Collodion cleaning tool

A cleaning tool and collodion technology, applied in cleaning equipment, cleaning machinery, carpet cleaning, etc., can solve problems such as inability to clean, heavy head weight, inconvenient use, etc., and achieve the effect of improving the stability of placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

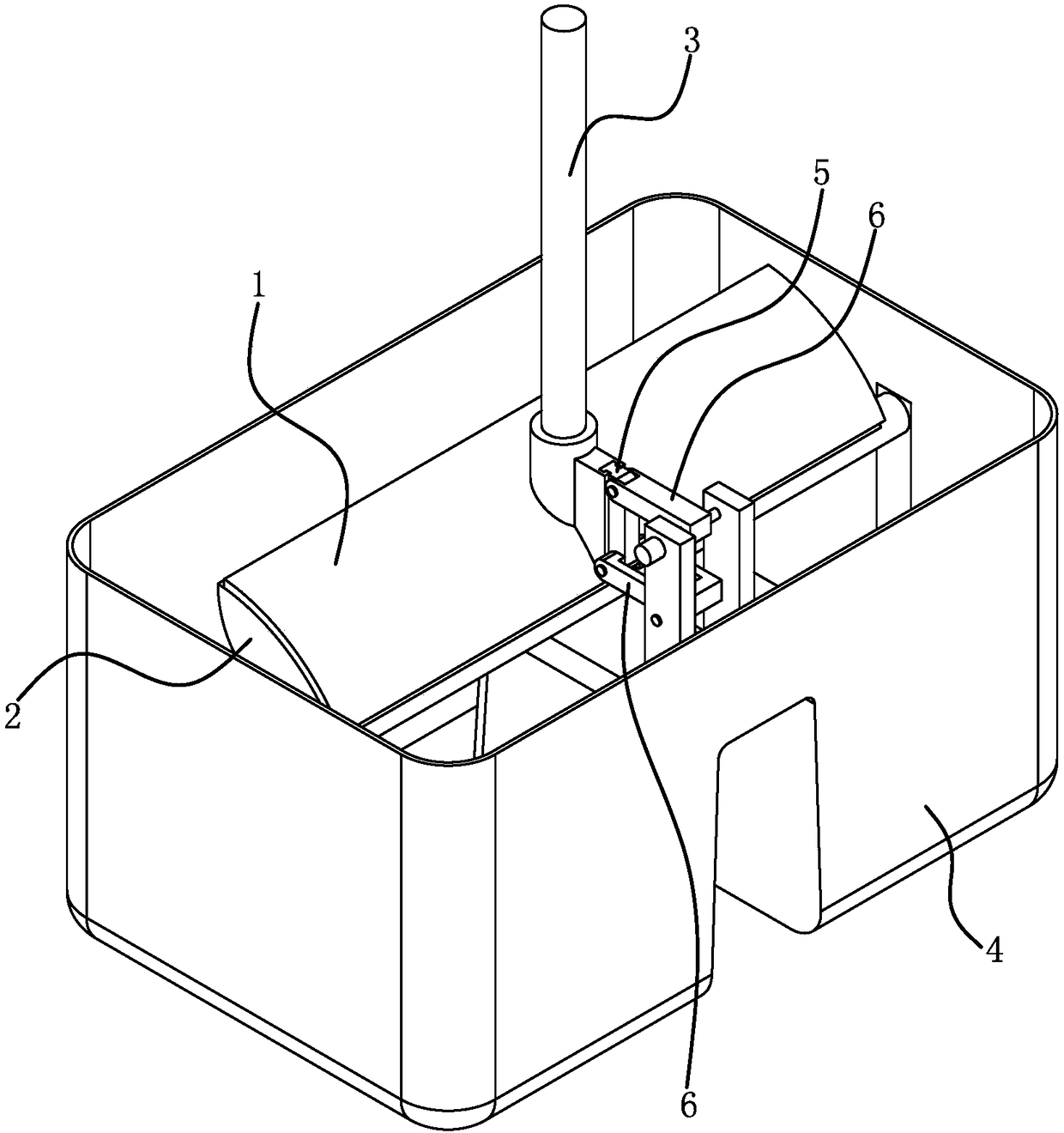

[0027] like Figure 1 to Figure 5 As shown, a collodion cleaning tool includes a cleaning operation part and a water squeezing operation part. The cleaning operation part includes a collodion mounting seat 1, a collodion working head 2 and a handle 3; the water squeezing operation part includes a water squeezing base 4 and a connecting head 5.

[0028] The back of the collodion working head 2 is fixedly connected with the collodion mounting seat 1 , and a handle 3 is installed on the colloidal cotton mounting seat 1 .

