Sleeper releasing mechanism, releasing device and sleeper stretching and releasing device

A technology of sleepers and linear guide rails, which is applied in the fields of sleeper tensioning mechanism, sleeper tensioning and tensioning device, and tensioning device, which can solve the problems of sudden tensioning and low efficiency of tensioning devices, and achieve the purpose of prolonging service life and ensuring quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

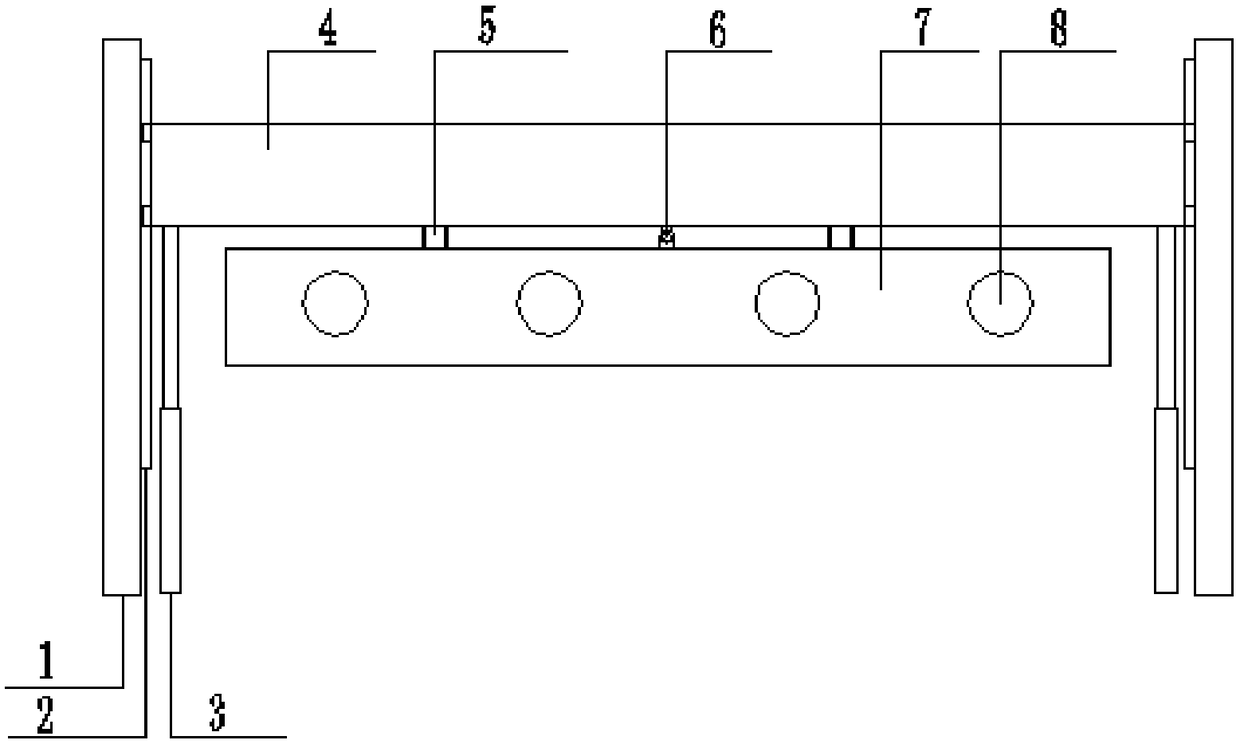

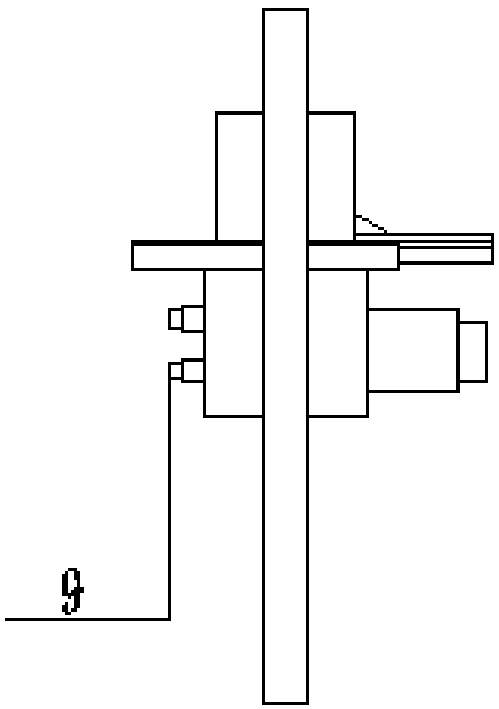

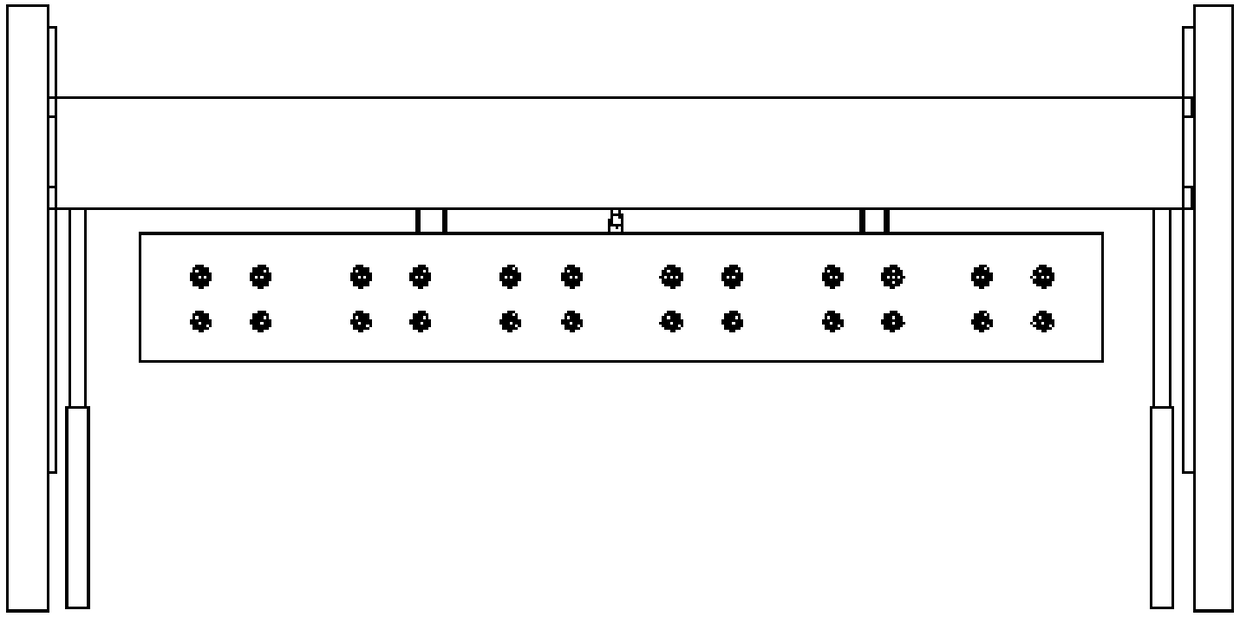

[0030] A sleeper tensioning mechanism, such as Figure 1-Figure 4 As shown, it includes two columns 1, vertical linear guide rails 2 are respectively installed on the inner sides of column 1, and a beam 4 is arranged between the two vertical linear guide rails 2, and the beam 4 moves vertically up and down along the vertical linear guide rails 2 between the two columns 1; the beam 4 There is a gearbox 7 moving in the horizontal direction on the top, the gearbox 7 is powered by a frequency conversion motor 8, and the tension rate can be adjusted through frequency conversion. The output shaft of the gearbox 7 is connected with a plurality of tension couplings 9 .

[0031] In an optional technical solution of this embodiment, the beam 4 is driven by the vertical hydraulic cylinder 3 to move vertically up and down along the vertical linear guide rail 2 .

[0032] In the optional technical solution of this embodiment, there are two vertical hydraulic cylinders 3 , which are respect...

Embodiment 2

[0042] A sleeper tensioning device of the assembly line method, comprising two sets of the above-mentioned sleeper tensioning mechanisms, which are respectively arranged on both sides of the running of the sleeper steel mold. Therefore, the sleeper tensioning device of the assembly line method includes the benefits of the above-mentioned sleeper tensioning mechanism, which will not be repeated here.

Embodiment 3

[0044] A sleeper tensioning device, comprising the above-mentioned sleeper tensioning device and a sleeper prestressed tensioning device. The existing sleeper prestress tensioning device can be used, and the specific structure of the device will not be specifically described here. Therefore, the sleeper tensioning and releasing device includes the advantages of the above-mentioned sleeper tensioning mechanism, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com