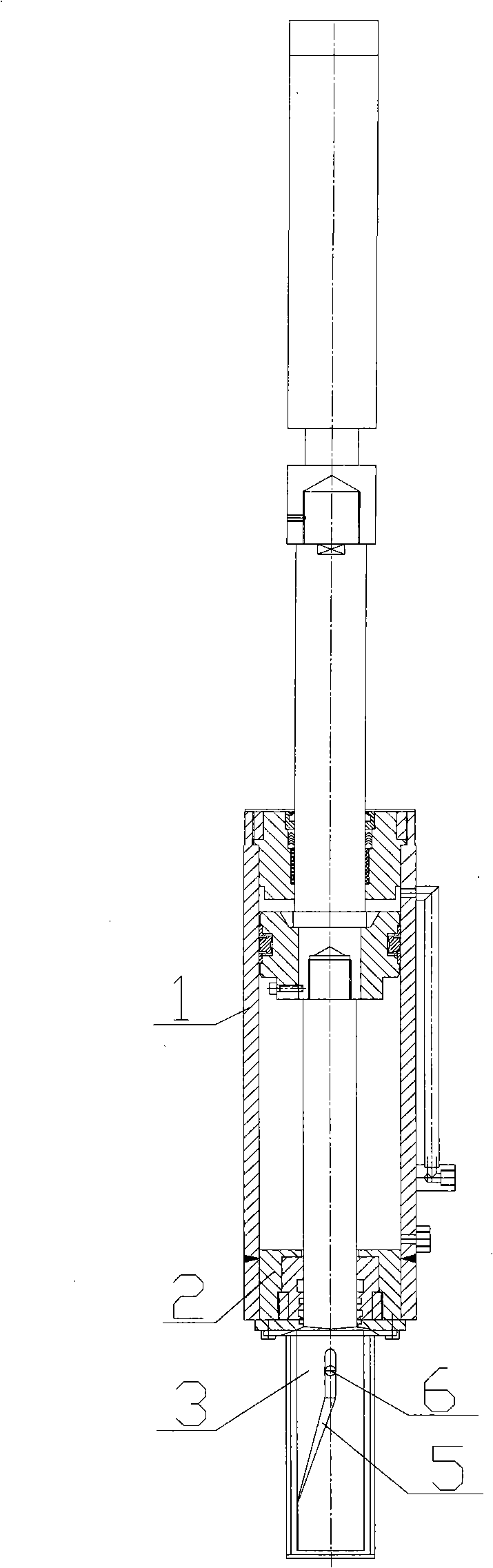

[0019] The rotary guiding device in this embodiment is: one or more rotary guiding grooves 5 are set on the outer surface of the lower part of the piston rod 3, one or more pins 6 are set on the inner surface of the corresponding piston rod sleeve 4, and one end of the pin 6 is connected to The piston rod sleeve 4 is fixedly connected, and the other end is stuck in the rotation guide groove 5, and can slide along the guide groove.

[0020] Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com