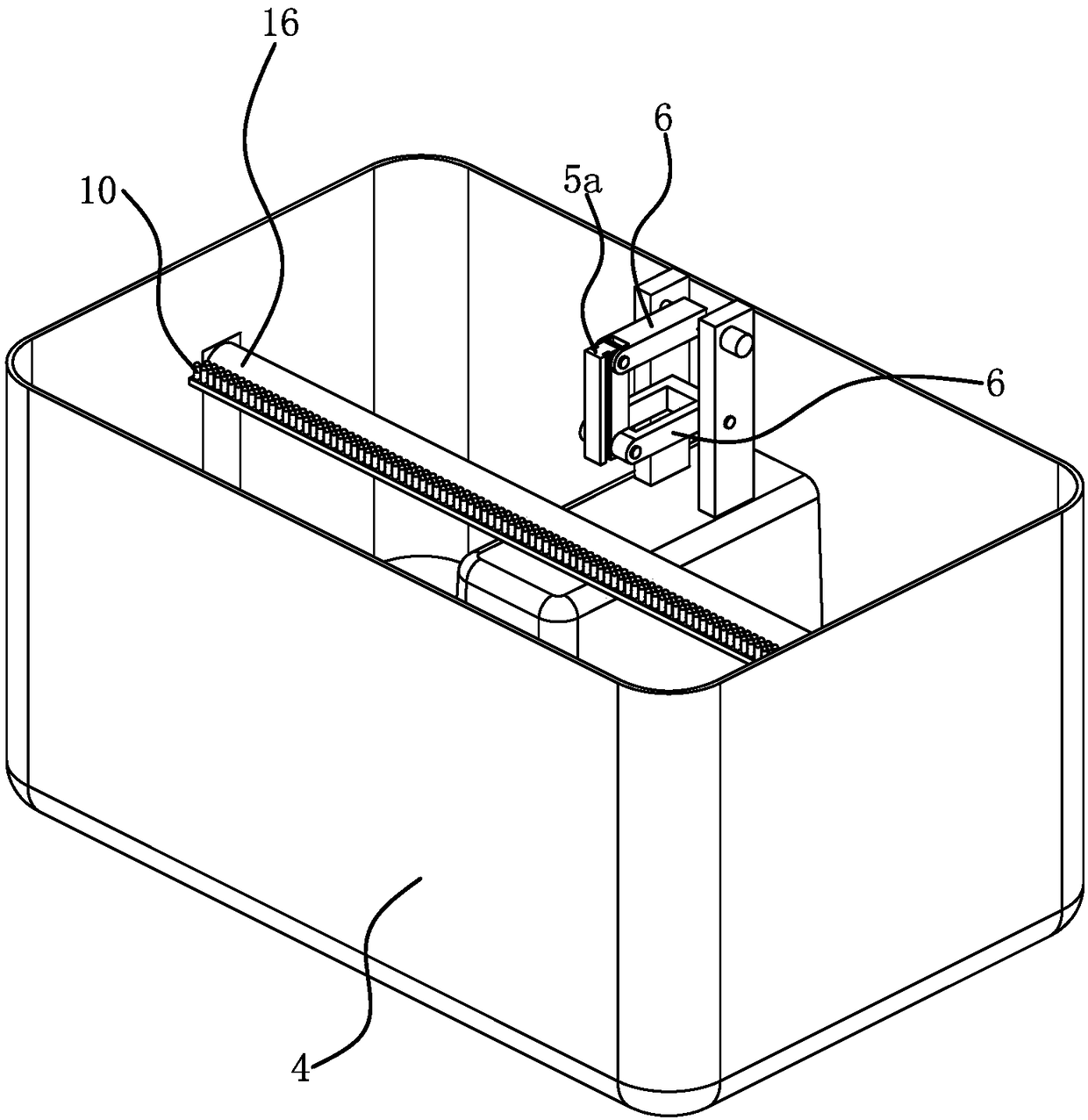

[0029] The water squeezing base 4 is in the shape of a bucket, so that water can be contained in the squeezing base 4 and the water squeezing base 4 can be stably placed on the ground. The squeezing roller 16 and the connecting head 5 are located in the inner cavity of the squeezing base 4 . The water squeezing roller 16 is arranged horizontally, and the water squeezing roller 16 is rotatably connected to the side wall of the water squeezing base 4;

[0030]...

Embodiment 2

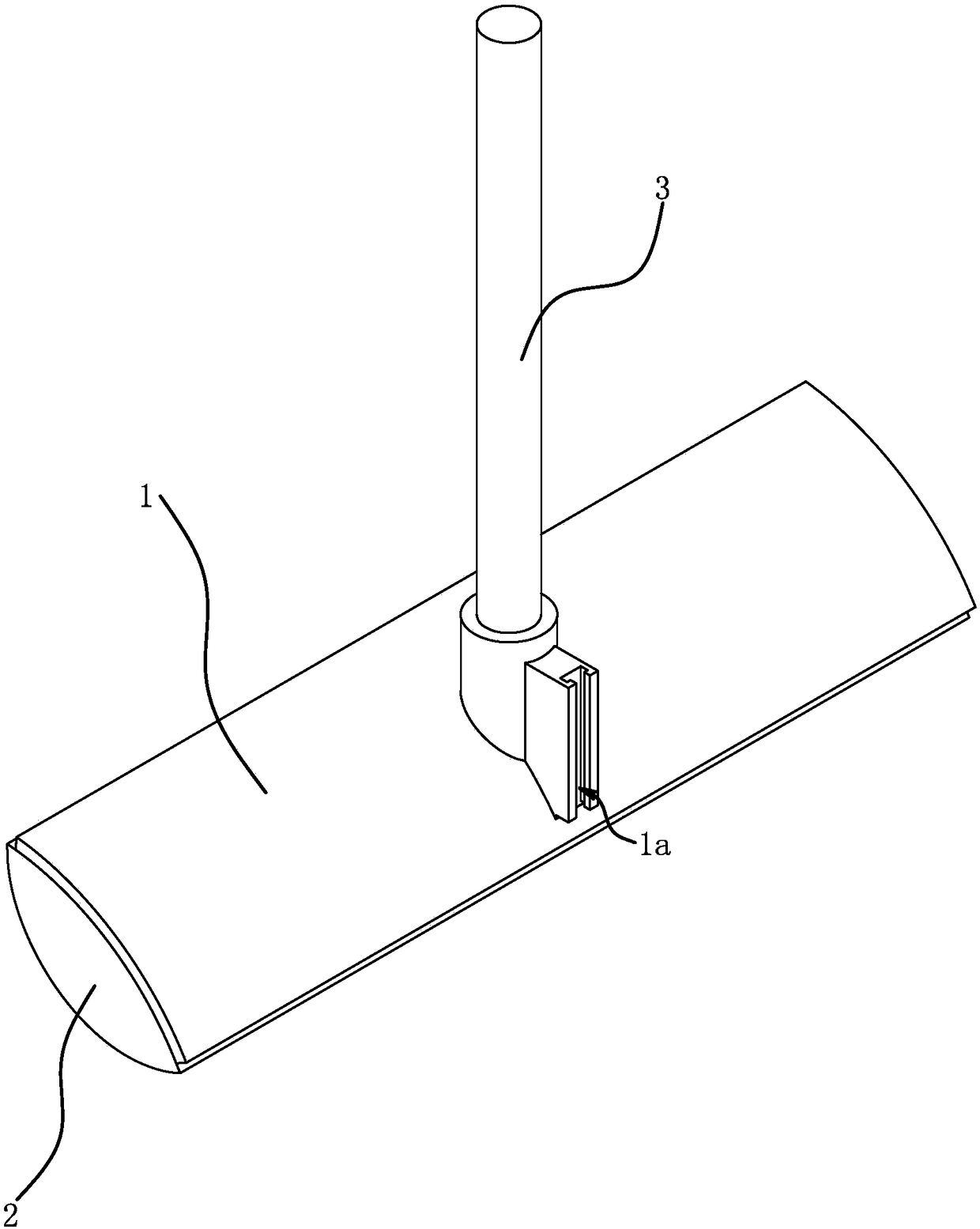

[0038] The structure and principle of this embodiment are basically the same as those of the first embodiment. The basic similarities will not be described redundantly, and only the differences will be described. The differences are as follows: Image 6 and Figure 7As shown, the longitudinal line of the clamping groove 1a on the collodion mounting base 1 is arranged in parallel with the longitudinal line of the collodion working head 2, and the clamping part 5a of the connecting head 5 is also arranged horizontally. When disassembling and assembling the connector 5 and the collodion mount 1, put the collodion mount 1 and the collodion working head 2 into the water squeezing base 4 first, and then move the collodion mount 1 horizontally so that the connector 5 is locked. The head 5a is inserted into the slot 1a of the collodion mount 1 . The structure has the advantages of simple structure and convenient operation.

Embodiment 3

[0040] The structure and principle of this embodiment are basically the same as those of the first embodiment or the second embodiment, and the basic similarities will not be described redundantly, and only the different places will be described. The extension part can be held by people's hands, that is, people hold the extension part by pulling the extension part to force the connecting head 5 to swing, thereby realizing the squeezing roller 16 to squeeze the collodion working head 2; this structure has the advantages of more convenient operation and Easier advantage. The return spring 8 can also be installed between the extension and the water squeezing base 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com